CNC Router Retrofits

Retrofit work to existing CNC machines

Retrofitting machines with new drive systems is a heavy heavy surgery for any machine. Ballscrew housings and end conditions are tricky to integrate and require time and consideration. We can offer a range of retrofitting solutions, however often the cost of a complete retrofit with new ball screw drives often can compete with the cost of a new machine.

Denford Conversion to USM

Details on a Denford 3 Axis milling machining with tool changer that was converted to a 3 Axis CNC Ultrasonic impact machining system.

Chinese CNC Machine Setup

Details on commissioning a Chinese CNC machine where the customer needed help to set up and commission a privately imported Chinese machine.

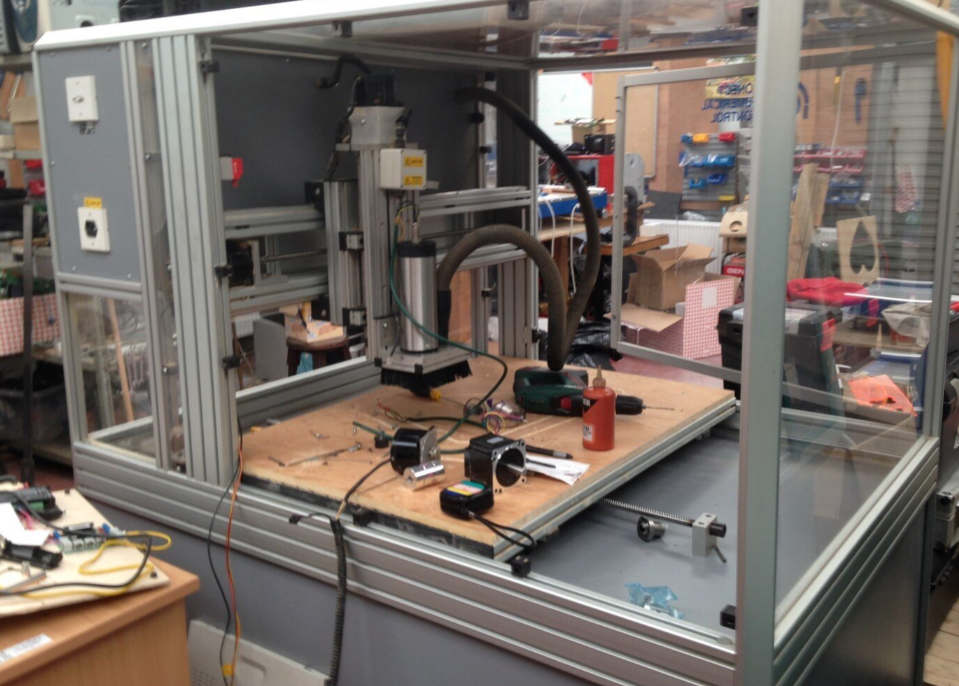

Connect CNC Conversion

Details showing a fully enclosed Connect CNC donor carcass machine that was upgraded with a new Y-axis ballscrew, spindle, and revamped electronics.

CNC Control Upgrade

More information on a project where we upgraded a machine to a new controller as the original control electronics died due to aluminium shavings in the control box during transport to Mick’s garage.

Contour CNC Mill Upgrade

Details on an upgrade where we rebuilt a contour milling machine and converted the control system to Mach3.

Linear Slide Upgrade

Details where we upgraded a machine with new slides on the X and Y axes to improve the accuracy of the machine.

Denford TRIAC Conversion to Mach3 | UCCNC

Details on a Denford 3-axis milling machine with a tool changer that was converted to a 3-axis CNC ultrasonic impact machining system.

Hurco Hawk 5M Conversion to AC Servo

The Hurco Hawk CNC milling machine has been converted to new control and is back up and running.

Rishton M10 Conversion to UCCNC/Mach3

A Rishton M10 is now under UCCNC and Mach3 control with full new brains.