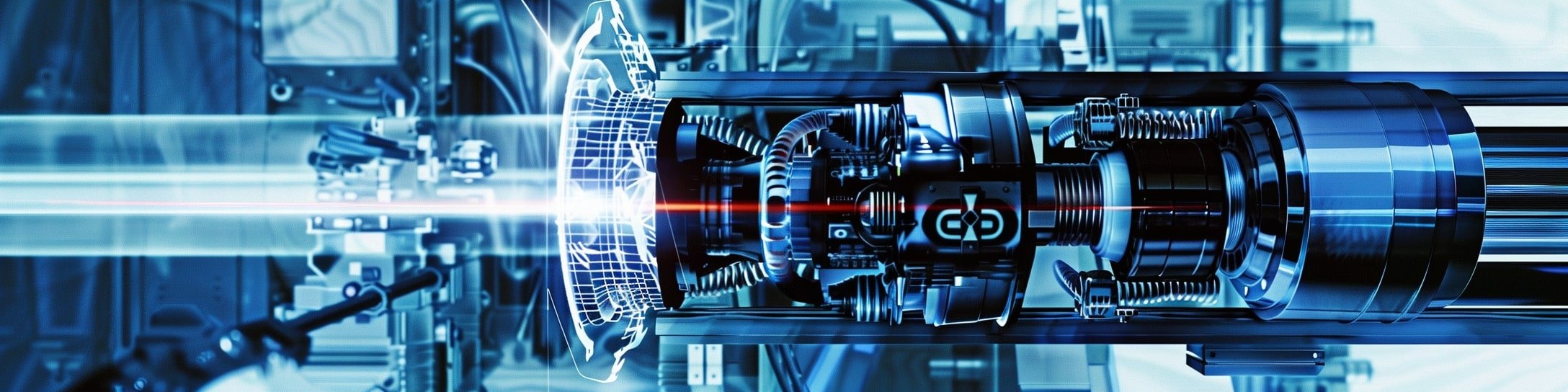

CNC Laser Cutter ⚙️

A CNC (Computer Numerical Control) laser cutter is an automated machine that uses a focused laser beam to cut or engrave various materials, including wood, plastic, acrylic, textiles, and certain metals. Combining the precision of CNC technology with the versatility of laser cutting, these machines are capable of producing highly accurate and efficient cutting results.

Key Features of CNC Laser Cutters

How It Works

CNC laser cutters operate based on digital design files, usually created using CAD (Computer-Aided Design) software. These files are converted into G-code by CAM (Computer-Aided Manufacturing) software, which provides step-by-step instructions for the machine. The CNC laser cutter then follows these instructions to control the movement of the laser head and workpiece across multiple axes (X, Y, and sometimes Z), while adjusting parameters such as laser power and cutting speed.

Laser Cutting Process

A high-powered laser beam is focused on the material’s surface, generating intense heat. Depending on the material and settings, this heat causes the material to melt, burn, vaporize, or be blown away by a jet of gas, resulting in a clean, precise cut. The non-contact nature of the process minimizes material deformation and damage.

Advantages of CNC Laser Cutters

Precision and Accuracy:

CNC laser cutters can produce intricate designs and detailed cuts with exceptional accuracy. The precise control over the laser’s movement and cutting parameters ensures high-quality results, even for complex shapes.Repeatability:

Once programmed, CNC laser cutters can repeatedly produce identical parts with consistent accuracy, making them ideal for large production runs or projects requiring multiple identical components.Non-Contact Cutting:

Since laser cutting doesn’t involve physical contact with the material, there is a reduced risk of damaging delicate workpieces. Additionally, this minimizes tool wear and eliminates the need for frequent maintenance or replacement of cutting tools.Reduced Labor Costs:

CNC laser cutters are highly automated and require minimal human intervention. This reduces the need for skilled operators and lowers overall labor costs, while still delivering efficient production.

Applications

CNC laser cutters are widely used in industries such as:

Electronics: For cutting and engraving circuit boards and enclosures.

Automotive and Aerospace: For precision cutting of components and parts.

Textiles and Apparel: For cutting fabrics and intricate patterns.

Signage and Advertising: For creating signs, logos, and intricate lettering with clean, sharp edges.

A CNC laser cutter is a powerful and versatile tool for cutting and engraving a wide range of materials with high precision and efficiency. Its non-contact cutting method, automation, and ability to handle intricate designs make it an ideal choice for industries that require consistent, high-quality results with minimal material waste.