Understanding CNC terminology is crucial for anyone working with or learning about CNC machining. This section covers essential terms and concepts, from basic components to advanced operations, making navigating the technical language of CNC technology easier. Whether you’re a beginner or an experienced machinist, this guide will help clarify key terms, enhancing your knowledge and proficiency in CNC machining processes. Dive in to better understand the language that drives precision engineering and manufacturing.

Axis ⚙️⚙️

In CNC machining, an axis defines a direction of movement, with linear axes (X, Y, Z) for basic motion and rotational axes (A, B, C) for complex, angled machining.

CNC Shop ⚙️⚙️

Discover how CNC shops utilize advanced computer-controlled machinery to produce precise parts from metal, plastic, and wood across various industries.

CNC

Read More

CNC Vacuum Table ⚙️⚙️

A CNC vacuum table is a work-holding device that uses vacuum pressure to securely hold workpieces in place during machining, ensuring stability and precision.

CNC Dust Extraction ⚙️⚙️

CNC dust extraction systems remove dust and debris from machining, enhancing safety, cleanliness, and air quality in CNC operations, especially with dust-prone materials.

CNC Enclosure ⚙️⚙️

A CNC enclosure is a protective cabinet that houses CNC machines, enhancing safety by containing debris, reducing noise, and controlling the machining environment.

CNC Design Software ⚙️⚙️

CNC design software, or CAD, is essential for creating precise digital models used in CNC machining, enabling detailed design, visualization, and efficient production planning.

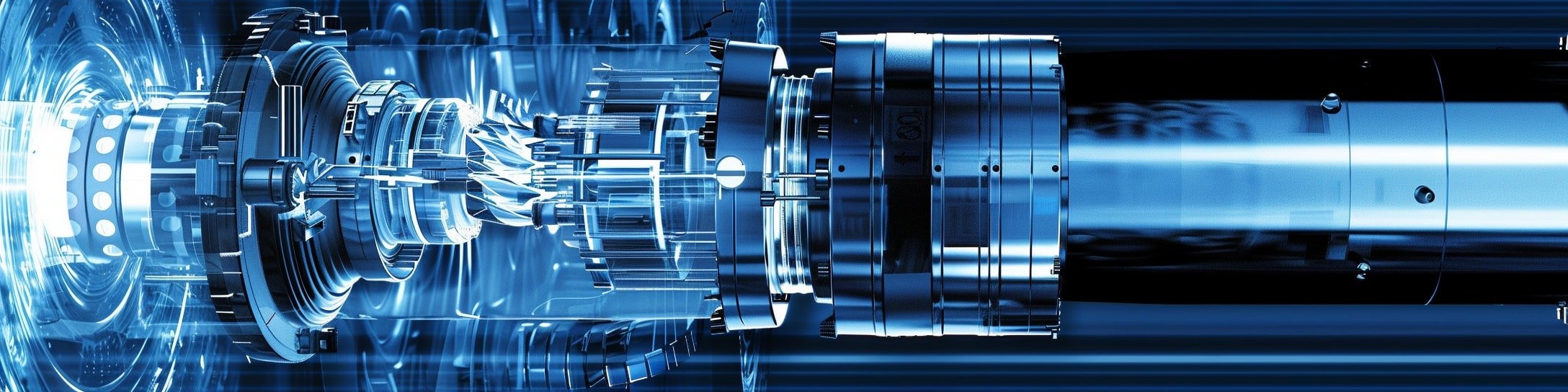

CNC Lathe ⚙️

A CNC lathe is a precision machine tool that uses computer programming to control cutting tools, achieving accurate shaping of rotating workpieces for complex geometries.

CNC EDM ⚙️

CNC EDM (Electrical Discharge Machining) utilizes CNC technology to automate precise, non-contact machining, ideal for complex shapes and hard materials.

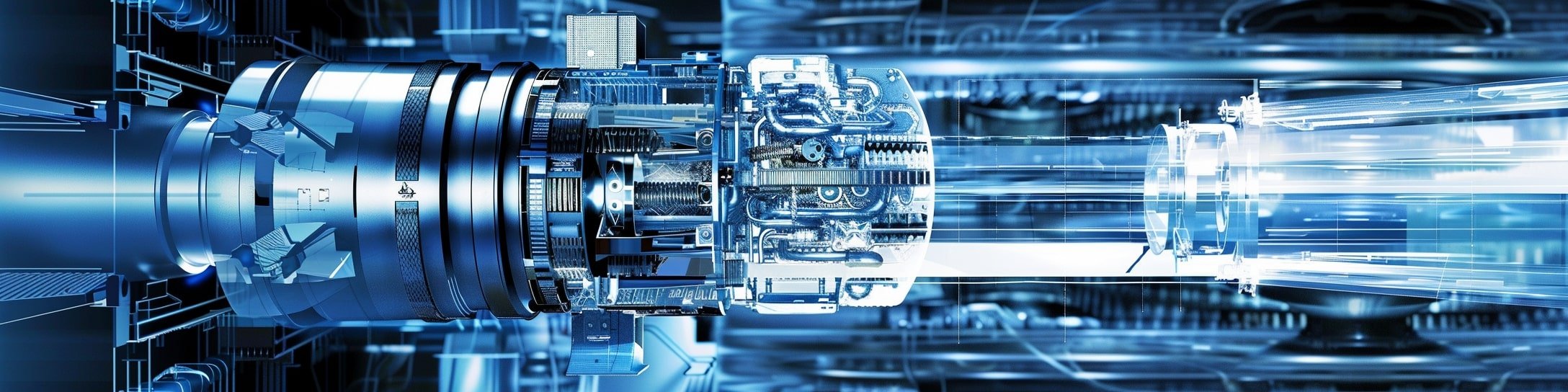

CNC Milling Spindle ⚙️⚙️⚙️

Learn about CNC milling spindles, their function, design, and importance in precise, repeatable machining. Discover key features and operational insights.

CNC Milling Machine ⚙️⚙️⚙️

A CNC (Computer Numerical Control) milling machine is a computer-controlled machine tool used to remove material from a workpiece to create custom parts with complex shapes and profiles.

CNC Plasma Cutter ⚙️

A CNC (Computer Numerical Control) plasma cutter is an automated cutting machine that uses plasma cutting technology to cut through conductive materials, such as metals like steel, aluminium, brass, and copper.

CNC Machining ⚙️

CNC machining is a manufacturing process that uses computer numerical control (CNC) to automate the operation and movement of machine tools, enabling precise and accurate control of machining operations such as milling, turning, drilling, and grinding.

CNC Router ⚙️

A CNC router is a computer-controlled cutting machine used for cutting, shaping, and engraving various materials, such as wood, plastic, and softer metals.

CNC Machine ⚙️

A CNC (Computer Numerical Control) machine is a computer-controlled manufacturing tool that automates the movement and operation of cutting tools to perform various machining processes, such as milling, turning, drilling, and cutting.

CNC Spindle ⚙️

A CNC spindle is a key component driving cutting tools in CNC machines, enabling precise material removal with adjustable speed and power settings.

G-Code ⚙️

G-Code is the programming language that controls CNC machines, detailing precise movements, speeds, and tool actions needed for machining tasks.

Live Tooling ⚙️

Live tooling in CNC lathes allows for powered rotary tools, enabling operations like milling, drilling, and tapping, enhancing versatility and precision in a single setup.

Mach3 ⚙️

Mach3 is a widely used CNC control software that transforms a PC into a CNC machine controller, offering precise motion control for various CNC applications.

Machining Centre ⚙️

A machining centre is a highly automated CNC machine tool capable of performing multiple operations like milling, drilling, and tapping in a single setup for efficient, precise manufacturing.