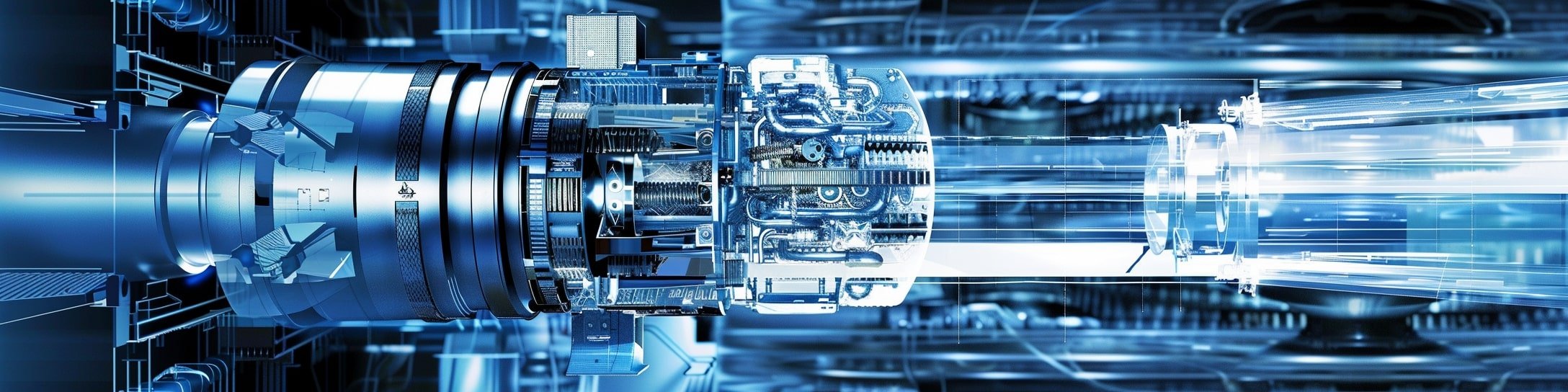

CNC Machine ⚙️

A CNC (Computer Numerical Control) machine is a computer-operated tool used in manufacturing to automate the movement and function of cutting tools, performing precise machining operations such as milling, turning, drilling, and cutting. CNC machines transform digital designs into physical parts by following programmed instructions, allowing for highly accurate, repeatable, and efficient production processes. This level of automation and control increases productivity, enhances quality, and reduces material waste compared to manual machining.

How CNC Machines Operate

CNC machines begin with a digital design, typically created in CAD (Computer-Aided Design) software. This design is then converted into machine-readable code, commonly G-code, by CAM (Computer-Aided Manufacturing) software. G-code provides step-by-step instructions for the CNC machine, directing cutting tool movements, spindle speeds, feed rates, and other parameters along multiple axes (e.g., X, Y, and Z) to execute complex machining operations.

Types of CNC Machines

CNC machines come in various types, each suited for specific applications:

CNC Mills: Use rotary cutting tools like end mills or face mills to remove material from a workpiece, creating intricate shapes and profiles.

CNC Lathes: Rotate the workpiece while a stationary cutting tool removes material, ideal for producing cylindrical or rounded parts.

CNC Routers: Primarily used for cutting, shaping, and engraving materials such as wood, plastic, and softer metals, commonly used in woodworking, sign-making, and prototyping.

CNC Plasma Cutters: Use a high-temperature plasma arc to cut through conductive metals like steel and aluminium.

CNC Laser Cutters: Employ a focused laser beam to cut, engrave, or mark a range of materials, including metal, plastic, and wood.

CNC Waterjet Cutters: Use a high-pressure water stream, often mixed with abrasives, to cut through materials without generating heat, suitable for delicate or heat-sensitive materials.

Advantages of CNC Machines

Precision and Accuracy: CNC machines produce parts with exact tolerances and high levels of precision.

Repeatability: These machines can consistently produce identical parts in high volumes, enhancing consistency.

Flexibility: CNC machines can easily accommodate design modifications or create custom parts on demand.

Reduced Waste: Optimized tool paths and controlled processes minimize material waste.

Lower Labor Costs: Automated operation reduces the need for manual oversight, lowering labour costs and minimizing human error.

Applications of CNC Machines

CNC machines are integral to industries like automotive, aerospace, electronics, and medical, where high-quality, precise components are essential. They are used to manufacture a wide range of parts and components from materials such as metal, plastic, wood, and composites, contributing to the production of everything from automotive parts and medical devices to electronic components and aerospace structures.

In summary, CNC machines represent a foundational technology in modern manufacturing, delivering precision, efficiency, and adaptability across diverse industrial applications.