CNC Turning

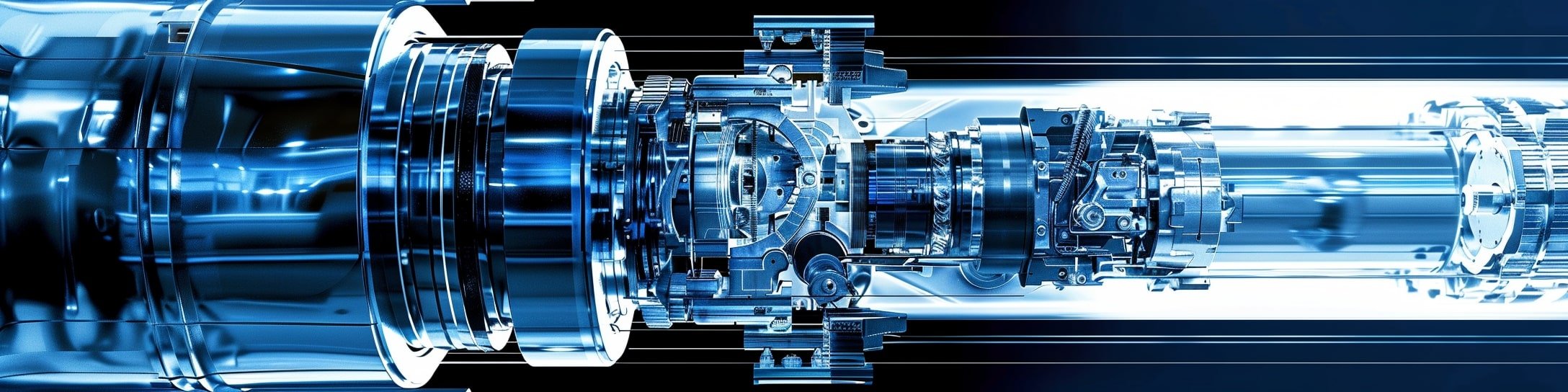

CNC Turning is a machining process that uses Computer Numerical Control (CNC) to automate the rotation of a workpiece while a stationary cutting tool removes material to create cylindrical shapes and features. In CNC turning, the workpiece is held and rotated in a spindle, allowing the cutting tool to precisely remove material along the workpiece's outer diameter (OD) or inner diameter (ID), depending on the operation. CNC turning is commonly performed on CNC lathes or turning centres.

CNC turning is a precise manufacturing process that complements CNC milling by shaping a rotating part using cutting tools on a lathe. This method excels at producing cylindrical components at high speed and with high accuracy, ensuring superior quality in the final product. CNC turning offers versatile capabilities, allowing the creation of complex geometries, including threading, grooving, and facing. With advanced tool-changing systems and automated programming, CNC turning is a reliable solution for high-precision manufacturing across industries, delivering consistent results for both custom parts and large-scale production.

Key Characteristics of CNC Turning

Rotational Machining

CNC turning is used for rotational parts, in which the workpiece rotates while the cutting tool remains fixed. This process is ideal for producing round, symmetrical parts.Multiple Operations

CNC turning machines can perform a range of operations, including turning, facing, boring, threading, and grooving. Multi-axis CNC lathes can perform complex features and contours, often without needing additional setups.Automated Precision

CNC turning is controlled by digital programming (typically in G-code), enabling high precision, repeatability, and consistency across multiple parts. This minimises the need for manual adjustments and reduces human error.

Applications of CNC Turning

CNC turning is widely used to produce cylindrical parts and components across industries such as automotive, aerospace, electronics, and medical. Common applications include:

Manufacturing shafts, pins, and bushings

Producing threaded components like screws and bolts

Creating intricate, rounded shapes on complex parts like turbine components and medical devices

Advantages of CNC Turning

High Precision … CNC turning provides tight tolerances and accurate dimensions, ensuring uniformity across parts.

Efficiency … automated CNC programming enables faster production and more efficient material removal.

Versatility … CNC turning can work with a wide range of materials, including metals, plastics, and composites, to create complex profiles and detailed features.

CNC Turning is a CNC machining process that involves rotating a workpiece while a fixed cutting tool removes material to produce precise, cylindrical parts. This process offers high accuracy, repeatability, and efficiency, making it ideal for manufacturing round or symmetrical components across various industries.