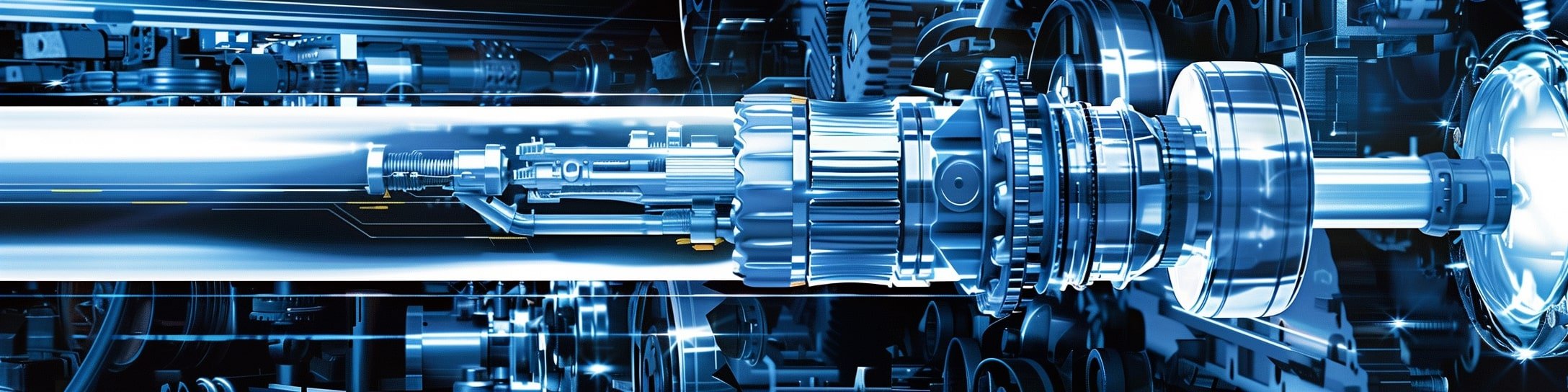

Swiss Lathe

A Swiss lathe, also known as a Swiss-type lathe or Swiss screw machine, is a precision lathe designed for machining small, complex parts with high accuracy and repeatability. Unlike conventional lathes, a Swiss lathe uses a sliding headstock and a guide bushing to support the workpiece close to the cutting tool, allowing for high precision, especially on slender and delicate parts.

Key Features of a Swiss Lathe

Sliding Headstock

The headstock on a Swiss lathe moves longitudinally, feeding the workpiece through a guide bushing. This minimises deflection, providing stability and support for long, slender parts.Guide Bushing

The guide bushing holds the workpiece firmly as it is fed through the machine, keeping it close to the cutting tool. This setup allows for precise cuts with minimal vibration, even on small diameters.Multiple Tooling Stations

Swiss lathes are equipped with multiple tools and can perform simultaneous operations, turning, drilling, threading, and milling, boosting productivity and reducing cycle time.Automatic Bar Feeding

Swiss lathes often have bar feeders that continuously feed material into the machine, making them highly suitable for high-volume production runs.

Advantages of Swiss Lathes

High Precision and Repeatability

The design of a Swiss lathe minimises deflection and vibration, enabling very tight tolerances and making it ideal for intricate, precision parts.Efficient Production

Capable of performing multiple operations in a single setup, Swiss lathes streamline the production process, reducing the need for secondary operations.Long, Thin Parts

The guide bushing and sliding headstock allow Swiss lathes to effectively machine long, thin, or slender parts without bending or warping.

Applications of Swiss Lathes

Medical Devices … used to create small, precise components like bone screws and implants.

Aerospace … ideal for small, detailed parts with strict tolerance requirements.

Electronics and Connectors … often used to produce components for connectors, switches, and other small electronic parts.

Watchmaking and Jewellery … widely used in the production of fine, detailed watch components and jewellery pieces.

A Swiss lathe is a specialised precision machine designed for producing small, complex, and often long parts with high accuracy. By using a sliding headstock and guide bushing, Swiss lathes maintain stability and control over the workpiece, making them ideal for high-precision applications across industries such as medical, aerospace, electronics, and horology.