Services Custom 4th-Axis for CNC

Custom 4th-Axis Module for CNC Router

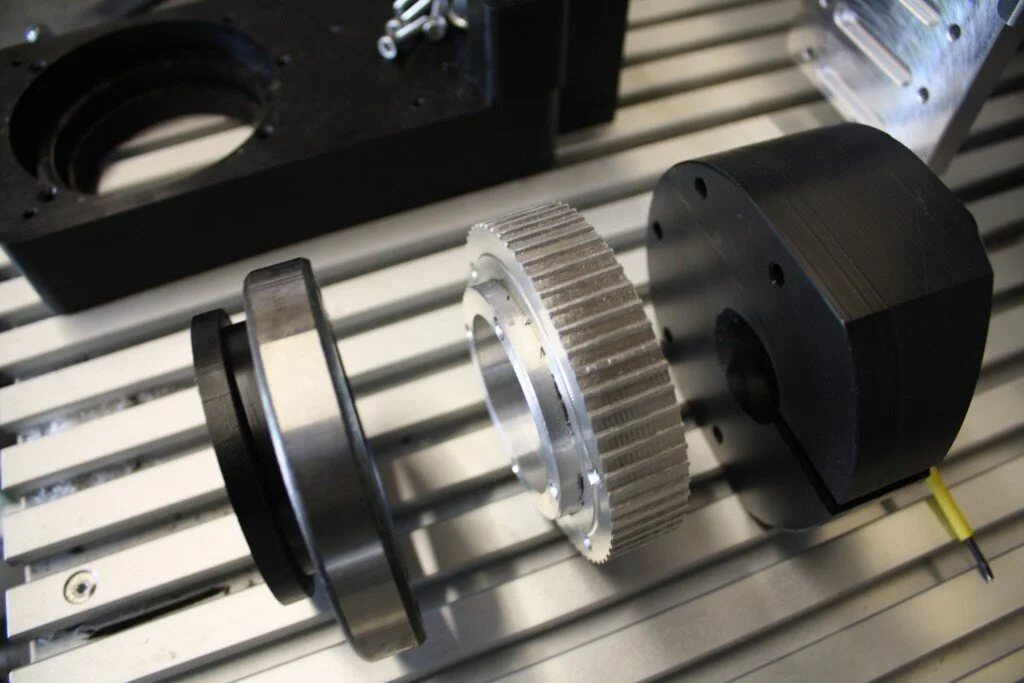

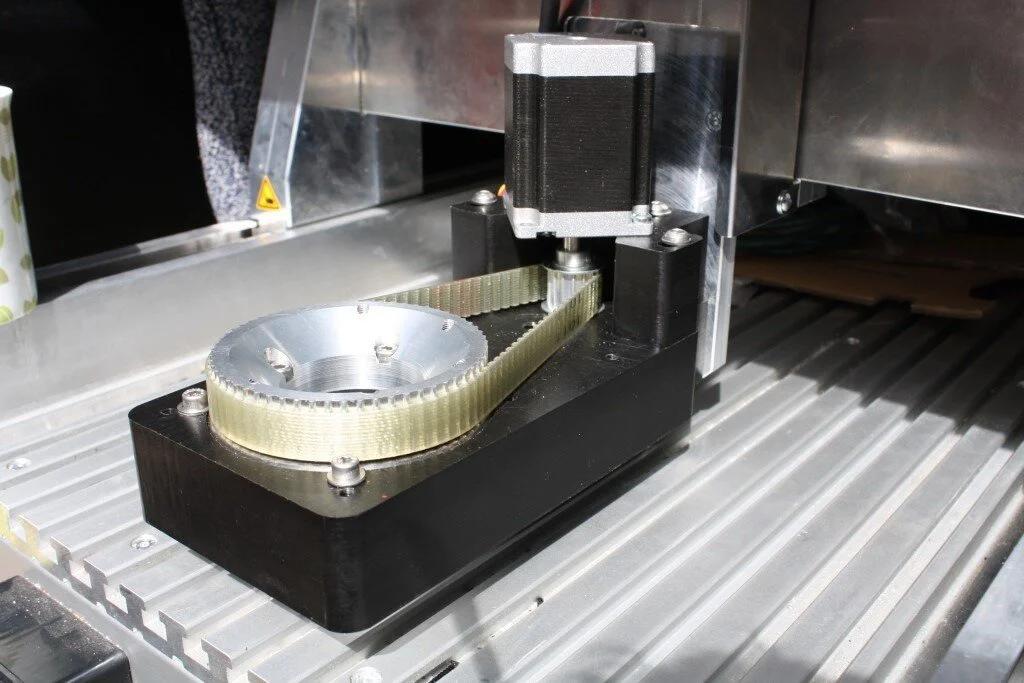

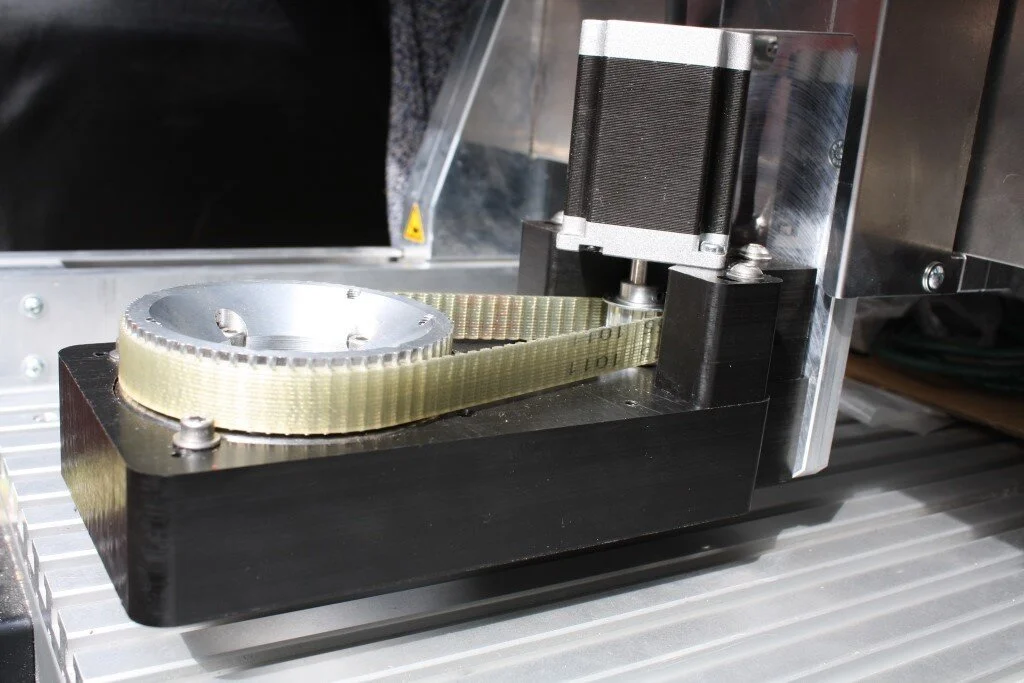

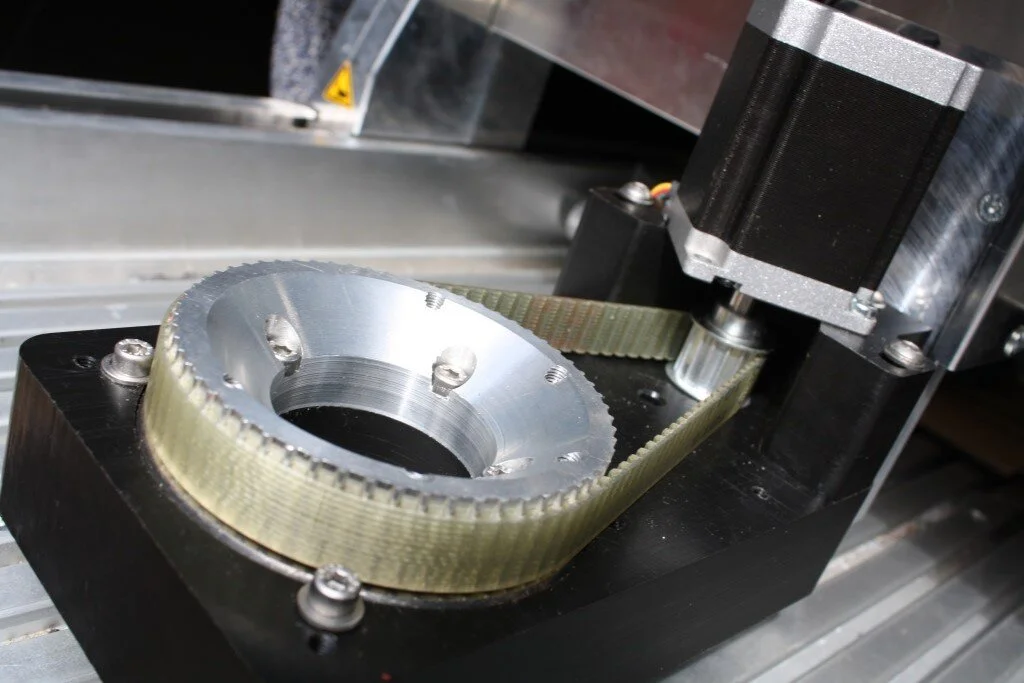

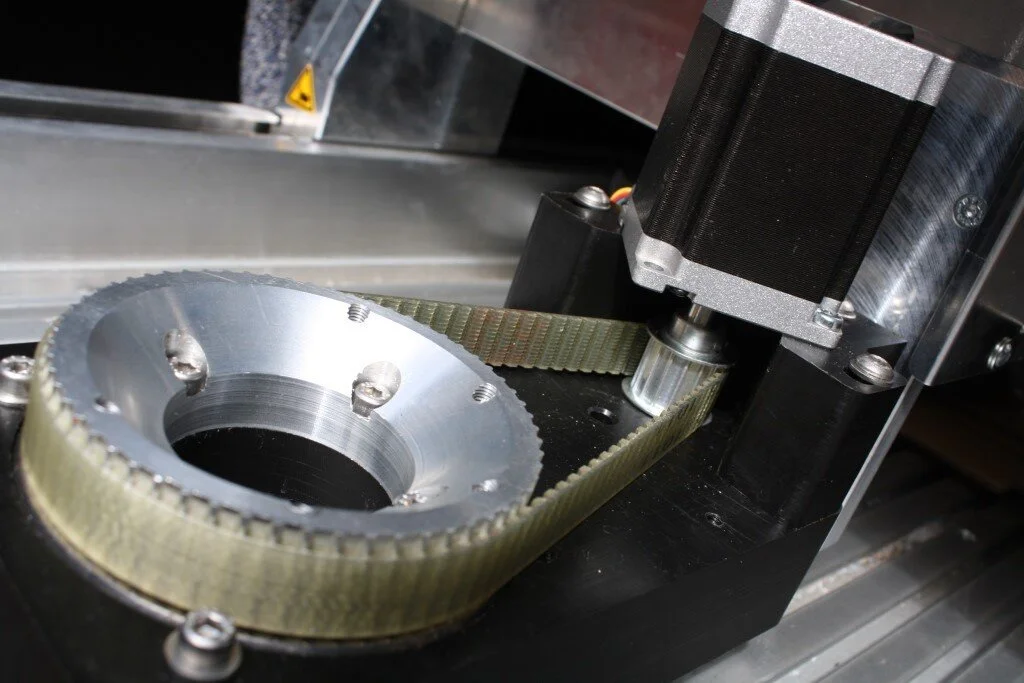

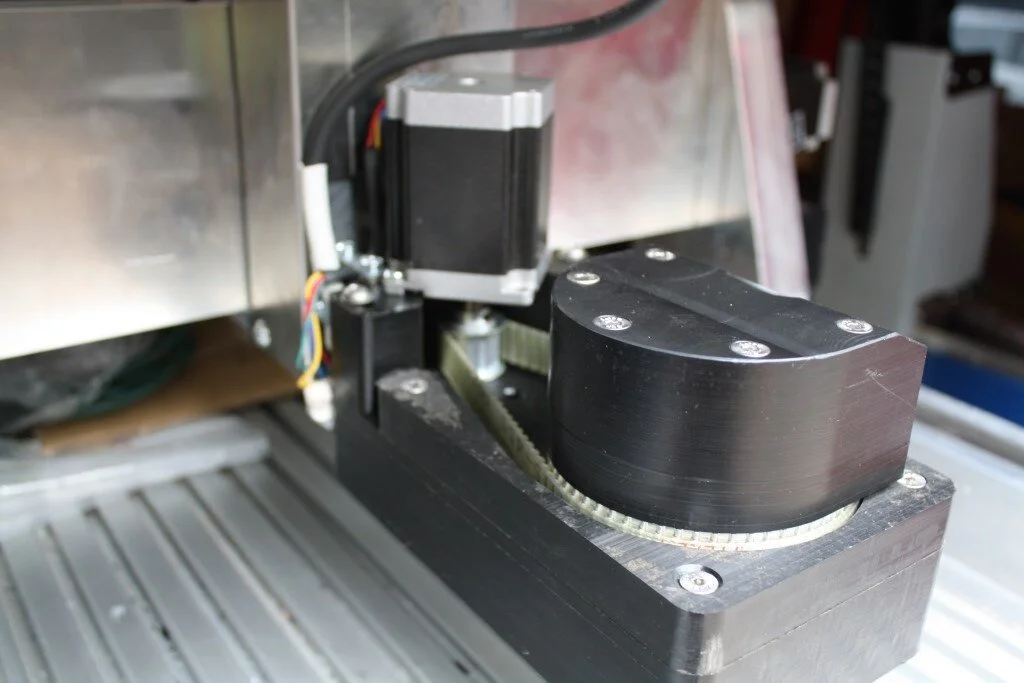

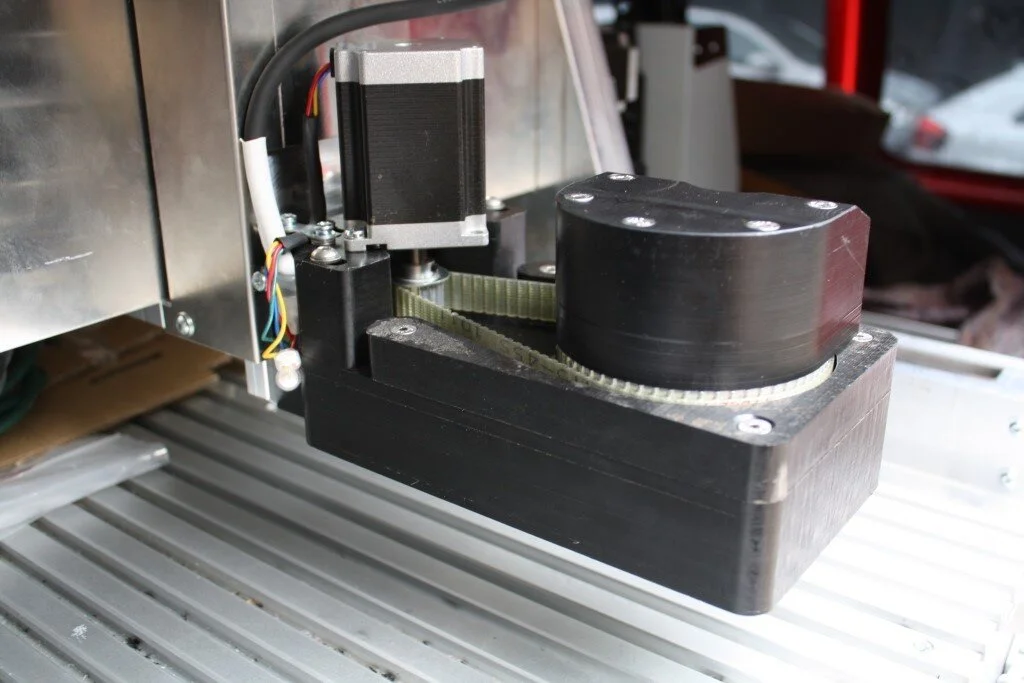

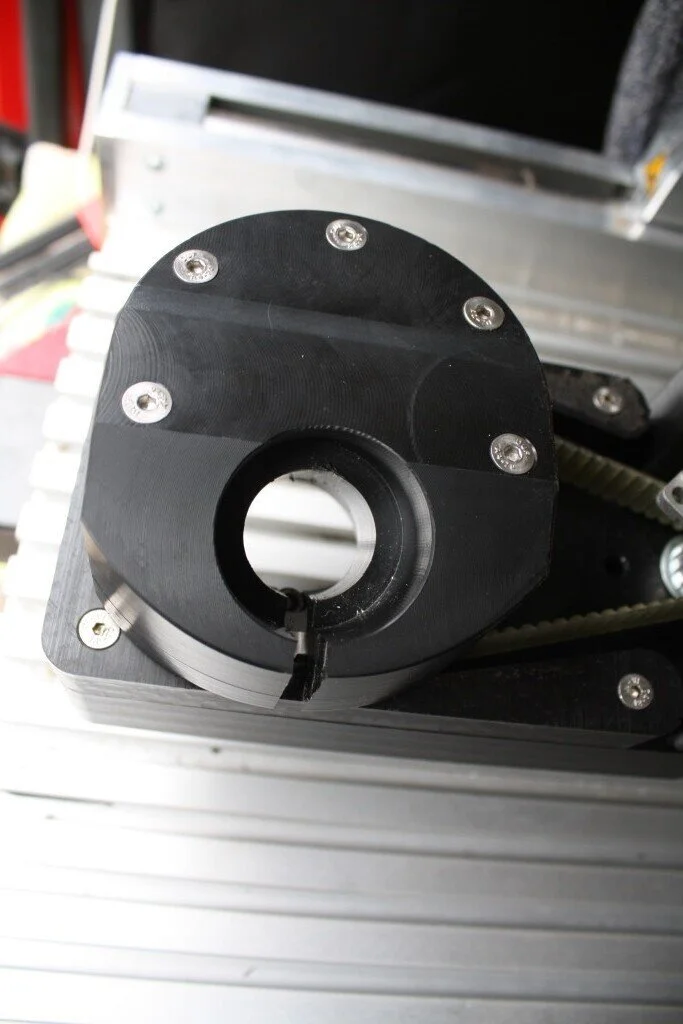

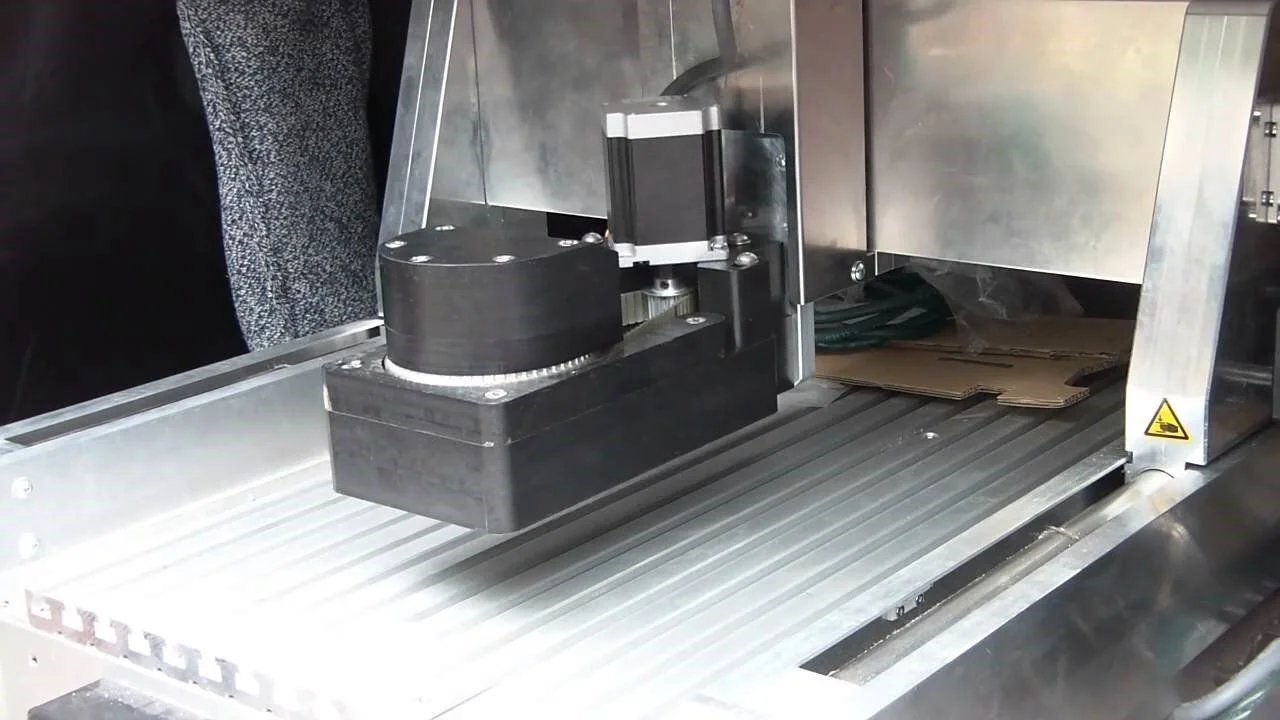

This project involved the design and commission of a cutting module that had to be both controlled for tangential cutting while being offset at an angle of 30 degrees off vertical. The system was designed around the CAD drawing of the cutting module provided by the customer.

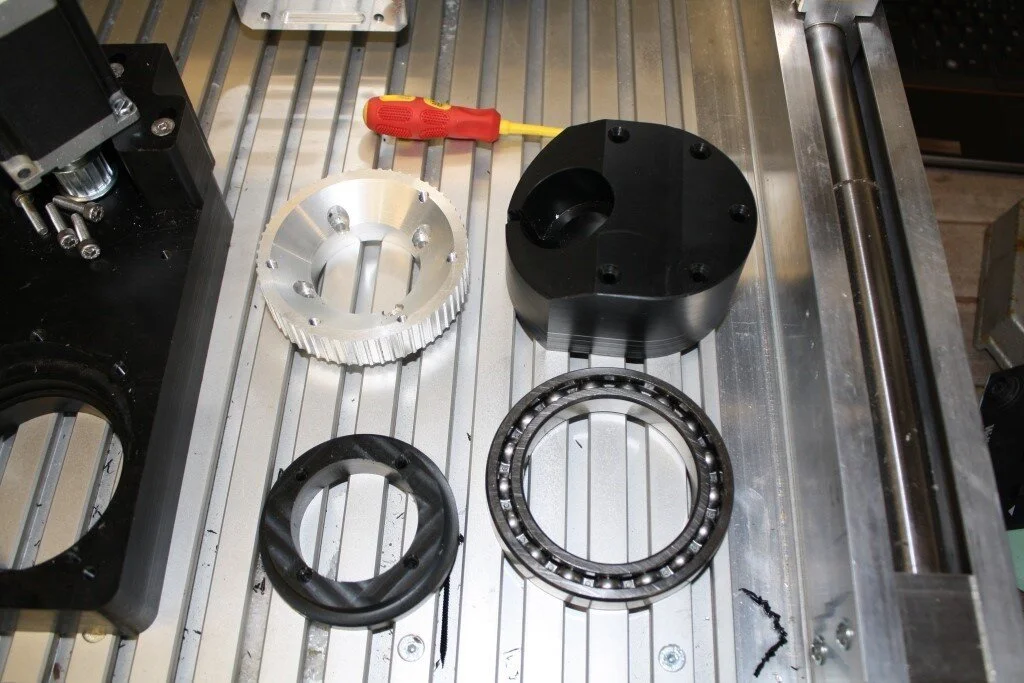

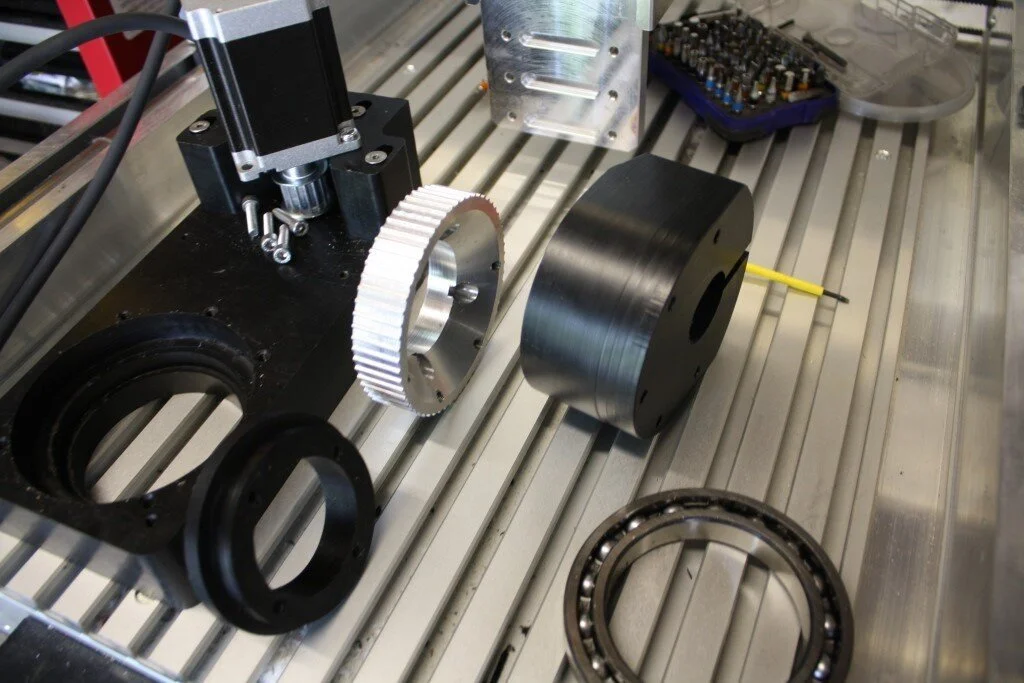

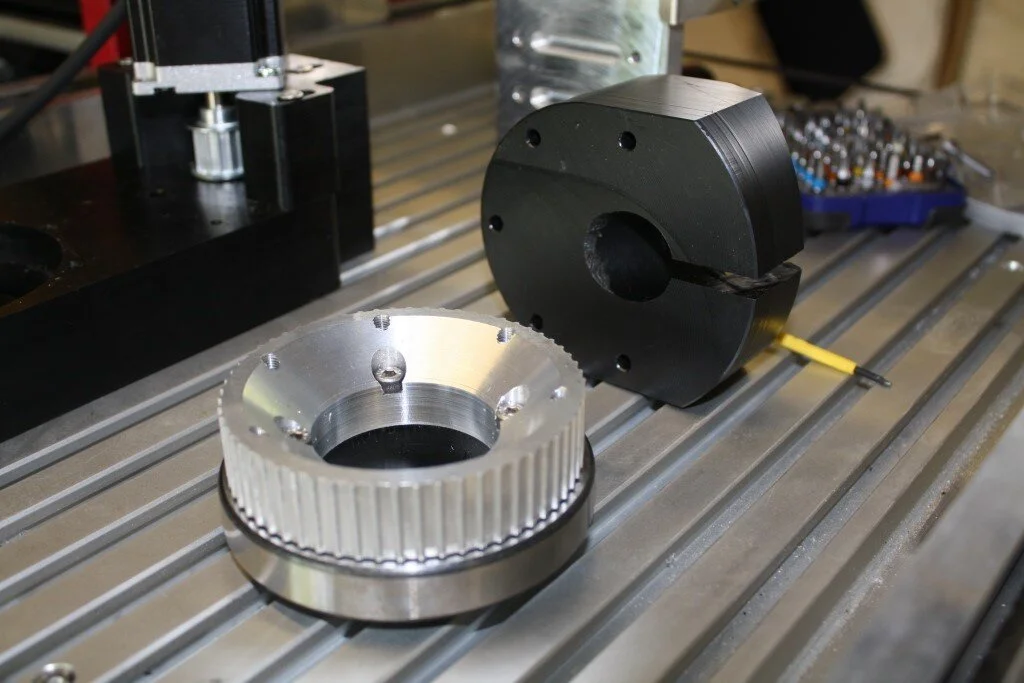

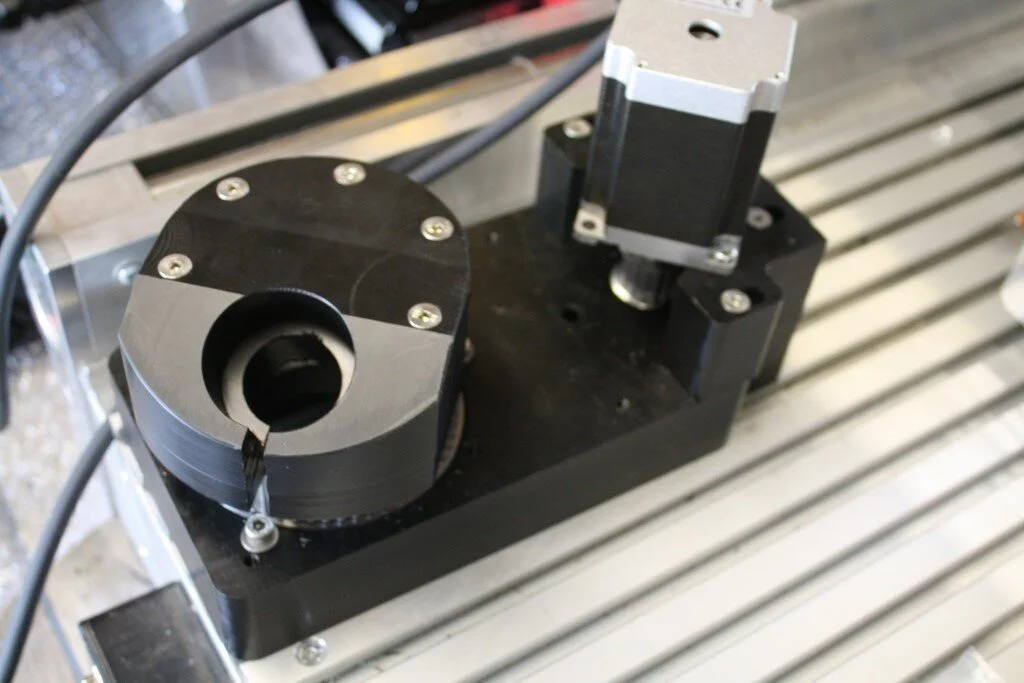

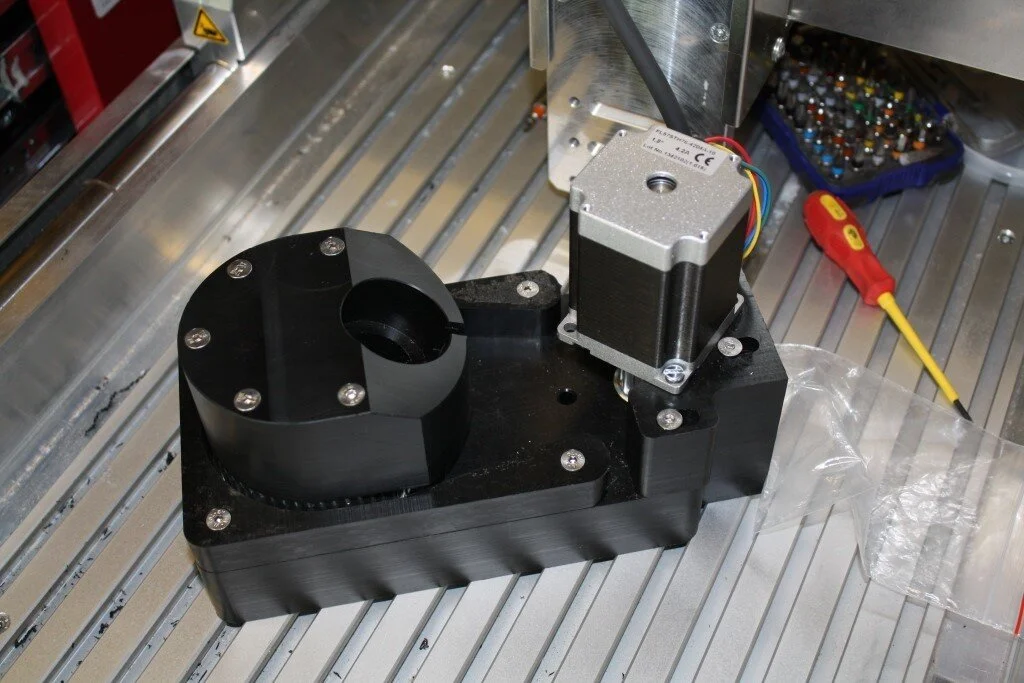

The fixture was designed using off-the-shelf pulleys and a belt. The main pulley was then modified to allow for the customer’s fixture to pass through the system at 30 degrees while retaining the ability to rotate the fixture in the 4th axis direction, as shown in the videos.

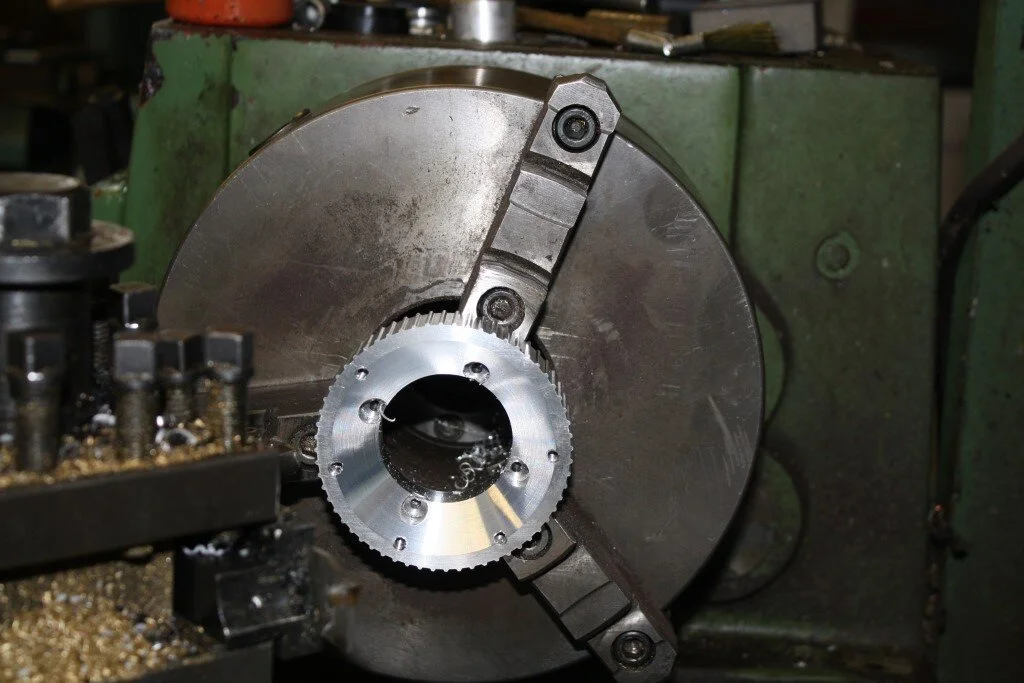

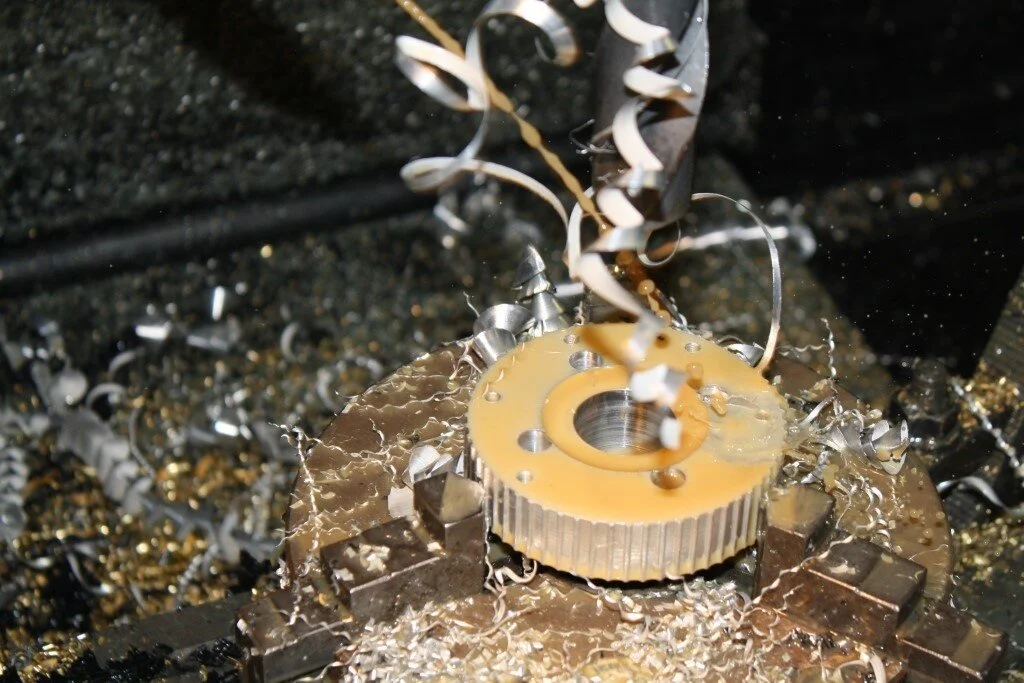

See below for some images from the part machining at JBEC

Custom 4th Axis Rotary Systems for CNC Machines

Stoney CNC designs and supplies custom 4th axis rotary systems for a wide range of CNC machines, enabling advanced machining capabilities such as indexing, rotary contouring and simultaneous multi-axis work. These systems allow for efficient production of parts that would otherwise require multiple setups, saving valuable time while increasing tool access and cutting flexibility.

Our 4th axis rotary units are built for integration with existing CNC milling systems, routers, or lathes, and can be tailored to fit a specific machine or table layout. We offer solutions with both manual and motorised rotary axis options, with spindle mount configurations and adaptable tooling interfaces.

These systems are ideal for:

Tube and pipe work

Complex profiles and circular slotting

Engraving on round parts

Multi-face machining operations

Our rotary systems are compatible with a wide range of CNC control software, and we can assist with both hardware setup and integration into your digital workflow. All systems are fully tested, calibrated and delivered ready to install.

If you’re looking to add a 4th axis to your current machining setup or need a bespoke system for a new application, our team can design and build a solution that meets your operational and spatial requirements.

Get in touch to discuss your custom 4th axis needs — whether it’s a single rotary table for a bench-top mill or a production-ready CNC machine upgrade with full servo control.