4-Axis CNC Router

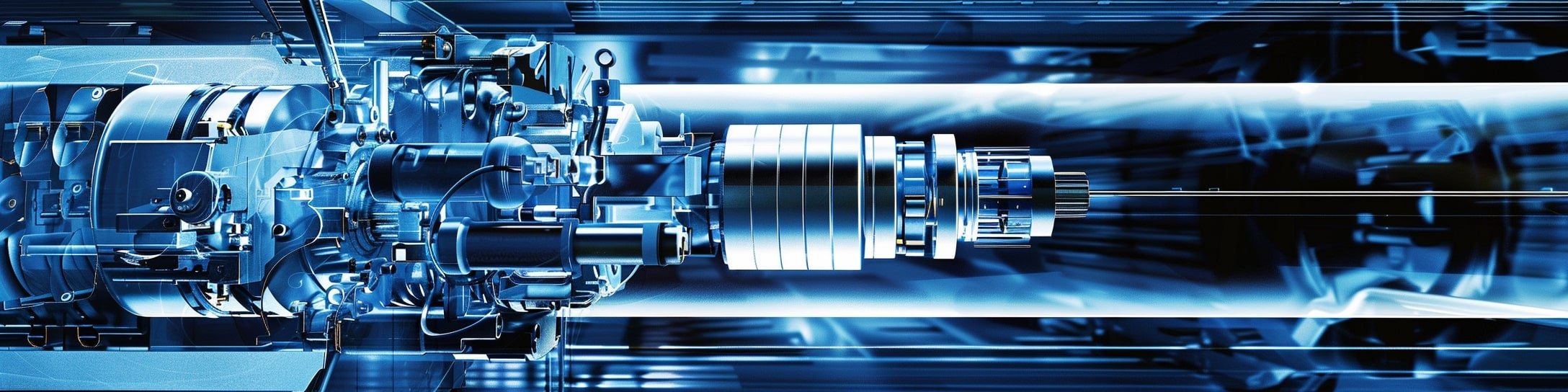

A 4-axis CNC router is an advanced CNC (Computer Numerical Control) machine with an additional rotary axis, known as the A-axis, which complements the standard X, Y, and Z axes of a 3-axis router. This extra axis allows the workpiece to rotate during machining, enabling more intricate operations and complex cuts that aren’t possible on a traditional 3-axis CNC router.

A 4-axis CNC router is an advanced CNC machine designed to handle more complex cutting tasks by enabling rotational movement around one axis in addition to the traditional linear X, Y, and Z axes. This added capability allows CNC machines to produce intricate parts with precision, such as cylindrical objects or designs that require carving on multiple sides. Equipped with specialised tools and tooling, a 4-axis router is ideal for manufacturing decorative woodwork, custom moulds, or precision-engineered parts. It is considered one of the best solutions for applications that require additional flexibility and detail, providing enhanced efficiency and quality in a single CNC machine.

Key Features of 4-Axis CNC Routers

Enhanced Machining Capabilities

The additional A-axis on a 4-axis CNC router enables machining curved or angled surfaces, detailed patterns, 3D relief carvings, and cylindrical parts. Continuous rotation capability can yield smoother finishes, shorter machining times, and fewer setup adjustments.

Applications

4-axis CNC routers are widely used in woodworking, sign making, furniture production, mould making, and various manufacturing fields. They are compatible with a wide range of materials, including wood, plastics, foam, and soft metals like aluminium.

Configurations of 4-Axis CNC Routers

Indexed 4-Axis CNC Router

In an indexed configuration, the rotary axis positions the workpiece at specific angles and locks it in place for machining using the standard 3-axis movement. The rotary axis repositions the workpiece between cuts, making this setup ideal for parts with multiple sides or features that need precise angular positioning.Continuous 4-Axis CNC Router

In a continuous setup, the rotary axis remains in motion, allowing the cutting tool to follow complex, curved paths continuously. This configuration is ideal for creating intricate shapes and sculpted surfaces, making it popular for 3D carvings and contoured parts.

Software Requirements

Operating a 4-axis CNC router requires specialised CAD/CAM software to create precise tool paths and control movements. Programs like VCarve Pro, Fusion 360, and Aspire support 4-axis functionality, allowing users to design complex models and generate accurate G-code for machining.

A 4-axis CNC router offers greater flexibility and efficiency than traditional 3-axis routers, enabling it to handle more detailed and complex projects. Its rotary axis makes it an ideal choice for industries requiring high-quality finishes on intricate shapes, expanding the range of applications achievable with CNC technology.