CNC Software ⚙️

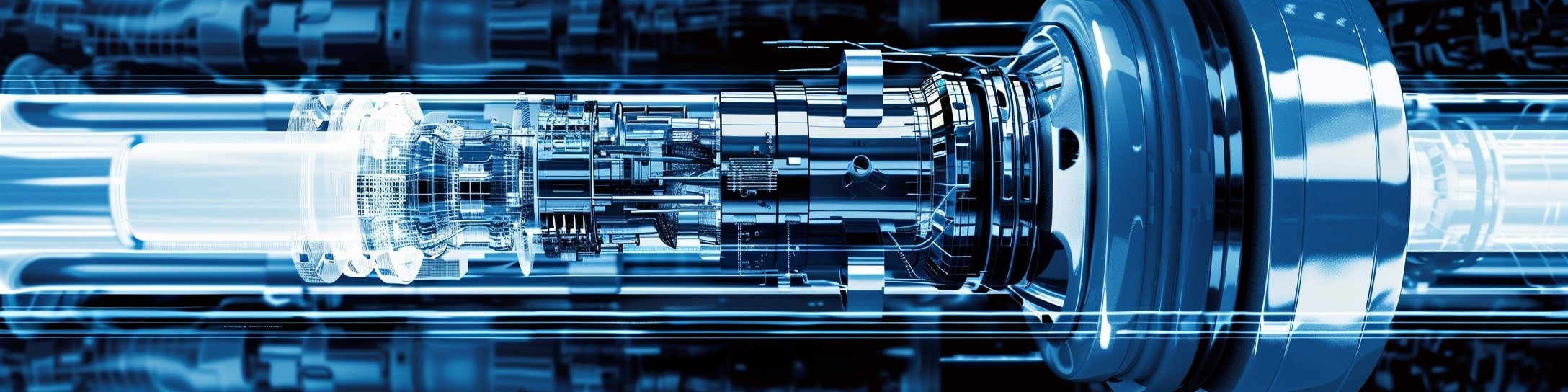

CNC software encompasses a suite of computer programs designed to facilitate the design, control, and operation of Computer Numerical Control (CNC) machines, including CNC mills, lathes, routers, plasma cutters, and laser cutters. These software tools allow users to create digital designs, generate machine-readable code, and precisely control CNC machines throughout the manufacturing process.

Types of CNC Software in the CNC Workflow

CAD (Computer-Aided Design) Software

CAD software is used to create detailed 2D or 3D digital models of the parts or components to be manufactured. It provides the foundation for the entire CNC workflow, ensuring precise geometry and dimensions. Examples include AutoCAD, SolidWorks, and Fusion 360.CAM (Computer-Aided Manufacturing) Software

CAM software converts CAD models into machine-readable code, typically G-code or M-code, which instructs the CNC machine on the specific steps to execute during the machining process, such as tool movements and cutting paths. Examples include Mastercam, GibbsCAM, and HSMWorks.CNC Control Software

CNC control software interprets the G-code or M-code from the CAM program, directing the CNC machine’s movements, speeds, and other parameters. This software communicates directly with the CNC machine’s controller, enabling precise control over operations. Examples include Mach3, LinuxCNC, and GRBL.Simulation and Verification Software

This software allows users to virtually simulate and verify the CNC machining process, identifying potential issues, optimizing toolpaths, and estimating machining time before actual production. Simulation helps avoid costly errors, ensuring a smoother workflow. Examples include VERICUT, NCSIMUL, and CIMCO Edit.Post-Processors

Post-processors convert the toolpaths generated by CAM software into a specific G-code or M-code format compatible with the CNC machine’s controller. They ensure seamless communication between the CAM output and the machine controller, adapting code to the requirements of different CNC machines.

Benefits of CNC Software

Precision and Efficiency

CNC software enhances precision, enabling complex designs to be executed accurately and consistently across multiple parts.Automation

CNC software automates machining tasks, minimizing manual intervention, and reducing errors while optimizing material use.Cost and Time Savings

By automating design, code generation, and verification, CNC software reduces production times and material waste, contributing to lower production costs.Flexibility in Design and Production

Users can easily adjust designs, making CNC software suitable for rapid prototyping, custom parts, and high-volume manufacturing alike.

Applications

CNC software is integral in industries such as automotive, aerospace, electronics, medical manufacturing, and more, where high precision, repeatability, and efficiency are critical.

CNC software is essential for designing, programming, and controlling CNC machines, enabling manufacturers to produce complex parts with high accuracy and efficiency. From CAD design to CAM code generation, machine control, and virtual simulation, CNC software facilitates an automated and streamlined manufacturing process across a wide range of applications.