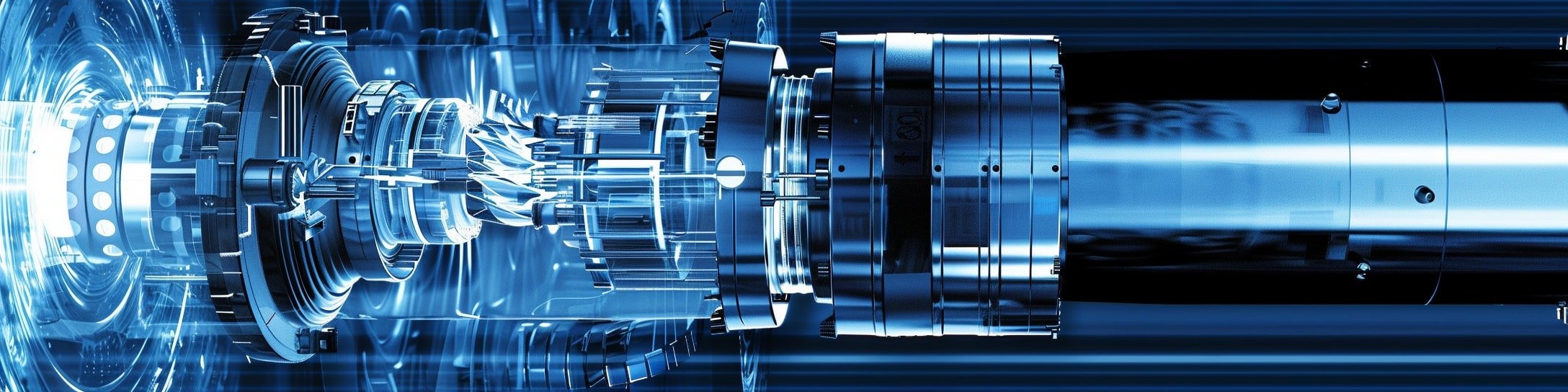

CNC Spindle ⚙️

A CNC spindle is a critical component of a CNC (Computer Numerical Control) machine, essential in CNC mills, lathes, routers, and similar systems. It consists of a rotating shaft that securely holds and drives cutting tools like end mills, drills, or turning tools, allowing precise removal of material from a workpiece according to programmed instructions. The spindle’s main role is to transmit rotational force from the machine’s motor to the cutting tool, making it central to the machining process.

Key Characteristics of CNC Spindles

Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), determines how fast the cutting tool rotates. Higher speeds can improve cutting efficiency and surface finish but may also increase heat and tool wear. CNC machines typically offer adjustable spindle speeds to optimize cutting based on material type and machining requirements.Spindle Power

Spindle power, measured in horsepower or watts, affects the cutting force. Higher-powered spindles can manage tougher materials and more demanding cuts, directly enhancing the machine’s capacity for robust machining tasks.Spindle Taper

The spindle taper connects the spindle to the cutting tool and defines the tool-holding system. Common tapers like CAT, BT, HSK, and R8 each support different tool-holding configurations, affecting compatibility, stability, and performance.Spindle Bearings

Precision bearings support the spindle’s rotation, helping maintain stability and minimize vibrations. High-quality bearings are essential for machining accuracy, enabling smoother cuts and better surface finishes.Spindle Cooling

During high-speed operations, spindle cooling systems—such as air or liquid cooling—help dissipate heat, preserving accuracy and extending spindle life. Effective cooling prevents overheating, protecting both the spindle and the workpiece from potential damage.Additional Features

CNC spindles may come with automatic tool changers (ATCs), enabling quick and accurate tool swaps for enhanced productivity. This feature is particularly beneficial in automated environments, where reducing downtime is critical.

The CNC spindle is the core of a CNC machine, providing the rotational drive and stability needed for precise, efficient machining. Its speed, power, taper configuration, bearings, and cooling system all contribute to the machine’s overall performance and adaptability, making the spindle a pivotal component in achieving accuracy and productivity across a range of CNC applications.