JBEC Modifications

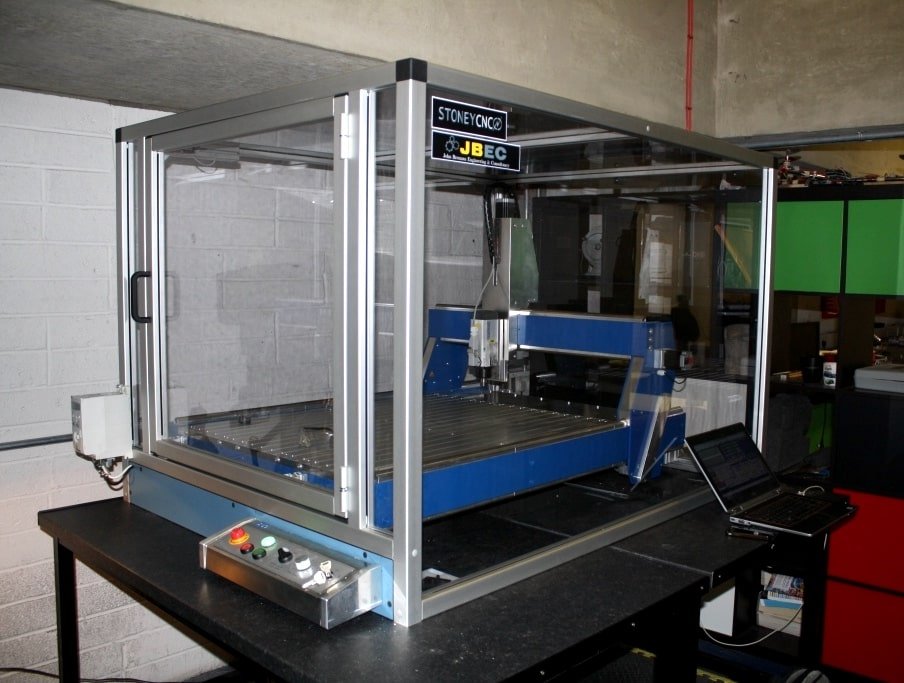

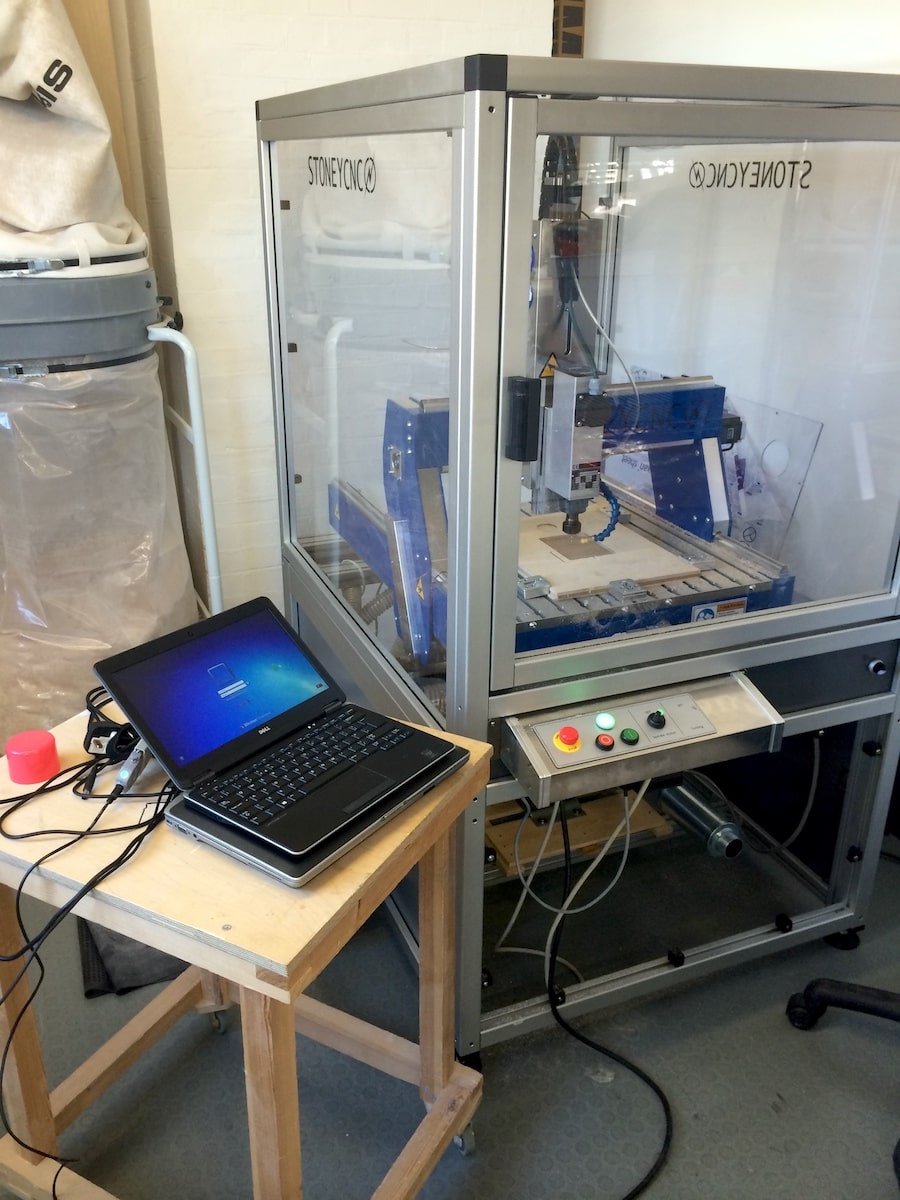

Enclosure Upgrade

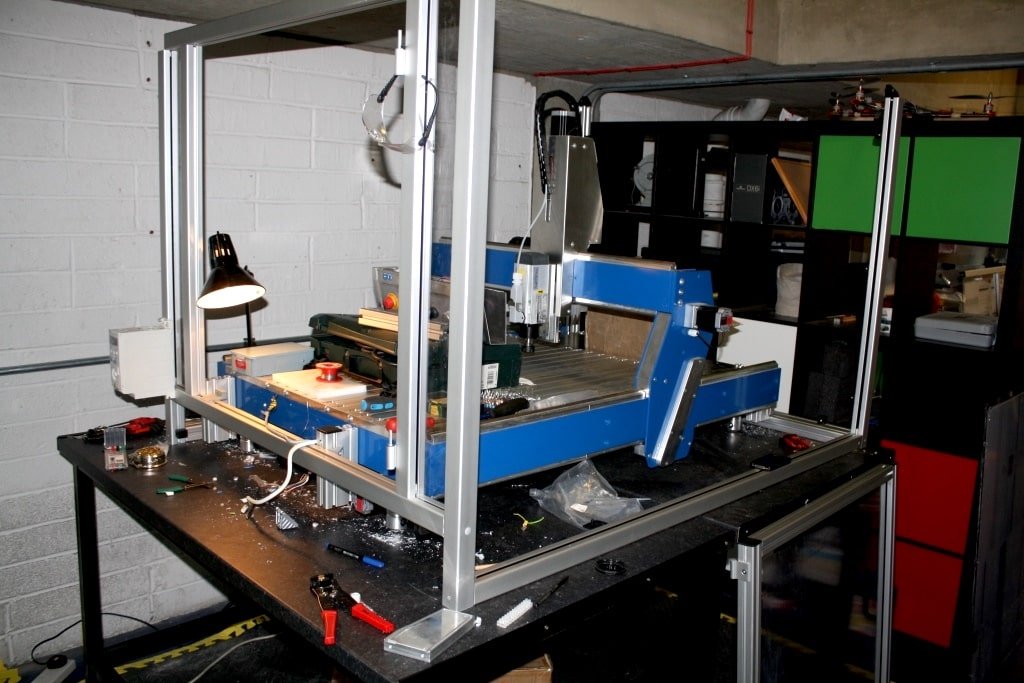

After installing a CNC router, it may be necessary to install an enclosure around the machine as an upgrade. This can be due to noise, safety, and other factors.

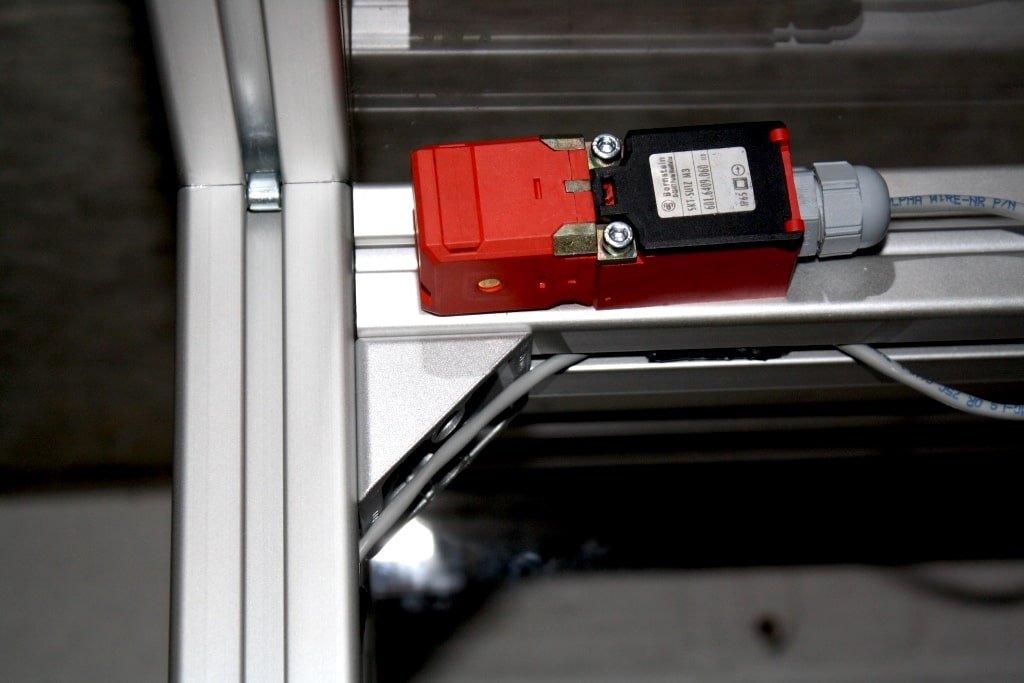

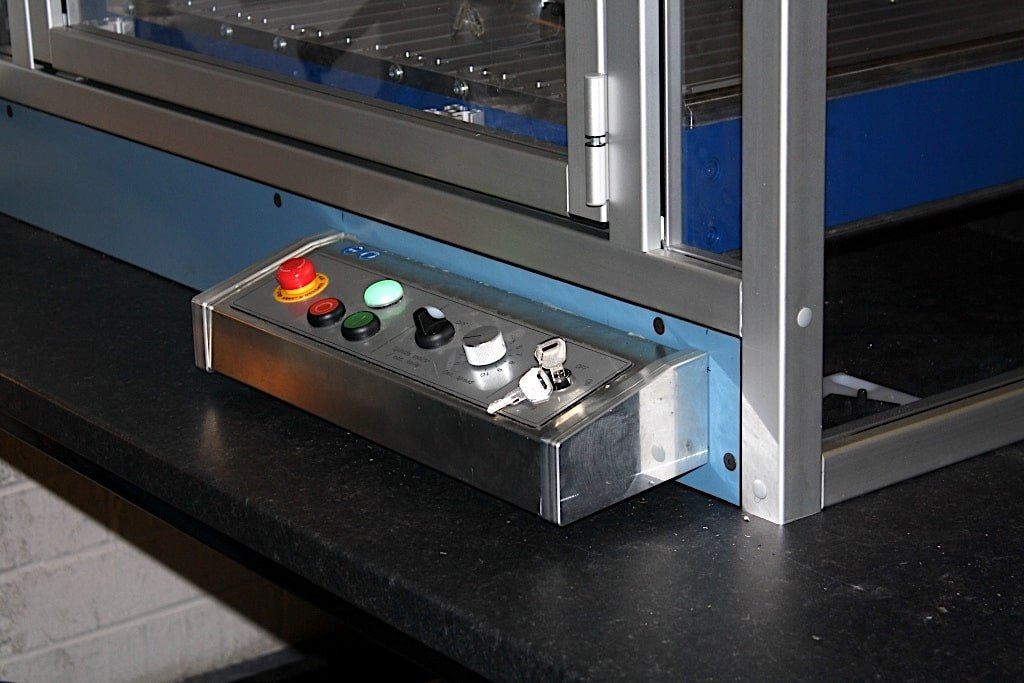

This option is possible after a tabletop installation of an open router. However, it is less cost-effective than installing the enclosure with the router. Some modifications are required to allow the router to be enclosed. As an example, a safety interlock switch is integrated into the no-volt release circuit of the machine power management system.

In addition to offering safety enclosures for our range of machines, we can also provide a custom enclosure for your CNC system. Just contact us for more information.

External Electronics

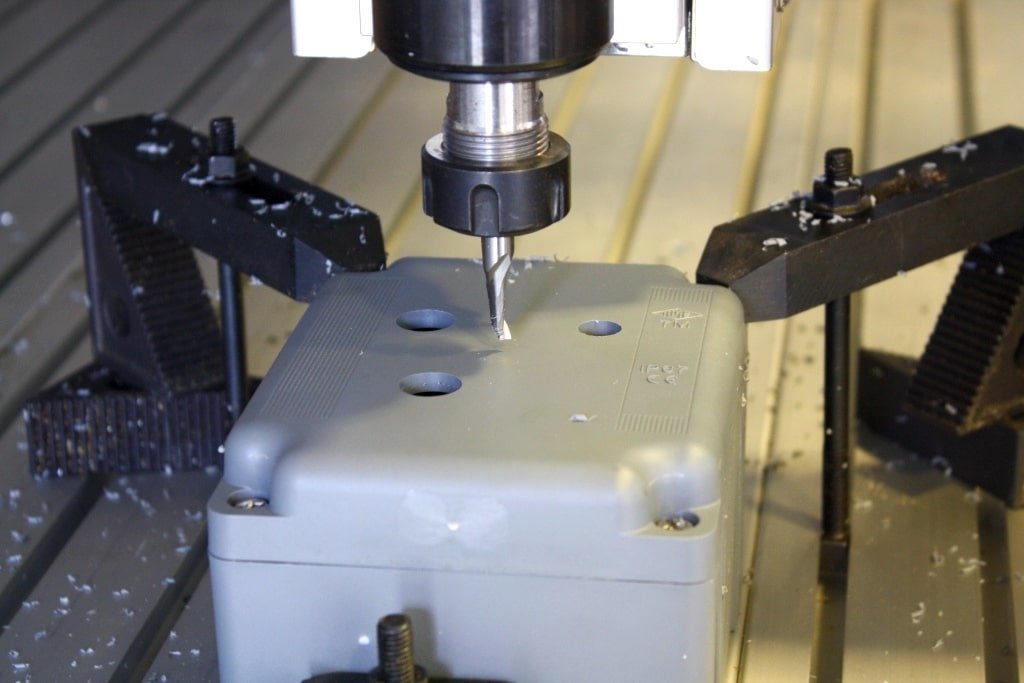

In some cases where the CNC router is to run with mist/spray coolant continuously, an external control unit is required to house and protect the control electronics from water ingress. For example, using a sprayer cooling system can significantly improve the stability of aluminium cutting and help keep materials like acrylics cool during machining. We use the dual-nozzle Fogbuster system when running with coolant.

High Quality Connectors

We use high-quality IP67 connectors to interface with the controller. The cables are routed at the rear of the machine and typically have 2-3 metres of length between the machine and the controller.

Z-Axis Throat Modification

Z-Axis Throat Height Flexibility

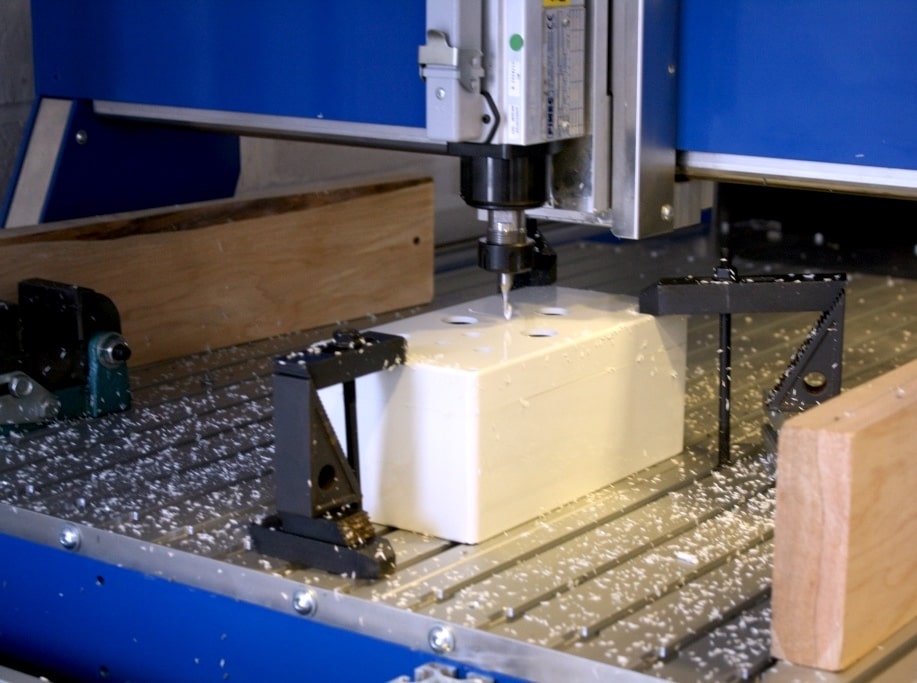

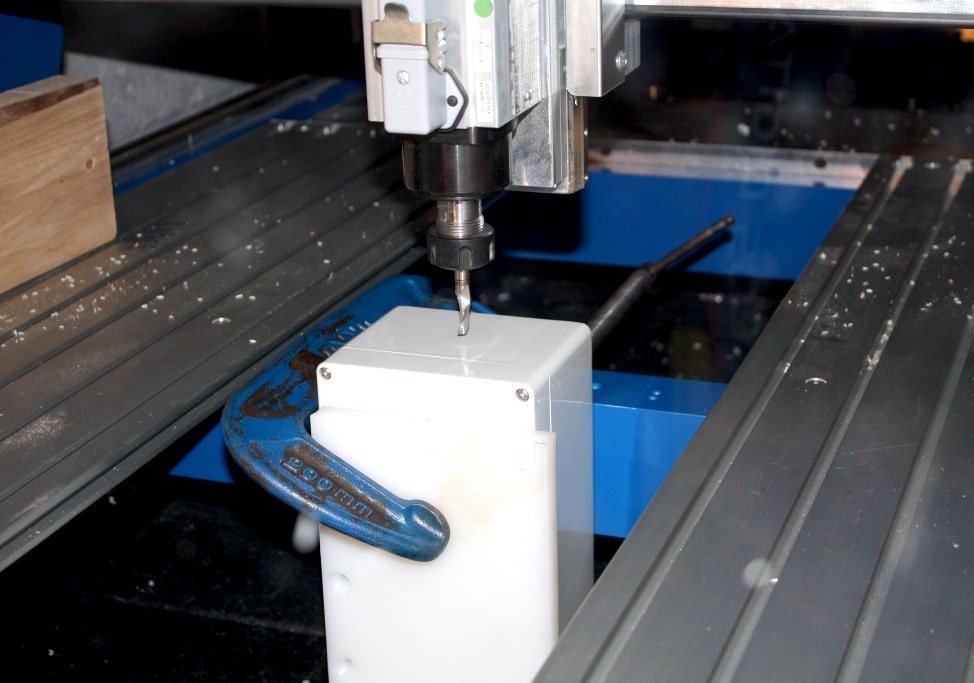

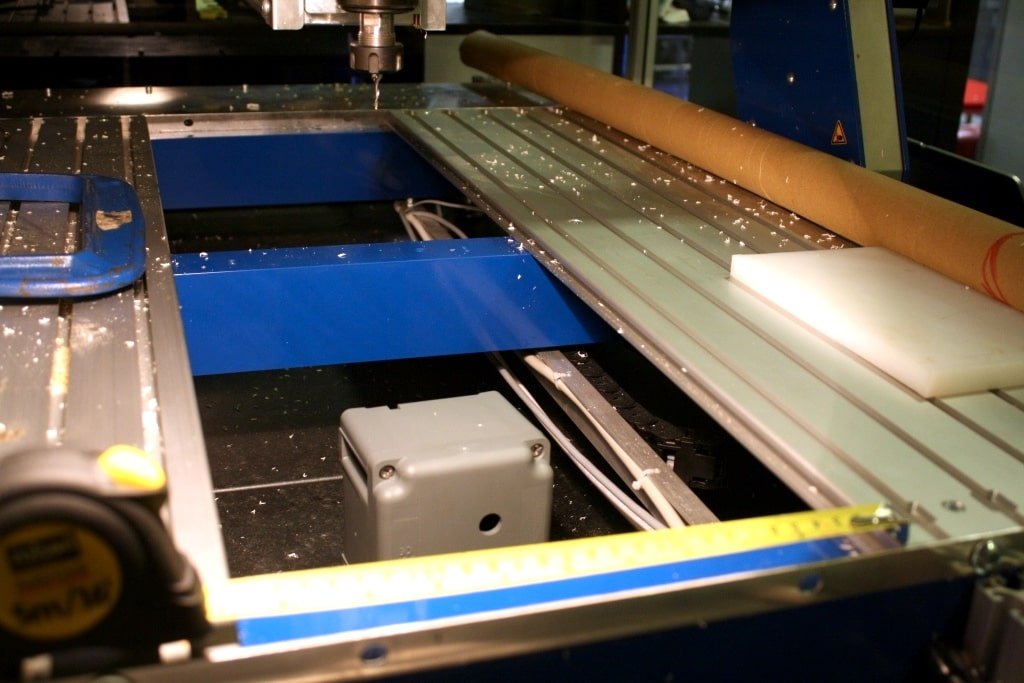

We were approached and asked about several performance aspects of the professional routers. One of which was “could we machine holes for cable glands on the end of a 600mm high enclosure box?” The Z-axis travel depth was not the issue here, as it was a simple 2D profile within the 3mm plastic enclosure. The problem was the ability to mount the long aspect ratio dimension of the enclosure into the machine.

Partial removal of the T-slot bed provides access through the frame to clamp the enclosure in place. The images below show this procedure. Note that cables are routed through the frame for the no-volt release circuitry in the control panel. Therefore, care must be taken when using this approach.

CNC Router Dust Shoe

Fixed Position Dust Shoe

We have been evaluating several designs and have converged on this model for our fixed-position dust shoe. The main aims when integrating this system were as follows.

Easily removable without any tools. Magnetically fixed in place was the best solution

Easy access to the collet for a tool change with the main dust shoe fixture in place

Management of the duct/extraction pipe at all times

Adjustable height of the shoe level relative to the workpiece

Efficient removal of swarf from the cutting zone

Easy replacement of the brush strip itself

Dust Shoe Performance

The shoe can be adapted to suit most duct and extraction system sizes. The advantage of a system fixed to the gantry as opposed to the spindle itself is that the brushes are always preventing the swarf from moving away from the cutting zone. The radial flow from the cutter and collet is the main contribution to the swarf being forced over the machine bed. The fixed shoe with a constant brush height prevents this.

4th-Axis Systems

We can provide a 4th-axis system for all our CNC routers. The 4th axis system shown here is a stepper motor-driven knife mounted instead of the spindle. The knife is driven and can be controlled such that the knife remains tangential to the cutting path.

We will soon have examples of where a 4th axis system is bolted to the bed of the machine for tuning-type operations.

Custom 4th-Axis System

Based on the same principle as the 4th-axis knife system, we designed a module to hold a fixture as specified by the customer.