Wire EDM

Also, see Electrical Discharge Machining

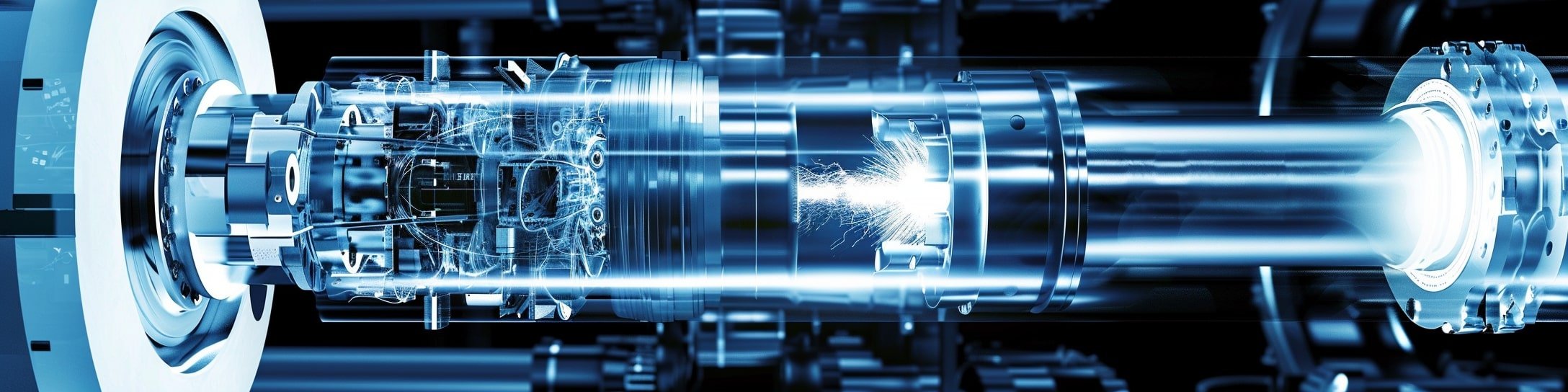

Wire EDM is a precision machining process that uses electrical discharges (sparks) to cut through conductive materials. A continuously fed wire, typically brass or copper, acts as the cutting electrode. The wire and workpiece are submerged in dielectric fluid, where controlled sparks vaporise material without the wire making physical contact, enabling intricate, highly accurate cuts.

Wire EDM (Electrical Discharge Machining) is a precision cutting technology widely used across various industries, including aerospace, medical, and automotive, for creating intricate components with exceptional accuracy. This process involves using a thin electrically charged wire to cut through conductive materials, offering unmatched precision for complex geometries and tight tolerances. Wire EDM is particularly effective for tasks like hole drilling and producing fine details on hard metals. Its ability to handle a range of materials and thicknesses ensures consistent quality in finished parts. This advanced technology has become essential in industries requiring high precision and reliability.

Here's a closer look at how the Wire EDM process works:

Electrode

In Wire EDM, a thin wire, typically made from brass, copper, or tungsten, serves as the electrode. This wire, which can be as thin as 0.1 mm, is fed continuously from a spool through the workpiece.Process

The wire and the workpiece are submerged in a tank of dielectric fluid, often deionised water. As an electrical current is applied, the wire never actually touches the workpiece. Instead, a series of sparks jumps the gap and vaporises a small portion of the workpiece.Machining

The process is computer-controlled, enabling exact cutting along predetermined paths. As the wire travels through the workpiece, it erodes the material along the route, effectively "cutting" it.Applications

Wire EDM is commonly used for cutting shapes and profiles, creating punches, tools, and dies from hard metals that are difficult to machine with other methods. It's also used to make small holes and contours, as well as to create parts with tight tolerances.

One of the main advantages of Wire EDM is its ability to produce intricate, complex shapes with high precision. It can cut intricate contours or cavities in pre-hardened steel without heat treatment. However, Wire EDM can be a slow process, often making it more expensive than other machining methods. Also, because it uses electrical discharges to cut, the process can only be used with electrically conductive materials.