Automatic Wire Feed ⚙️⚙️

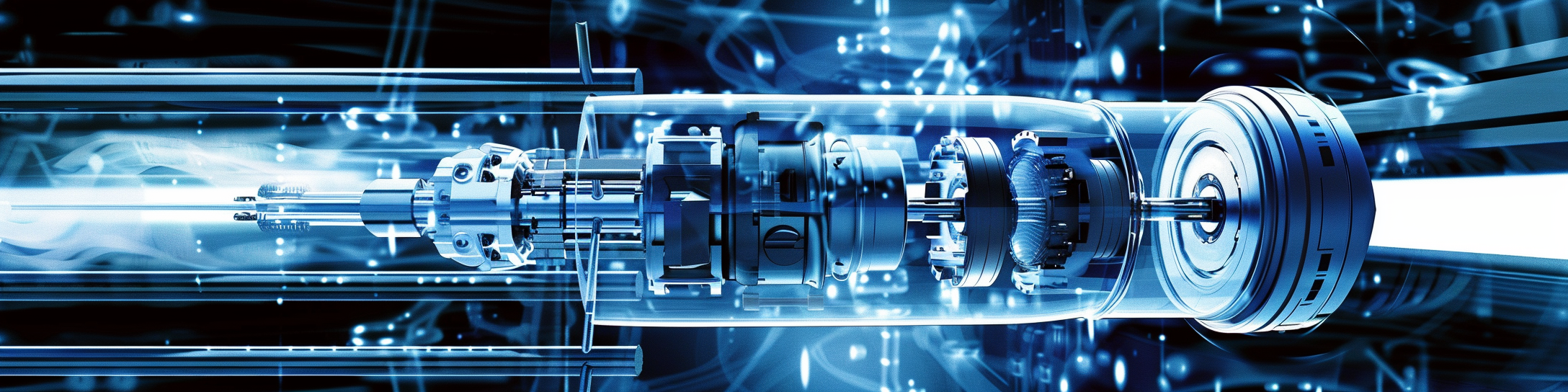

Automatic Wire Feed is a feature commonly found in Wire Electrical Discharge Machining (Wire EDM) machines, enabling the continuous and automated feeding of wire during the cutting process. This feature automatically supplies fresh wire from a spool to the cutting zone, allowing for uninterrupted operation and consistent precision.

Automatic wire feed is a critical feature in industrial welding and machining equipment, particularly in applications requiring TIG torches and arc welding processes. This wire feeder technology automatically delivers wire to the work area, maintaining a steady arc and improving efficiency across a range of welding machines and power settings. As a product innovation, it supports consistent precision and is indispensable in industrial contexts where continuous, high-quality output is essential. This technology allows for extended machine operation without manual wire replacement, boosting productivity and supporting intricate, high-precision applications across various industries.

Key Characteristics of Automatic Wire Feed

Continuous Operation: The automatic feed system advances the wire as it wears down, enabling continuous cutting without manual intervention. This is particularly useful for long or complex cuts that require extended machining time.

Improved Accuracy and Consistency: By consistently feeding fresh wire, the system ensures that the cutting tool maintains high accuracy and quality throughout the machining process, minimizing wear-related issues.

Efficiency: Automatic wire feed reduces downtime, as operators do not need to pause the machine to replace the wire manually. This increases productivity, especially in high-precision and high-volume production environments.

Automatic Re-Threading: Many advanced automatic wire feed systems include automatic re-threading capabilities, which enable the wire to be automatically re-threaded through the workpiece if it breaks, further minimizing interruptions.

Applications

Automatic wire feed is essential in industries that rely on Wire EDM for intricate, high-precision parts, including aerospace, medical, automotive, and mould-making sectors. Typical applications include:

Cutting complex shapes in hardened materials

Producing fine features or intricate contours with high accuracy

Machining parts that require consistent and high-quality surface finishes

Automatic Wire Feed is a feature in Wire EDM machines that provides a continuous supply of wire for uninterrupted, high-precision cutting. It enhances efficiency, accuracy, and productivity by minimizing manual intervention, making it indispensable in precision machining applications.