5.0 Robotics Custom Fixturing

5.0 Robotics Custom Fixturing

Advantages:

Enhances efficiency and precision for specialized operations.

Reduces setup time and errors in high-volume production.

Supports process automation with tailored solutions.

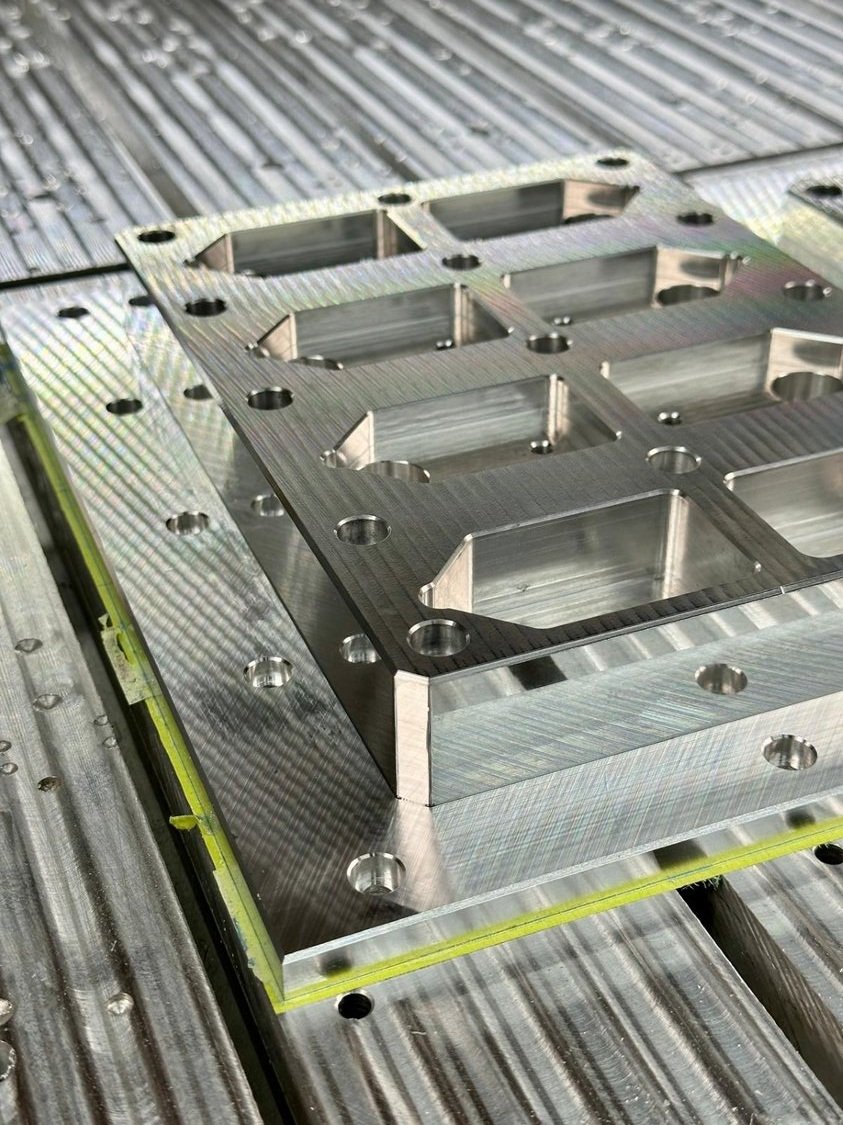

Custom Fixturing Systems:

Purpose: Provide specialized solutions for securing workpieces during machining, tailored to specific applications and needs.

Standard Aluminum T-Slot Table:

Comes as standard with the Model 8 Executive series.

Offers high versatility for clamping various workpieces.

Custom Fixtures:

Designed for specific components or products.

Features include:

Toe clamps or Pit Bull clamps for secure holding.

"Go/No-Go" geometries to ensure correct placement of parts.

Clearly labeled parts and locations for easy setup.

Ideal for high-volume, repetitive work where precision and standardization are critical.

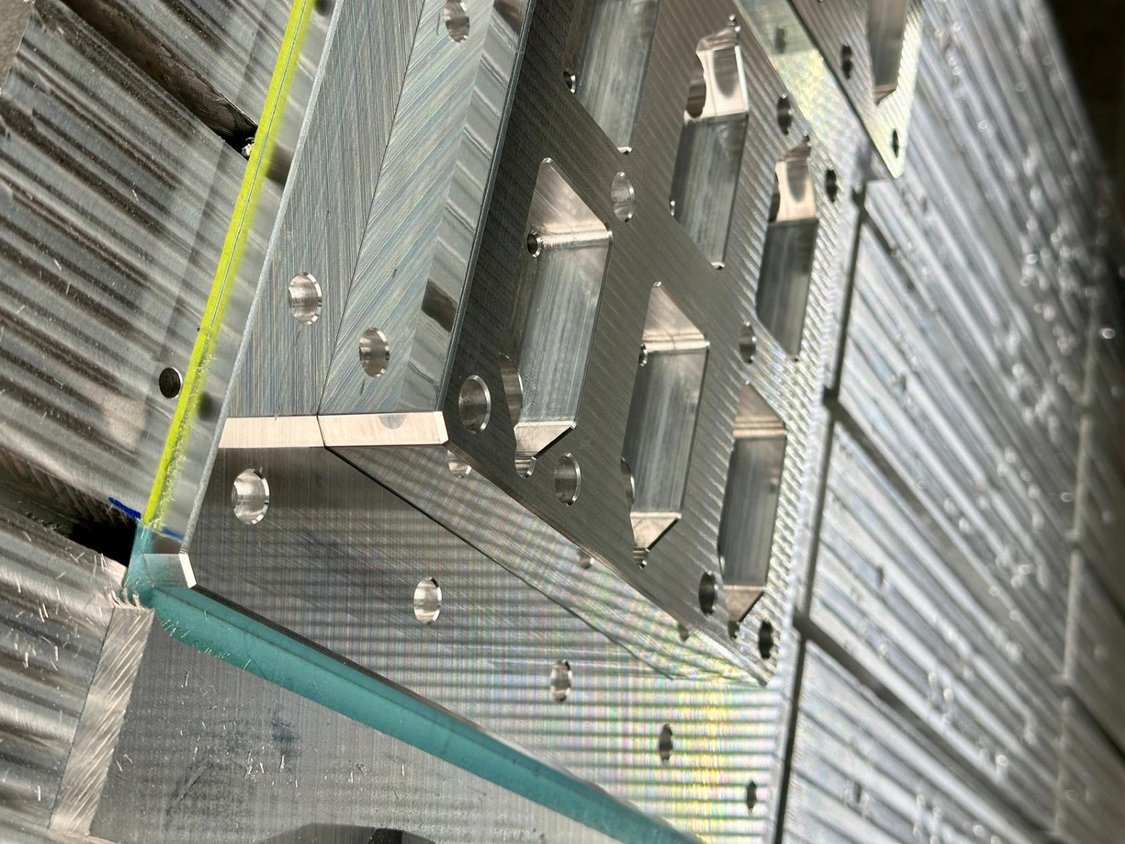

Sub-Fixturing Systems:

Provides flexibility while maintaining standardization.

Includes:

Common X-Y positions.

Slots and locating pins for adjustable configurations within certain part sizes.

Helps streamline and refine the machining process for variable part requirements.

Manufacturing Process:

Custom fixtures and sub-fixtures are designed and machined directly on the CNC machine itself.

Ensures perfect alignment and compatibility.

Advantages:

Enhances efficiency and precision for specialized operations.

Reduces setup time and errors in high-volume production.

Supports process automation with tailored solutions.

Customization Service:

If you have specific needs or challenges, a consultation is available to assess your requirements and design the most effective solution.