5-Axis CNC

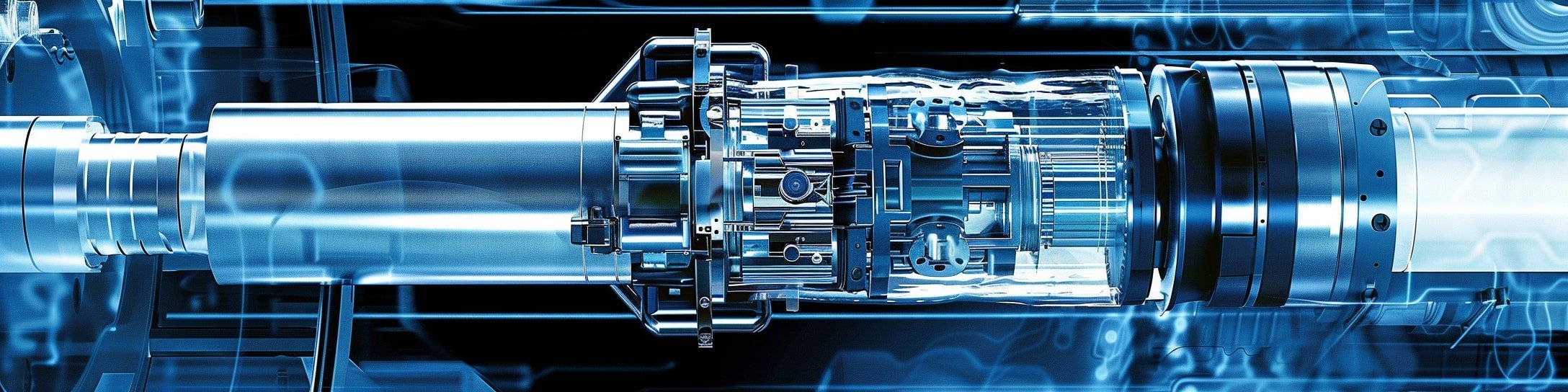

A 5-axis CNC (Computer Numerical Control) machine is a sophisticated CNC machine that operates on five different axes, adding two rotary axes to the standard X, Y, and Z linear movements. These additional rotary axes, often labelled A, B, or C, enable the machine to tilt and rotate both the cutting tool and the workpiece, enhancing flexibility and precision during machining.

5-Axis CNC machines are the pinnacle of milling technology, offering unparalleled accuracy and efficiency in the production of complex parts. These machines offer advanced automation, enabling simultaneous movement along five axes, reducing setup time and enhancing precision. Ideal for industries requiring intricate designs, 5-axis CNC machines deliver high-quality products that meet exacting customer specifications. With their ability to handle a wide series of operations in a single setup, they provide excellent value for high-mix, low-volume manufacturing. Manufacturers benefit from dedicated support and after-sales service to maximise machine performance. This cutting-edge technology empowers businesses to stay competitive by delivering superior quality and reduced production times.

Key Features of 5-Axis CNC

Enhanced Machining Capabilities

The two extra axes allow 5-axis CNC machines to create complex shapes and intricate features that would be difficult or impossible to achieve with 3-axis or 4-axis machines. This capability is particularly valuable for parts with curved surfaces, undercuts, or detailed geometries.

Faster and More Efficient Machining

By allowing simultaneous manipulation of the cutting tool and workpiece, 5-axis CNC machines can significantly reduce machining time, improve surface finishes, and decrease the need for multiple setups. This results in higher productivity and better quality parts.

Applications

5-axis CNC machines are used in industries such as aerospace, automotive, medical device manufacturing, mould-making, and woodworking. They are ideal for creating high-precision components like turbine blades, medical implants, and complex mould patterns.

Types of 5-Axis CNC Configurations

Indexed 5-Axis CNC

The rotary axes adjust the workpiece to specific angles and lock it in place for 3-axis machining. This setup is useful for parts that require precise angular machining across multiple sides.Continuous 5-Axis CNC

The rotary axes remain in motion throughout the cutting process, enabling the cutting tool to continuously follow complex paths. This setup is ideal for creating smooth, contoured surfaces and intricate features, such as parts with negative drafts or undercuts.

Software for 5-Axis CNC

Operating a 5-axis CNC machine requires specialised software that can create advanced toolpaths and manage the machine’s movements. Programs like Mastercam, Fusion 360, and SolidCAM are commonly used for 5-axis programming, translating digital models into precise machining instructions.

A 5-axis CNC machine offers unparalleled precision, flexibility, and efficiency, making it the go-to solution for industries requiring complex shapes and high-quality finishes. Its ability to operate on five axes enables it to produce intricate parts with minimal setup, ensuring faster, more accurate machining.