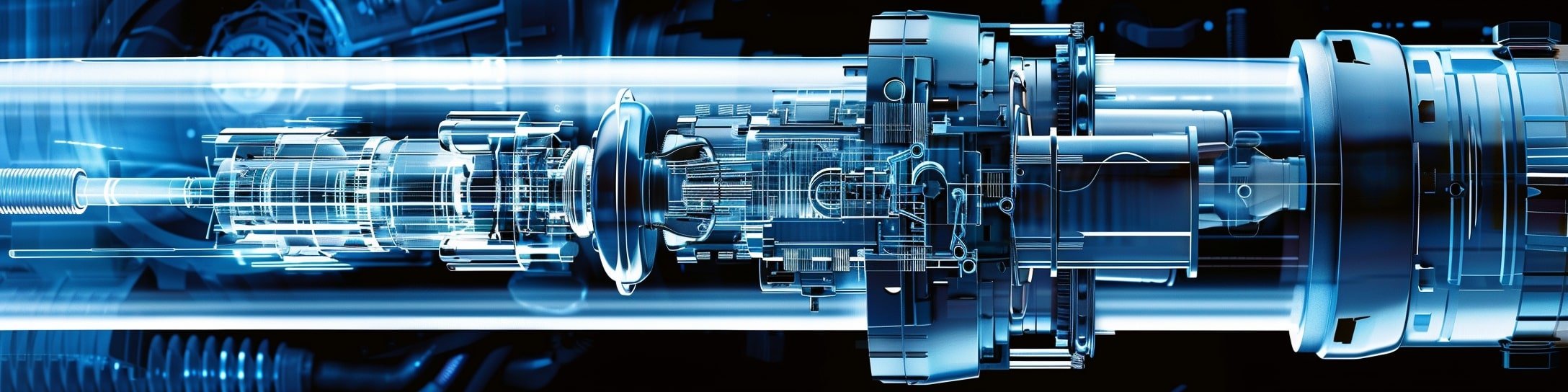

Screw Machine

A screw machine is an automated lathe designed explicitly for the high-speed production of small, precise parts such as screws, bolts, fittings, and other cylindrical components. Screw machines are ideal for producing high-volume, repetitive parts with intricate details, often used in industries such as automotive, electronics, aerospace, and medical device manufacturing. These machines can work with various materials, including metals, plastics, and composites.

Key Characteristics of Screw Machines

Automatic Operation

Screw machines are highly automated, using cams or CNC (Computer Numerical Control) systems to control cutting, drilling, and other operations, allowing them to produce parts with minimal human intervention.Multi-Spindle vs. Single-Spindle

Screw machines are available in single-spindle and multi-spindle configurations. Multi-spindle screw machines have multiple spindles that can work on multiple parts or different parts of a single part simultaneously, significantly increasing production speed.Bar Stock Feeding

Screw machines are typically designed to work with bar stock, feeding it through the spindle to continuously cut parts of a designated length.Precision and Speed

Screw machines are known for their fast cycle times and ability to hold tight tolerances, making them suitable for producing intricate parts quickly and with high precision.

Types of Screw Machines

Swiss Screw Machine

Known for its high precision, Swiss screw machines use a guide bushing to support the material near the cutting tool, reducing deflection and enabling very fine tolerances. They are often used for small, intricate parts.Automatic Screw Machine

Also known as a cam-driven screw machine, it uses a series of cams to control the movement of cutting tools. These machines are ideal for high-volume production but have less flexibility than CNC-controlled machines.

Advantages of Screw Machines

High Production Speed

Screw machines are optimised for rapid part production, making them ideal for high-volume manufacturing.Consistency and Repeatability

With automated control, screw machines maintain consistent quality across thousands or millions of parts.Cost-Effective for Large Runs

High efficiency and automation reduce labour costs and setup time, especially advantageous for large production runs.

A screw machine is an automated lathe used for high-speed, high-volume production of small, precise parts. Available in single-, multi-spindle, and Swiss configurations, screw machines excel at rapid, repeatable manufacturing with tight tolerances, making them essential for industries that require large quantities of detailed, cylindrical components.