CNC Milling Spindle ⚙️⚙️⚙️

A CNC milling spindle is the primary rotating component of a CNC milling machine, driving the cutting tool to shape and cut materials with precision. Here are the key aspects of CNC milling spindles:

The CNC milling spindle is a critical component in CNC milling machines, directly impacting the quality and precision of the final product. The spindle is powered by a spindle motor, which enables high-speed rotation, essential for efficient material removal and fine finishes on the workpiece. Inside the spindle, precision bearings support the rotational stability, reducing vibration to ensure high accuracy during milling. Many CNC spindles are cooled using air or liquid systems to maintain performance at higher speeds, preventing overheating that could affect service life and quality. The spindle's collet holds cutting tools securely, allowing quick changes and accommodating various tool sizes, making it versatile for complex jobs. High-speed, high-quality spindles equipped with reliable motors and cooling systems provide the best results for manufacturers, ensuring consistent performance and extending the spindle’s service life.

Key Points about CNC Milling Spindles

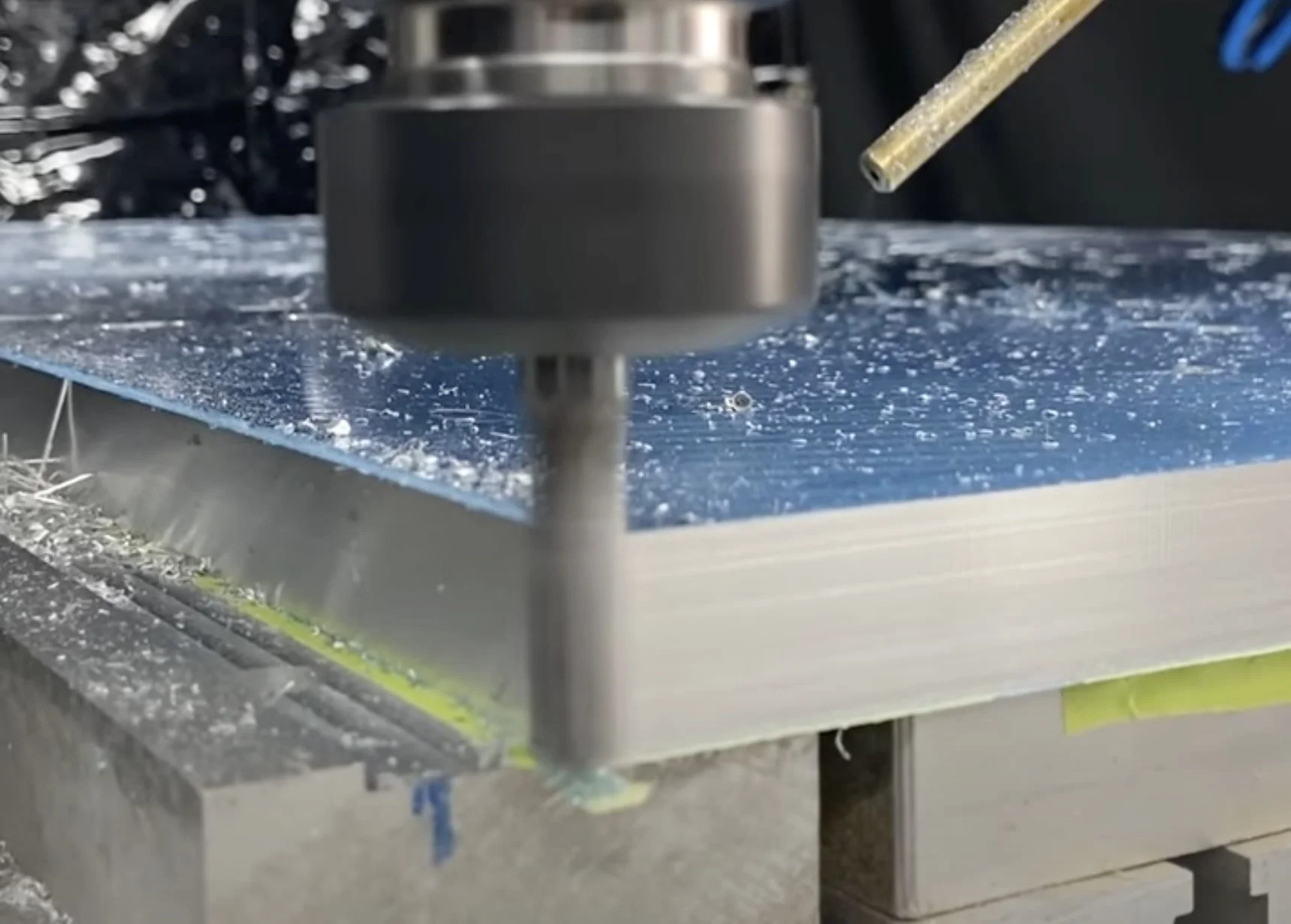

Video: CNC Machining Aluminium on a CNC Router from 5.0 Robotics - The Model 8

Function: The main role of a CNC milling spindle is to rotate the cutting tool at various speeds, enabling it to effectively cut and shape the material. The spindle's rotation is crucial for achieving the desired machining results.

CNC Control: Unlike manual milling machines, the spindle in a CNC machine is controlled by a computer. This control extends to the spindle's speed, direction, and depth of cut, allowing for precise, repeatable cuts and the creation of complex geometries that would be challenging or impossible to produce manually.

Design and Structure: CNC milling spindles are engineered to withstand heavy loads at high speeds. They typically feature a shaft that holds and rotates the cutting tool. Bearings support the shaft within the machine, ensuring smooth operation and minimizing vibration.

Speed: The spindle's rotational speed, measured in revolutions per minute (RPM), is a critical factor in the milling process. Adjusting the spindle speed according to the material and type of cut is essential for optimal machining performance.

Tool Holding: The spindle is designed to accommodate a variety of cutting tools, such as end mills, drill bits, and taps. These tools are secured in place by a tool holder or taper integrated into the spindle's design, ensuring stability and precision during operation.

Motor: The spindle is powered by a motor, which can either be directly integrated into the spindle or connected via a drive belt or gear system. This motor provides the necessary power to drive the spindle's rotation.

In summary, a CNC milling spindle is a vital component of a CNC milling machine, driving the cutting tool and enabling controlled, precise, and repeatable machining operations.