CNC Router ⚙️

A CNC (Computer Numerical Control) router is a computer-controlled cutting machine used for precisely cutting, shaping, and engraving materials such as wood, plastic, composites, foam, and softer metals. CNC routers are widely employed in industries like woodworking, sign-making, prototyping, and furniture production, enabling users to create intricate designs, custom parts, and high-quality products with minimal manual effort.

How CNC Routers Work

CNC routers operate based on instructions from a digital design file created in CAD (Computer-Aided Design) software. The design file is converted into G-code through CAM (Computer-Aided Manufacturing) software, which provides specific, step-by-step instructions for the CNC router to follow. The G-code controls the movement of the cutting tool across multiple axes (typically X, Y, and Z) and manages variables such as spindle speed, feed rate, and cutting depth.

Key Components of a CNC Router

Gantry or Frame: The main structure that supports the spindle, cutting tools, and other components, allowing for movement along multiple axes.

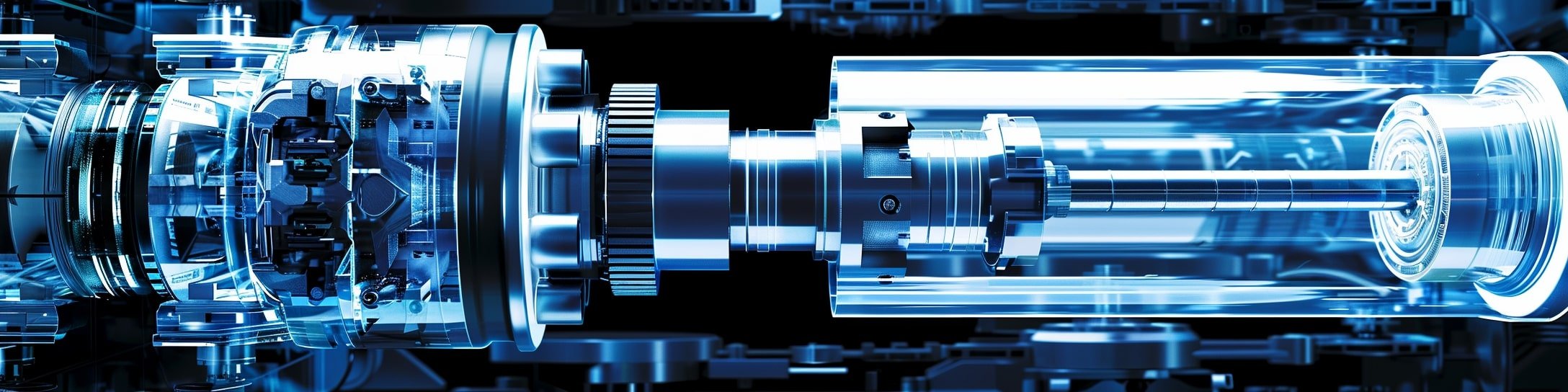

Spindle and Cutting Tool: The spindle holds the cutting tool (such as an end mill or router bit), which moves in various directions to precisely cut or shape the material.

Worktable: The surface that holds the workpiece in place, often equipped with clamps or a vacuum system to secure materials during machining.

Advantages of CNC Routers

Precision and Accuracy: CNC routers produce intricate, detailed cuts and engravings with high accuracy, ideal for complex designs and patterns.

Repeatability: CNC routers can create identical parts consistently across production runs, making them valuable for mass production and custom manufacturing.

Flexibility and Versatility: CNC routers can easily accommodate design adjustments, making them suitable for rapid prototyping, custom production, and small-batch runs.

Efficiency and Reduced Waste: The precise control over cutting paths minimizes material waste and optimizes material usage, lowering production costs.

Lower Labor Requirements: CNC routers operate with minimal human intervention, reducing the need for skilled labour and lowering operational costs.

Applications

CNC routers are essential tools in diverse applications, including:

Woodworking: Crafting cabinetry, furniture, doors, and decorative elements with precision.

Sign-Making: Cutting and engraving signage from wood, plastic, and composite materials.

Prototyping and Product Design: Creating prototypes and custom components with ease.

Custom Fabrication: Producing unique items for interior design, architecture, and decorative arts.

CNC routers are versatile, automated machines that provide precise, efficient, and repeatable machining for a wide range of materials. They offer significant advantages in productivity, accuracy, and flexibility, making them invaluable tools across industries such as woodworking, sign-making, and manufacturing. With their ability to handle complex designs and streamline production, CNC routers are essential for high-quality, cost-effective manufacturing.