Emil Nykvist, Biathlon ⚙️

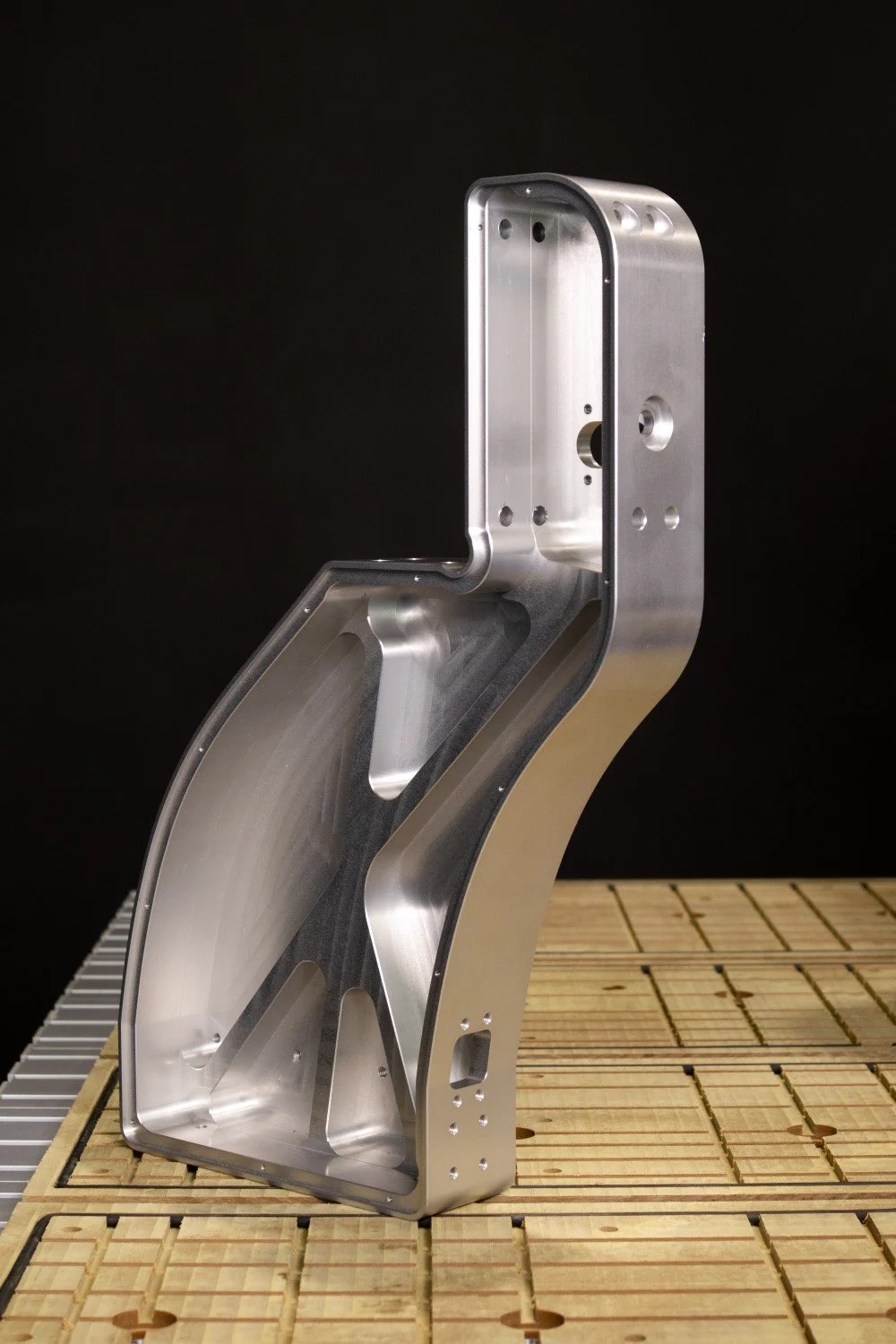

5.0 Robotics bringing CNC technology to the international sports application area! The rising star of Swedish biathlon, Emil Nykvist reached out to us after breaking his gun. With 5.0 Robotics industrial-grade machines, he was able to combine different parts of guns to make equipment that elevated his game for the competition.

Challenges can turn into advantages, especially if you have the mentality of a go-getter and find the perfect means to make things happen. We love supporting people who are bold and creative enough to take control in their hands, no matter the industry they operate in.

Video

Video: 5.0 Robotics CNC Router Machining Olympic Gun in 4 Hours

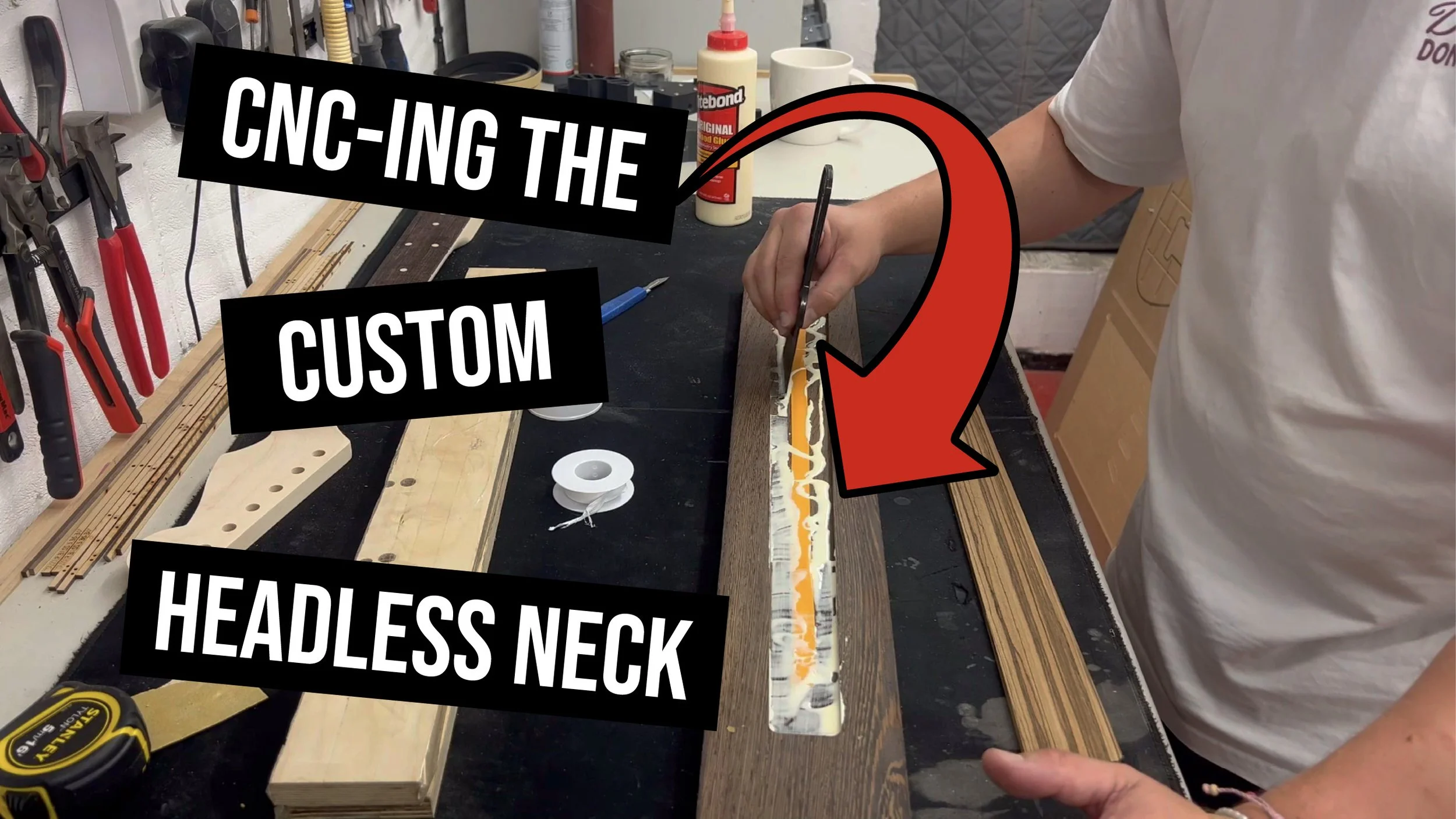

This video features biathlete Emil Nykvist, who collaborated with 5.0 robotics to craft a custom biathlon gun using a CNC machine.

The video opens with Emil introducing 5.0 robotics, a company specializing in producing industrial-grade machines in a compact format. Emil then explains how he conceived the idea of creating a personalized gun. He had been competing for eight years and had used various guns, but none of them felt perfect. He noticed his friend Jasper had a particularly impressive gun, and it dawned on him that a hybrid of the two guns would be ideal.

Emil and Jasper scanned their respective guns and then utilized Fusion software to merge the desirable features of each gun into a single design. Subsequently, they collaborated with Pate to employ a CNC machine to bring this new gun to life. The first two components of the gun turned out exceptionally well, and Emil was ecstatic about the final product. He describes the gun as lightweight, compact, and comfortable to grip. He confidently asserts that it is one of the finest guns in the world.

In the concluding part of the video, Emil reflects on his biathlon journey. He has participated in numerous World Championships and European Cups and recently qualified for the World Cup in Lofer. Emil expresses great pride in being among the top biathletes in Sweden and eagerly anticipates competing in the World Cup.

5.0 Robotics ATC Model 8 Cooling Extraction and ATC

Fully automated tool changing

Hardwood Rosette milled on the Model 8

Detailed 3D milling of hardwood rosette on the model 8

5.0 Robotics Upstand Manufacture

Upstands made from solid alloy to maximise stiffness.

5.0 Robotics Model 8 milling Carbon Fibre

2mm drone bodies made out of 2mm carbon fibre,

PR-Studios millig chamfers using a high end vice

A very good demonstration of a vice going quickly onto the bed of the Modle 8 from 5.0 robotics.

Model 8 milling some exquisite work on a Tamar 7

This is an excellent demonstration of the vacuum table and large Z axis stroke allowing the table, fixture, stock and cutter process the full body in 2 operations.

Model 8 milling some exquisite work on a Custom Tamar.

Take note of the vacuum work holding in use in this video. The guys making full use of the Model 8 work area.

Model 8 QTC (Quick Tool Change) Intro Video

A very good into into the QTC (Quick Tool Change) spindle system and what its advantages are vs the typical MTC(Manual tool change) spindle.

Model 8 milling 3mm aluminium usig the tape and goue method

These parts were needed ASAP for a client and the tape and glue method was used to secure the 3mm stock .

Model 8 milling 6mm aluminium into a new bracket

This bracket is used as a stopping mechanism on a CR PLASMA Engracving system to keep the head up when not being used

Model 8 milling 30mm aluminium into a custom fixture

This fixture was used to locate clients parts for a repetitive production application. We supplied the machine fully programmed and ready to produce.

Model 8 milling high end hardwood furniture

Petter over at NORDICUT doing a great job making some very high end furniture on the Model 8 Executive.

Model 8 milling 30mm aluminium into a custom fixture

This fixture was used to locate clients parts for a repetitive production application. We supplied the machine fully programmed and ready to produce.

Check out the Model 8 ATC

The Model 8 can be supplied with an ISO30 ATC running on 220V AC domestic supply. Running a 9 Tool Magazine.

StoneyCNC Model 8 Exec Automation Cell

StoneyCNC developed a unique parallel processing cell to allow operators to load product while the machine was also at the same time - machining product.

James Yarde - Yarde Guitars

Check out James creating some impressive hardwood guitar body work on his Executive 8 from 5.0 Robotics

Check out Pieters work at Blue Ocean Designs.

The Model 8 Executive from 5.0 Robotics is used to mill out a carbon fibre mould from a block of 250 x 500mm x 100mm EP-700 epoxy board.

Explore how a custom bicycle maker uses CNC machining to craft high-quality carbon fiber components, from handlebars to complete bikes, with precision.

Swedish biathlete Emil Nykvist used 5.0 Robotics CNC technology to craft a custom biathlon gun, enhancing his performance for competition.