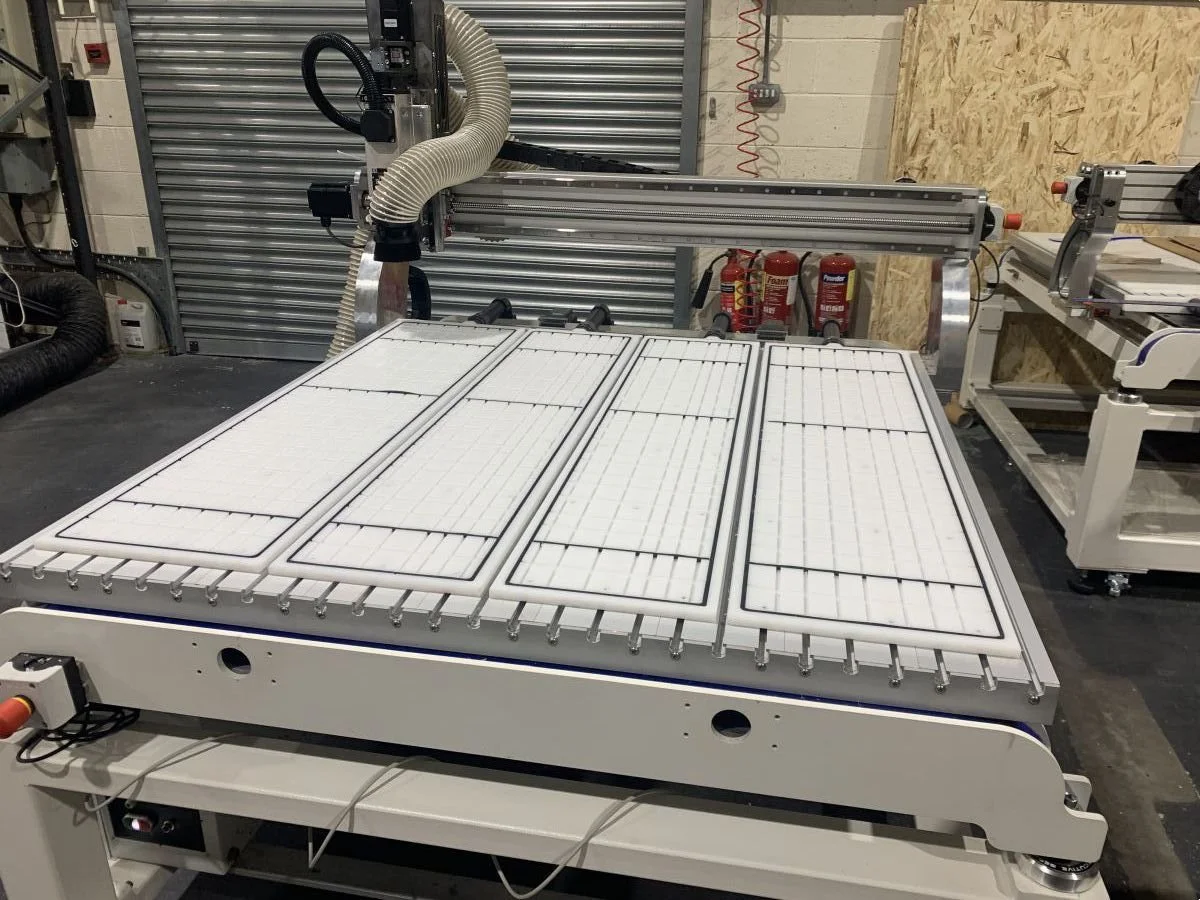

50 Robotics Vacuum Table System

50 Robotics Vacuum Table System

Advantages:

Highly efficient for large-scale sheet material processing.

Facilitates clean cuts without holding tabs, leaving parts ready for sanding.

Offers flexibility for creating specialized vacuum setups for custom applications.

Vacuum Table (Suction Table or Vacuum Chuck)

Purpose: Provides a secure and flat work surface using vacuum pressure, eliminating the need for physical clamping.

Key Features:

Bolted to the machine bed and connected to a vacuum pump system.

Ideal for machining sheet materials like acrylic, aluminum, plywood, and MDF.

Uses a sacrificial MDF layer that is surfaced flat to ensure precision machining.

Supports both large sheet work and custom vacuum fixtures, such as for guitar bodies and necks.

Maintains versatility with access to T-slot channels for manual clamping when needed.

Compatible with additional adhesive-based methods (e.g., 3M red-capped photo mount spray) for enhanced small-part machining.

Specifications:

Available for Model 8, Model 16, and Model 32 systems.

Various pump options: Single-phase or three-phase, with power ranging from 2.2 kW to 5.5 kW.

Advantages:

Highly efficient for large-scale sheet material processing.

Facilitates clean cuts without holding tabs, leaving parts ready for sanding.

Offers flexibility for creating specialized vacuum setups for custom applications.