JBEC Professional CNC Routers Model 1259012

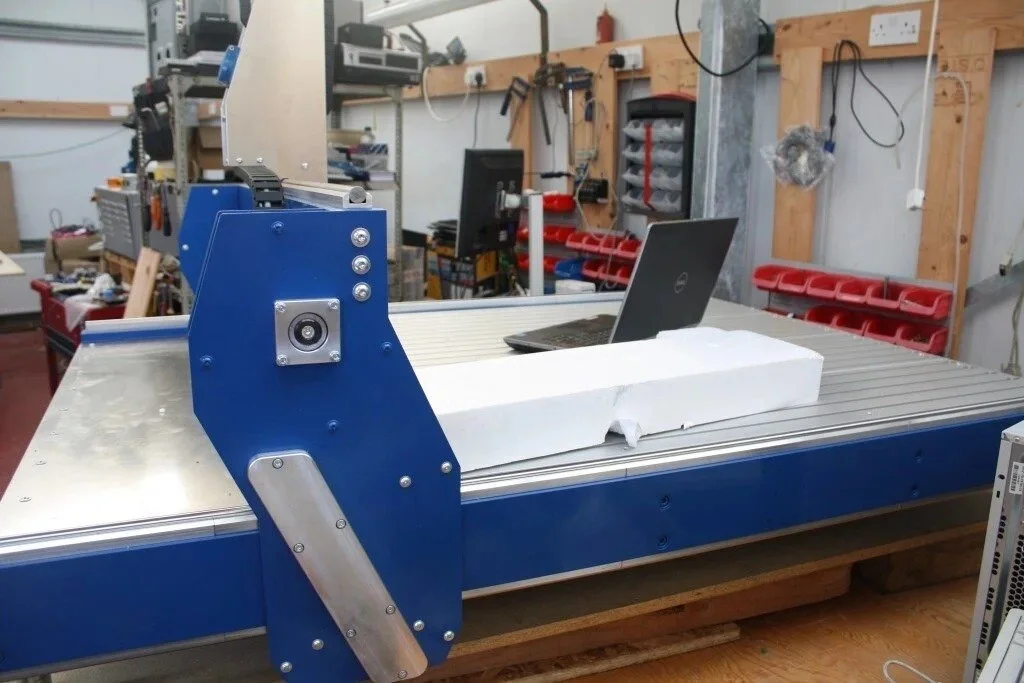

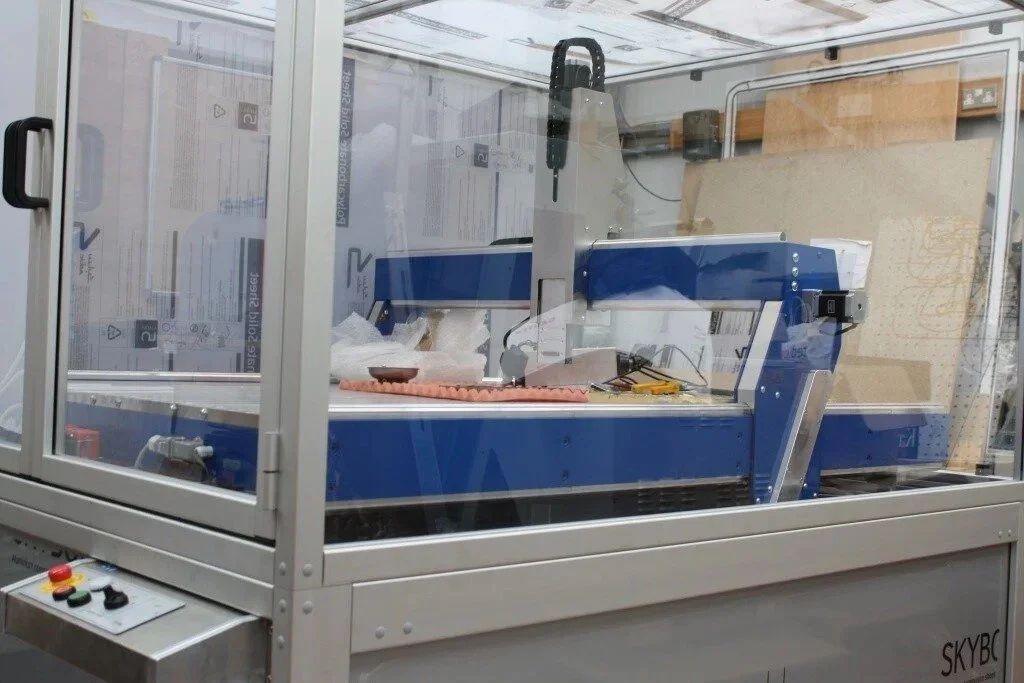

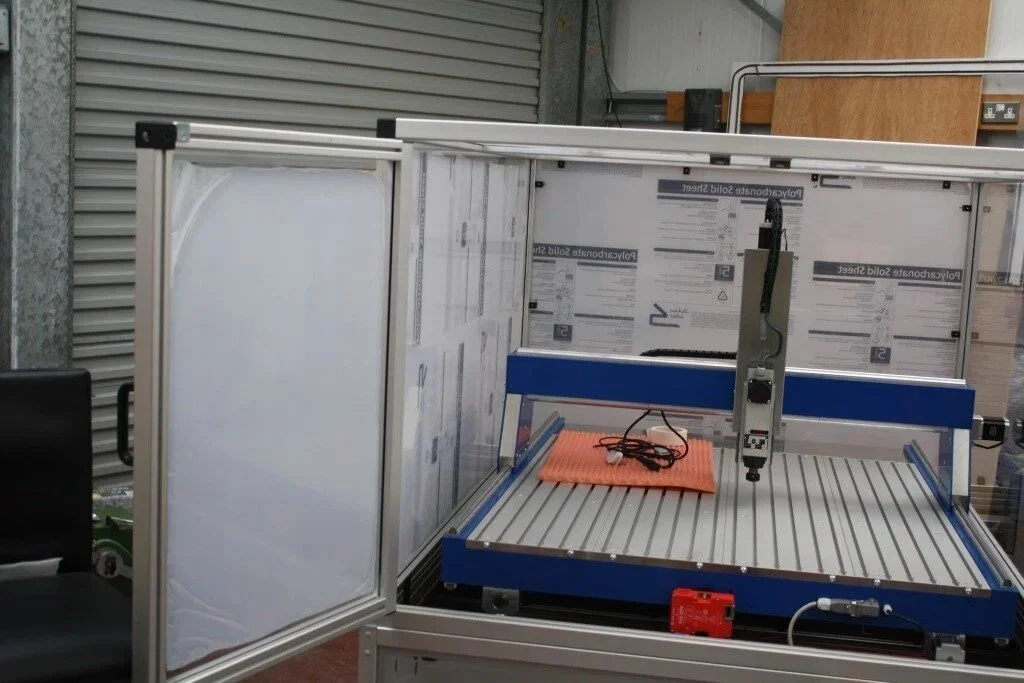

The JBEC 1259012 machine is the largest machine we offer in the professional series. The specified travel is 1200mm x 900mm in X and Y. If you're careful, you can realise up to 1350mm x 970mm. See below for some images and videos of the JBEC 1259012 CNC router. Please have a close look at all aspects of the machine and don’t hesitate to give us a call.

Specifications and Software

Please have a look here for images and videos of the JBEC 1259012 machine, and then pay special attention to the technical specifications and software pages.

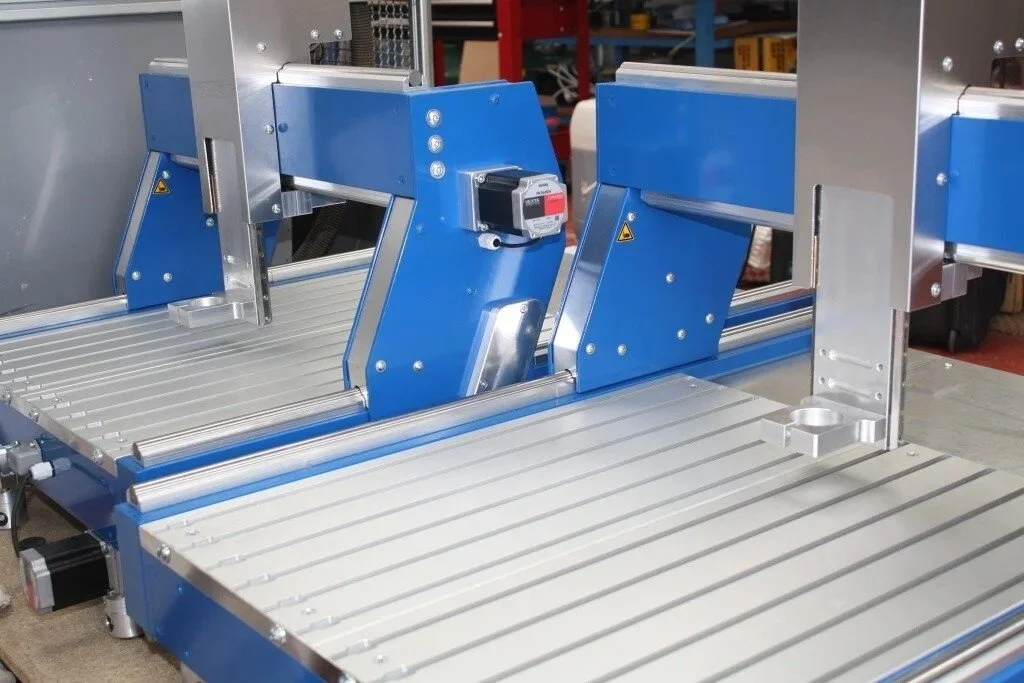

Machine travel

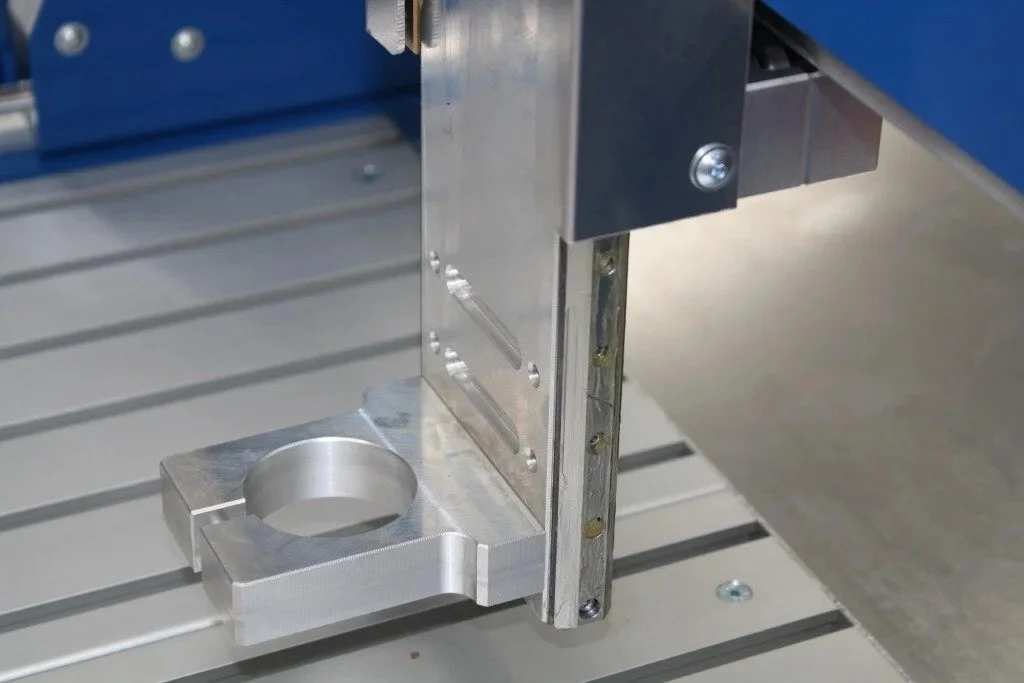

1250 mm (X) × 900 mm (Y) × 125 mm (Z). However, if you push her to her limits, you can get 1300mm x 960mm in the X and Y axes. Have a look here – you can see how the bed can be removed to allow for extra throat access for the Z-axis.

CNC Router Spindle Options

The machine can be configured with either a single-phase Kress spindle or a 3-phase high-frequency spindle (NOTE: still running on a single-phase supply through a VFD)

Feed Rates

We can machine at up to 4,000mm/min and in some cases higher, depending on the materials and cutters used. An industrial production machine must be capable of machining at well over 1,000mm/min and support a high-frequency, three-phase spindle.

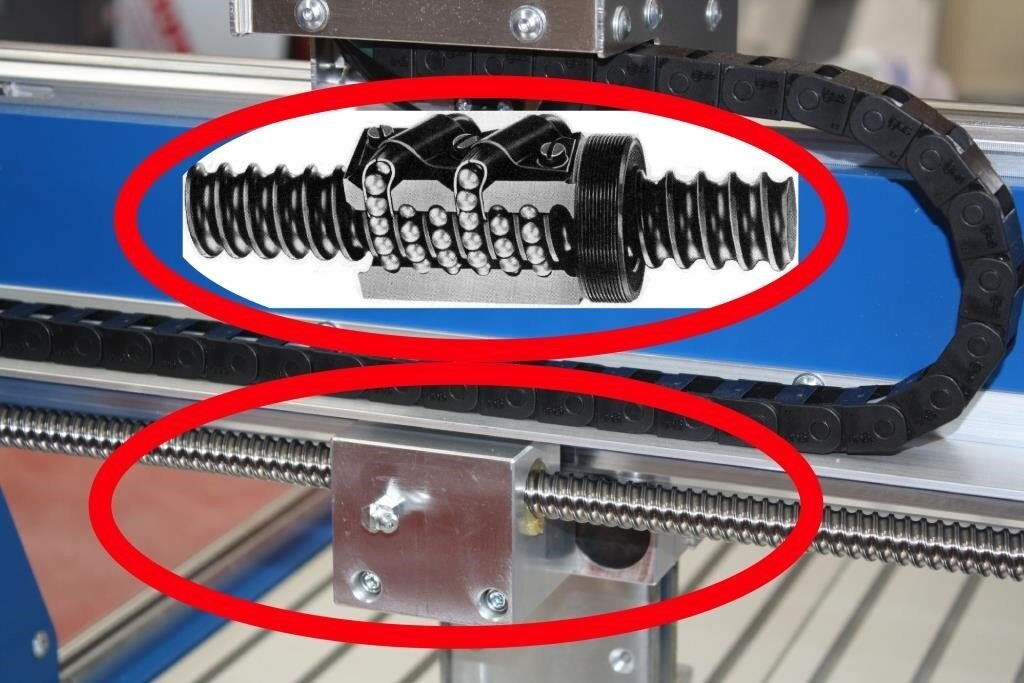

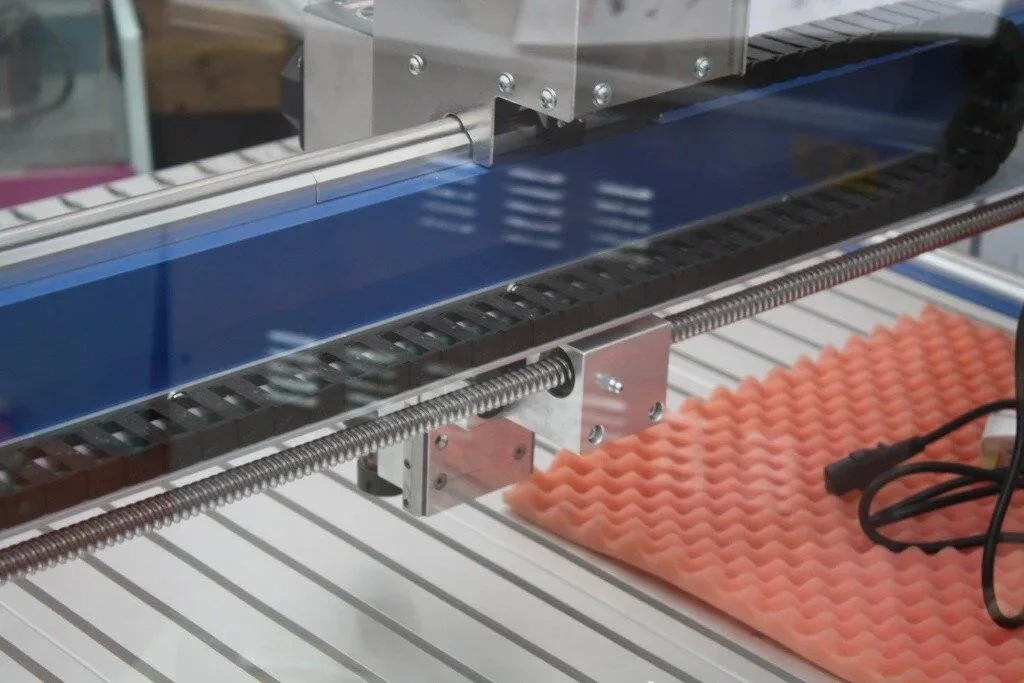

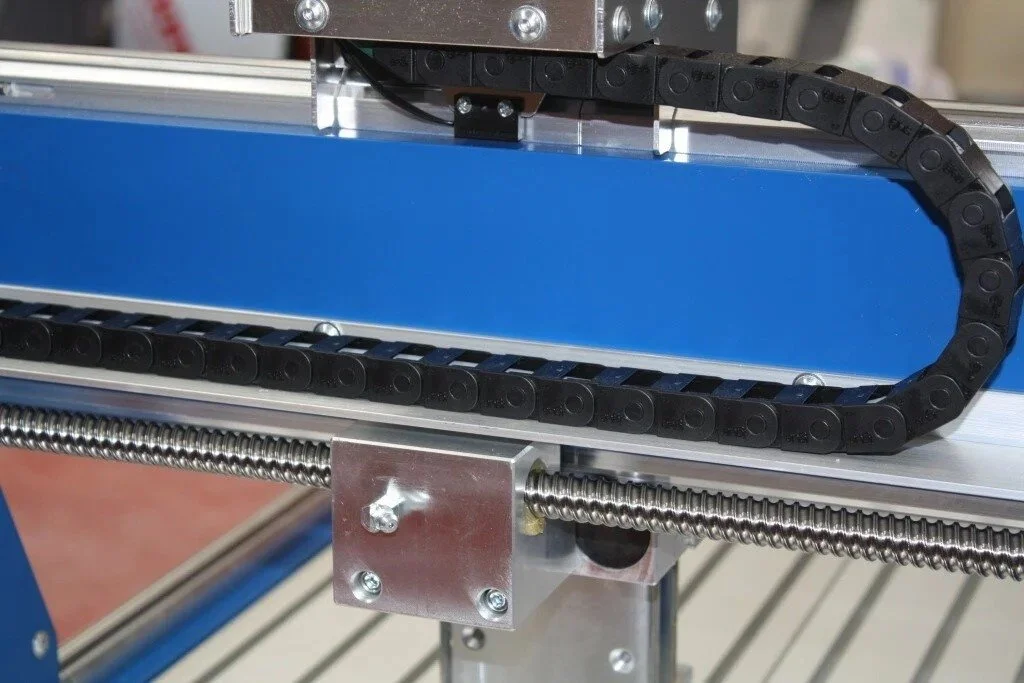

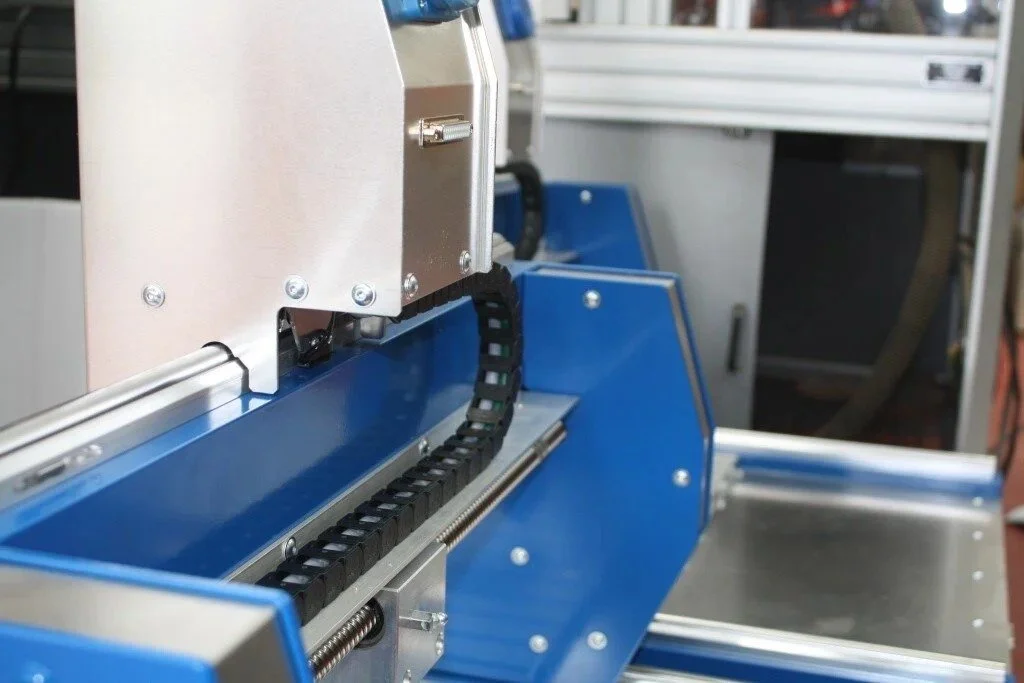

Drive System

All our professional CNC machines use ball screws. Ballscrews are not “leadscrews”. Ballscrews are not “trapezoidal” lead screws. Ballscrews have circular grooved shafts with rolling recirculating bearing elements on the nut. Leadscrews are well known for backlash. See here for more information. While software can be used to eliminate “backlash” generated when using leadscrews/trapezoidal screws, we believe it's best to minimise the backlash with hardware – hence we use ballscrews where the backlash is at a minimum. They don’t wear out as quickly, are virtually maintenance-free, and are the most accurate method for driving a CNC router.

Software

We offer a fully supported, integrated, complete solution. The CAD/CAM and control software we use can be installed on any Windows-based PC/Laptop. We don’t believe there is a disconnect between the machine and the system to generate the toolpaths. With our integrated solution, you can design, set up and machine all from one PC. This makes changes possible in seconds. No USB flash drive needed.

See below for some samples made on the JBEC professional CNC router series

Custom Lampshades

Custom Nameplates

Foamex machining samples

Birch Plywood Tables

See below for a number of sample videos of the JBEC professional CNC system