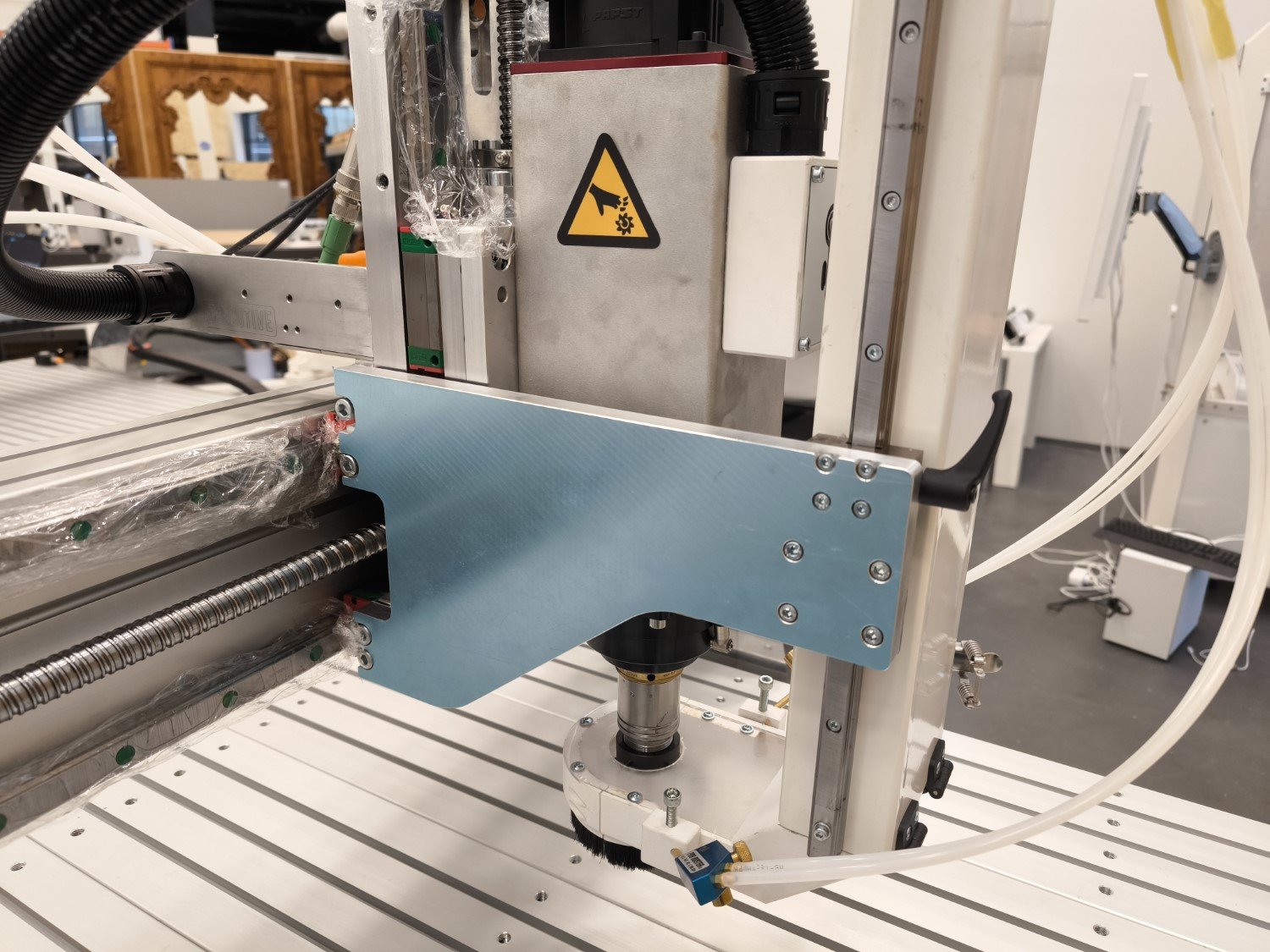

5.0 Robotics integrated fogbuster cooling and spray system

Fogbuster cooling and spray system

Advantages

Efficiently cools the cutting zone to prevent heat-related issues (e.g., melting or tool damage).

Uses air mist for effective chip evacuation and clean machining.

Enhances surface finish and tool life with optional cutting fluid.

Fog Buster Spray Cooling System

The Fog Buster spray cooling system addresses common challenges in machining materials like aluminum and plastics. It excels in the following ways:

Temperature Control: Prevents heat buildup at the cutting zone, which is critical when working with heat-sensitive materials like acrylic. Without proper cooling, the acrylic can melt, stick to the tool, and damage the machined surface.

Chip Evacuation: Uses an air blast or air mist to remove chips from the cutting zone, preventing recutting and maintaining clean operations. This feature is particularly useful in aluminum machining.

Enhanced Surface Finish: Incorporating alcohol-based or synthetic cutting fluid into the spray improves surface finish and extends tool life, providing optimal results.