CNC Control Software ⚙️

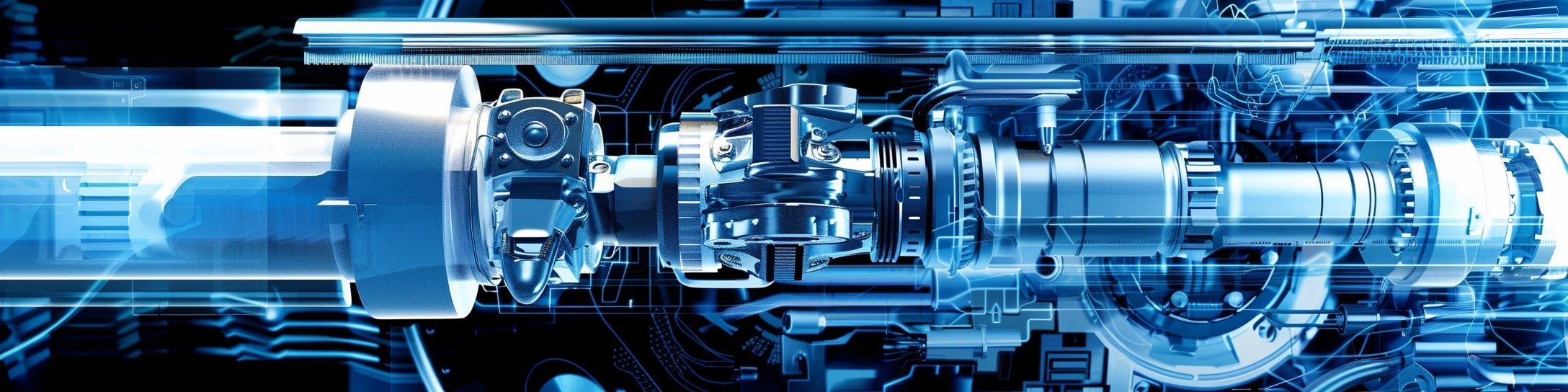

CNC control software, also known as CNC software, is a specialized program or suite of programs that manages the operation of CNC (Computer Numerical Control) machines, such as mills, lathes, routers, plasma cutters, and laser cutters. This software interprets digital design files and converts them into machine-readable code—typically G-code—providing precise instructions to guide the movement of cutting tools and workpieces through the machining process.

Key Features of CNC Control Software

CAD (Computer-Aided Design) Integration

CNC control software can import or directly create digital design files, such as 2D drawings or 3D models, which form the basis for the machining operations.Toolpath Generation

The software calculates the most efficient tool paths for the cutting tools to follow, factoring in the design, machining operations, and material characteristics to optimize cutting accuracy and efficiency.G-code Generation

Toolpaths are translated into G-code, a machine-readable language that provides the CNC machine with step-by-step instructions, including movement, speed, and tool engagement parameters.Machine Simulation

Many CNC control programs include a simulation feature, allowing operators to visualize and test the machining process. Simulations help identify potential issues like tool collisions, ensuring that toolpaths and parameters are optimal before actual machining.Post-Processing

Post-processors within the software tailor G-code for specific CNC machines or controllers, ensuring compatibility and smooth execution of commands.

Benefits of CNC Control Software

Precision and Accuracy

By automating and precisely executing tool movements, CNC control software ensures parts are produced with high accuracy, meeting exacting tolerances.Efficiency and Productivity

The software’s ability to automate toolpath planning, G-code generation, and error-checking increases efficiency, allowing CNC machines to operate continuously and reducing setup times.Repeatability

CNC control software allows identical parts to be produced consistently, supporting mass production or high-precision, low-volume manufacturing.Error Reduction

Simulation and post-processing features minimize the likelihood of machining errors, saving time and reducing material waste.

Applications

CNC control software is widely used across industries requiring precise, complex parts, including:

Automotive and Aerospace: Manufacturing engine parts, turbine components, and complex assemblies.

Medical and Electronics: Producing intricate parts for medical devices and electronic components.

Woodworking and Metalworking: Creating custom and mass-produced parts, furniture, and decorative items.

CNC control software is an essential tool in modern machining, enabling precise, automated control of CNC machines to produce parts efficiently and accurately. By integrating design, toolpath planning, simulation, and post-processing, CNC control software enhances productivity, repeatability, and precision across a wide range of manufacturing applications.