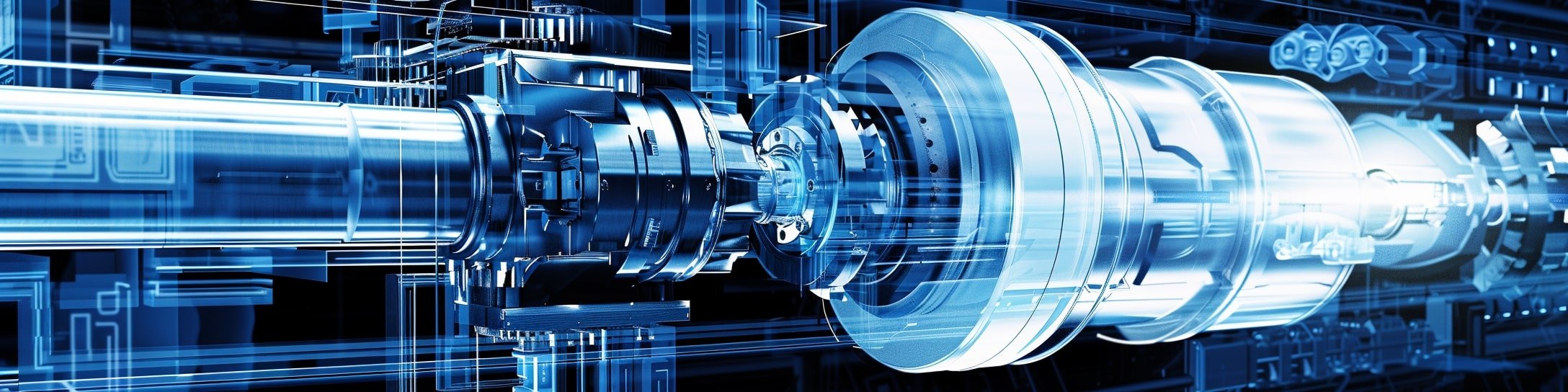

CNC Lathe ⚙️

A CNC (Computer Numerical Control) lathe is a precision machine tool that uses computer programming to control the movement of cutting tools, enabling the accurate shaping of workpieces. Unlike traditional lathes, CNC lathes rely on automated inputs, providing consistent and highly precise results. The defining feature of a lathe is that the workpiece rotates around an axis, while the cutting tools remain stationary or move along programmed paths.

Key Points About CNC Lathes

Function

The primary function of a CNC lathe is to remove material from a rotating workpiece to form a desired shape. CNC lathes are ideal for creating cylindrical, conical, or spherical shapes, and can perform a variety of operations, including turning, facing, drilling, reaming, and threading. Their versatility allows for the production of complex geometries.

Components

CNC lathes consist of several critical components:

Bed: The base of the machine that supports other components.

Headstock: Houses the spindle that holds and rotates the workpiece.

Tailstock: Supports the opposite end of the workpiece, especially for longer parts.

Carriage: Moves the cutting tool along the workpiece.

Tool Turret: Holds multiple cutting tools and automatically switches between them during operation, enabling complex machining processes.

Programming

CNC lathes are controlled using G-code, a programming language that specifies the tool's movement, speed, and cutting path. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is often used to generate G-code, translating a digital model of the part into precise instructions for the CNC lathe.

Benefits

Precision and Accuracy: CNC lathes offer high precision and repeatability, making them ideal for mass production where consistency is crucial.

Complex Machining: They can produce intricate shapes that would be challenging or impossible to create using manual lathes.

Increased Safety: Automation reduces the need for direct interaction with cutting tools, minimizing human error and enhancing safety.

Efficiency: CNC lathes can run continuously and quickly switch between tools, increasing productivity and reducing downtime.

Applications

CNC lathes are used across many industries, including automotive, aerospace, electronics, and general manufacturing. Common parts produced include screws, bolts, shafts, pulleys, wheel hubs, and intricate components for machinery and consumer products.

A CNC lathe is a highly automated, precision machine tool capable of creating a wide range of shapes and forms from rotating workpieces. With its ability to handle complex tasks, high precision, and efficiency, CNC lathes are essential in modern manufacturing for producing consistent, high-quality parts at scale.