Z-Axis

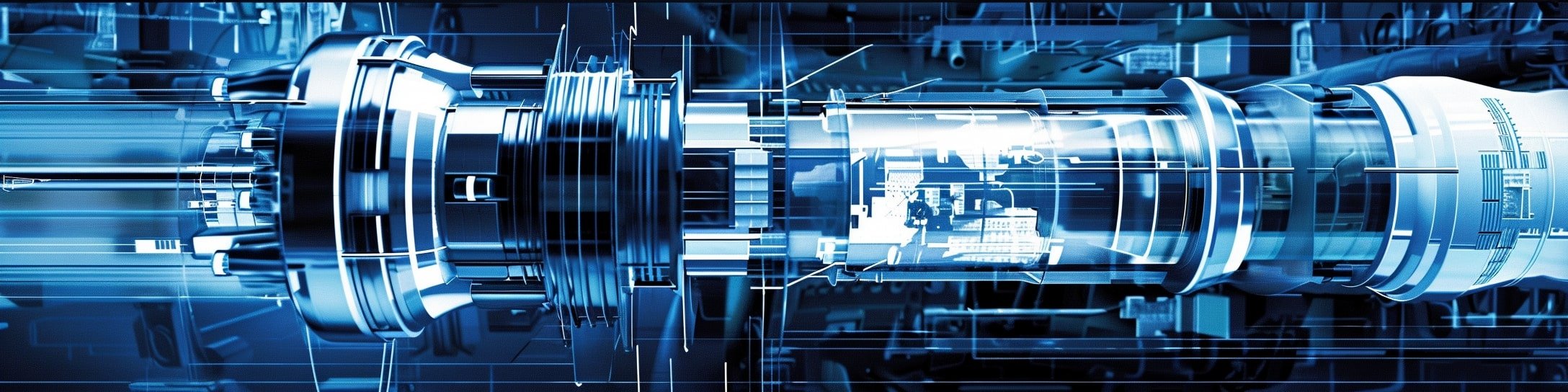

The Z-axis in CNC (Computer Numerical Control) machining represents the vertical axis in a three-dimensional coordinate system, commonly used in mills, lathes, routers, and other CNC machines. Movement along the Z-axis allows the cutting tool to move up and down, typically controlling the depth of the cut into the workpiece.

The Z-axis is a crucial component of CNC machines, providing vertical motion of the tool or spindle relative to the workpiece. It controls the depth of cuts, drilling, and engraving, making it an essential axis for achieving precise and accurate machining results. For those new to CNC machining, it is vital to learn how the Z-axis interacts with the X and Y axes to execute 3D cutting operations. Understanding Z-axis functionality is key to mastering depth settings, avoiding tool crashes, and ensuring high-quality outputs in manufacturing processes.

Key Points about the Z-Axis

Vertical Movement

The Z-axis provides vertical movement of the cutting tool relative to the workpiece, allowing it to penetrate or retract from the material.Depth Control

In machining operations, the Z-axis controls the depth of the cut, making it critical for achieving specific thicknesses, grooves, or contours in the part.Multi-Axis Machining

In more advanced CNC systems, the Z-axis works in conjunction with other axes (such as X, Y, and rotational axes) to enable complex 3D shaping and precision machining.

The Z-axis in CNC machining is the vertical axis that controls the depth of cuts, allowing precise vertical movement of the tool for accurate shaping, cutting, and contouring of parts.