What to look for in a CNC router?

-

This page is aimed to help you focus on key aspects that are important when you are considering a CNC router system.

This page is not aimed to help sell our products, it is aimed at showing you how to make an informed decision.

We encourage all our customers to do as much research as possible on all aspects of a system before making a decision and we encourage people to shop around.

The main points here may help to explain why some machines are more expensive than others. The most important message to take from this page is that you should consider the total cost of ownership of a machine.

Purchasing a CNC machine is not about the bottom line at the point of sale like it is when you buy a power tool in the hardware store. A CNC machine is a production system that requires time and effort and consideration. A huge part of the customer journey is the support aspect.

Anyone can sell CNC machines – it is another question however to support CNC systems.

-

We ask all our customers to consider the expectations you have in terms of the machine performance:

Maintenance

Support

Materials Cut

Speed of cut

Tolerances

Tool Changing

Consumables

Upgrades

these considerations will help us to help you identify a machine that is fit for purpose and within budget constraints.

If we cannot spec a system that we feel is fit for purpose within a budget constraint of a customer – then we decline to provide a machine – it generates a false economy.

A cheaper machine will save you money now – but if it is not fit for purpose then over the lifetime of the machine any savings will not transfer through.

This page is aimed to help you focus on key aspects that are important when you are considering a CNC router system. This page is not aimed to help sell our products, it is aimed to show you why we have chosen the designs and approaches we have adopted. We encourage all our customers to do as much research as possible on all aspects of a system before making a decision and we encourage people to shop around. The main points here may help to explain why some machines are more expensive than others. The most important message to take from this page is that you should consider the total cost of ownership of a machine. Purchasing a CNC machine is not about the bottom line at the point of sale like it is when you buy a power tool in the hardware store. A CNC machine is a production system that requires time and effort and consideration. A huge part of the customer journey is the support aspect. Anyone can sell CNC machines – it is another question however to support CNC systems.

We ask all our customers to consider the expectations you have in terms of the machine performance as it will help us help you identify a machine that is fit for purpose within budget constraints. If we cannot spec a system that we feel is fit for purpose within a budget constraint of a customer – then we decline to provide a machine – it generates a false economy. A cheaper machine will save you money now – but if it is not fit for purpose then over the lifetime of the machine any savings will not transfer through.

Machine Size

The biggest machine we provide in the tabletop format is the JBEC 1259012 Professional system with a machine travel of 1300mm x 960mm. This is roughly a half sheet machine. There are other offerings out there that retain the tabletop design and go up to as large as 10ft x 5ft. These are perfectly viable systems. However, there are a few things you need to look out for. Once you start to increase the size of a tabletop machine it can cause issues with frame-twist and bed misalignment. Often a larger 8 x 4-foot type tabletop CNC system will have to be supported by a careful setup table or bed to maintain alignment. Any twist of change in the frame position can cause drives to seize and will prevent accurate machining in the Z direction across the machine travel. If you decide to opt for a tabletop machine in the 4-foot x 4foot and 8foot x 4-foot range – make sure you see the system in the flesh and assess the bed stiffness.

Our biggest router comes out of the delivery van and is working within minutes of being installed. There are no special requirements for the desk/table support. Any standard table will suffice in terms of alignment.

Machine Speed (feed)

The feed rate of the machine is the speed at which the machine can move in the X, Y and Z axes. Speed is a very important parameter for a number of reasons.

The feed is an excellent indicator of the overall drive system power and efficiency. A drive system consists of the motors and their associated electronics and the linear drive mechanism itself. Ideally, a drive should be as stiff as possible in all directions except the direction of motion. Any stiffness or inefficiencies in the drive direction will reduce motor torque. Ant loss of stiffness in any direction other than the drive direction will result in lost accuracy.

The feed is an excellent indicator of the quality of the motion control system and the motor drive electronics your CNC machine uses. A reliable motion controller will generate much smoother and more reliable pulse signals to the motor drives and give the system more power.

The CNC drive system generates a linear motion to carry out CNC machining. Typically for MDF and most plastics, a feed rate well in excess of 1,000mm/min is required for efficient machining. CNC router spindles need to spin fast to get good torque from the motor. This requires a fast machine movement rate to establish stable machining without generating excess heat at the cutting zone. As such there are typically two parameters given with the spec of any CNC router – the rapid feed (which is the fastest speed the machine can move at when, not machining) and the cutting feed (the max feed rate that the machine can cut at). For example – our machines can move at up to 10,000+ mm/minute (although we recommend 6,000mm/min for normal operation) See here for a quick demo.

The feed will affect the time taken to carry out a specific job. Our professional machines can machine at up to 4,000mm/min in some cases depending on materials and cutters used. If you compare this to a machine that can move at say 1,000mm/min, then there is a 4 fold reduction in the time to produce a part. Extrapolate over weeks of work in terms of hours in the workshop – the difference starts to add up.

Make sure you see the system machining at the specified feed rates. This is very important. For example, you can see the professional machines here machining aluminium at 2,500mm/min.

A feed is an important parameter for efficient machining and a good indicator of the quality of the drive system used.

The Drive System

The drive system is the part of the machine that includes the machine’s slides (that let the machine move in the three X, Y and Z directions) and the drive mechanism (the system that translates the rotation of the drive motors into linear motion).

All our professional CNC machines run on ball screws. Ballscrews are not “leadscrews”. Ballscrews are not “trapezoidal” lead screws. Ballscrews have circular grooved shafts with rolling recirculating bearing elements on the nut. While software can be used to eliminate “backlash” generated when using leadscrews/trapezoidal screws – we believe it’s best to minimise the backlash with hardware – hence we use ball screws where the backlash is at a minimum. They don’t wear out as quickly – are virtually maintenance-free and are THE most accurate method of driving a CNC router.

The efficiency of ball screws is also related to the ability to run the feeds high. Sliding friction in leadscrews typically generate too much loss to run at higher speeds

The drive system is an important factor to consider when choosing a CNC router – ask google yourself and see what the general opinions are. Leadscrews are also cheaper than Ballscrews and will therefore reduce the overall price of a CNC system.

Have a look at the Gallery for some sample images of the ball screw drives we use on our machines.

CNC Drive System Gallery

Examples of Backlash Induced Machining

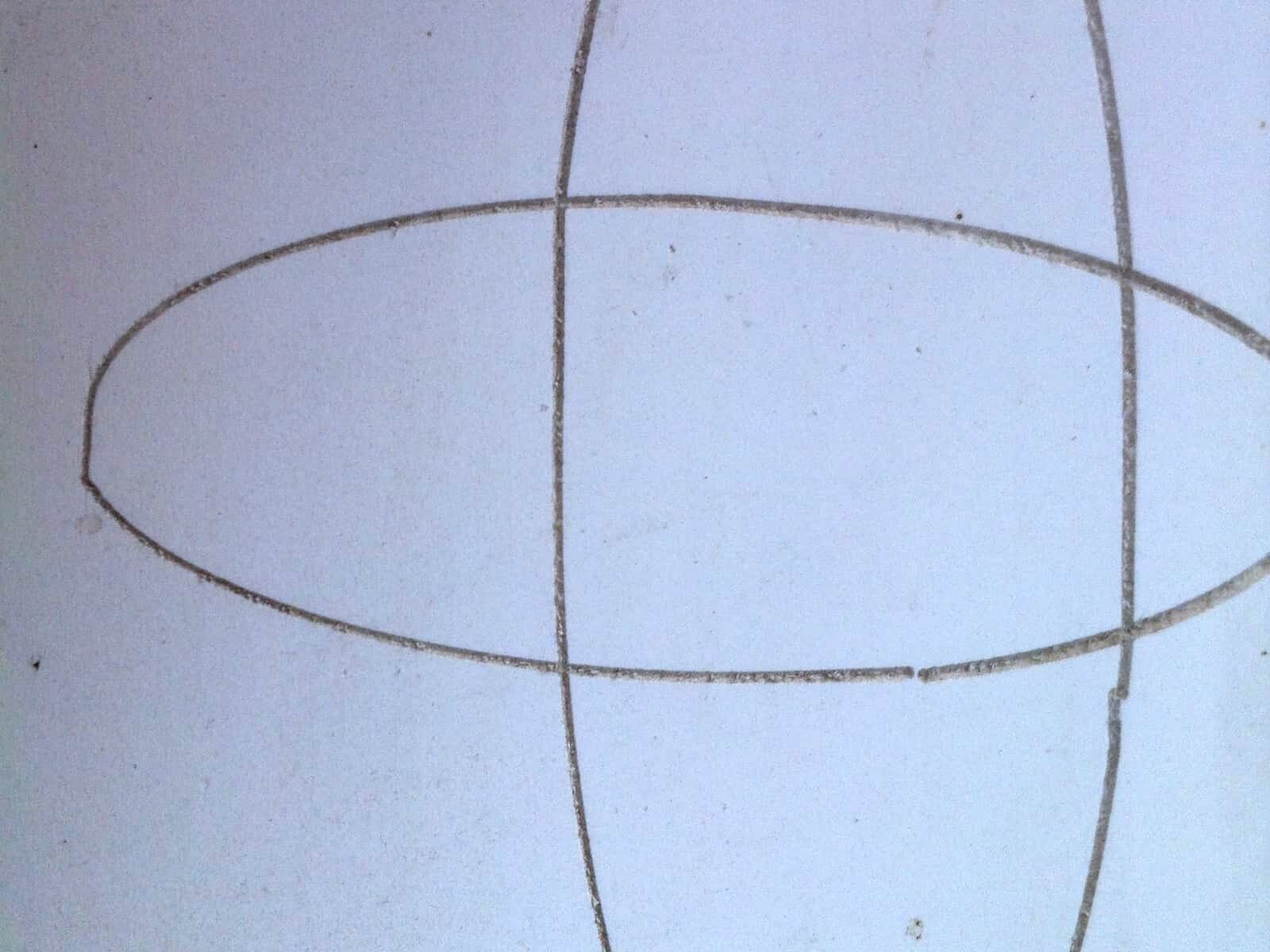

Have a careful look at the images shown here in the gallery to see examples of what happens if a machine demonstrates backlash during cutting. In order to fully test the accuracy of a CNC’s drive system, you have to ask the machine to change its direction of motion in all axes during a cut. A good example to test X and Y is an oval of a circle. Any backlash will show up as an irregular circle or oval. If this happens with a relatively large circle it will be amplified when it comes to smaller text writing. A machine should be able to machine a clean circle and carry out reliable work that is square and even during all cutting operations. In addition to the images showing examples of backlash, the last two images in the gallery were caused by an axis of a machine torquing out due to excess friction in the drive slides

What to look for?

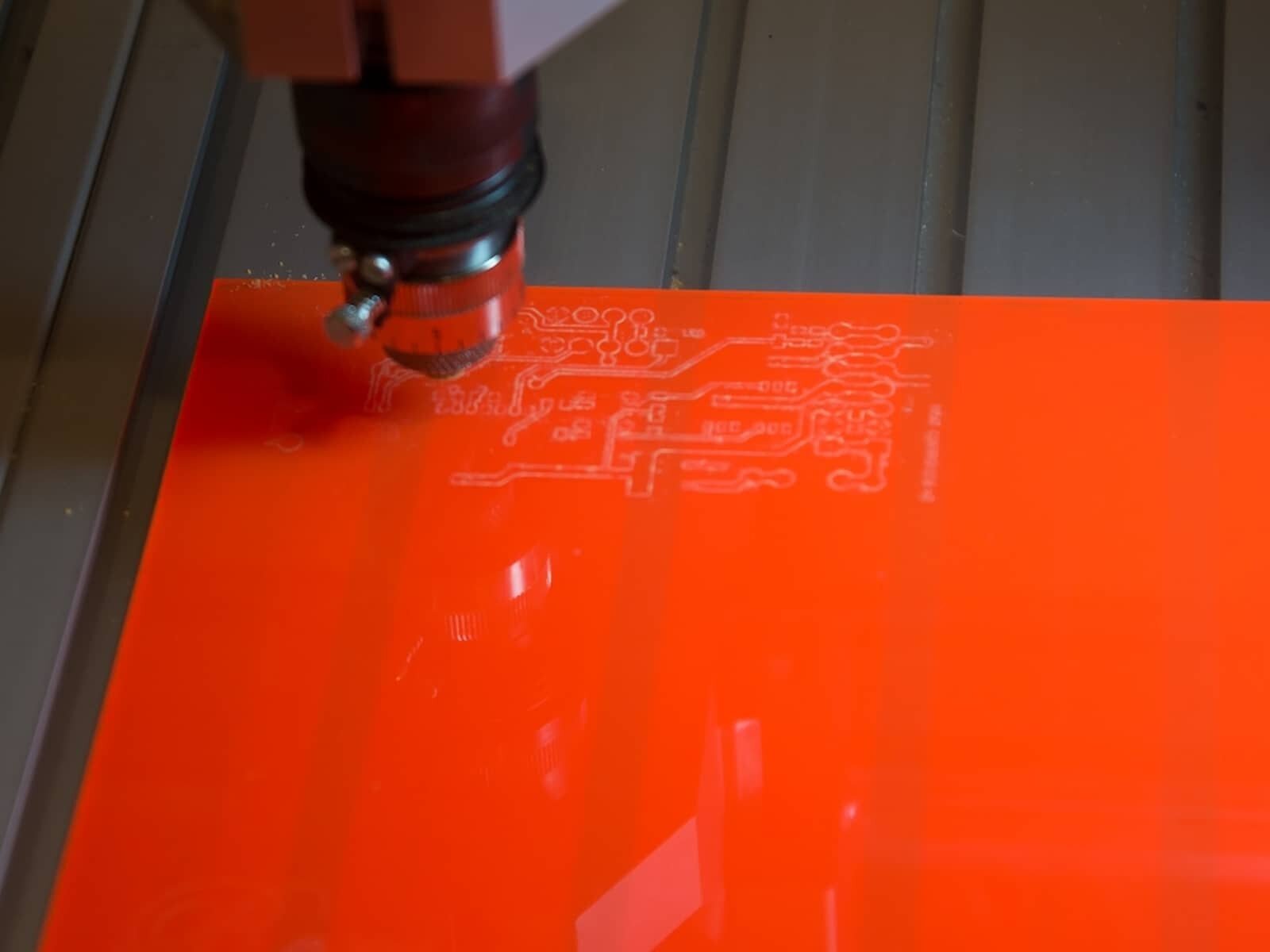

If you view a CNC machine – make sure you are shown machining of circles, ovals and small text. This will be a clear indication of the accuracy of the system. Shown in the Gallery here illustrates some very detailed performance carried out during a (printed circuit board) PCB milling demonstration. The JBEC 604012 machine was set up with a floating head. The floating head is designed to add to the accuracy of the Z-axis but has no effect on the performance of the X and Y-axis. There was no software-induced backlash compensation applied to the machine and the 604012 was run as normal during the cutting operation. Pay special attention to the text that was machined as part of the toolpath provided by the customer. The letters are in the order of mm’s in dimension (as shown by the steel ruler) and show the accuracy that the ball screws give to the machine drives. Please request to see similar performance from your machine before you purchase.

Spindle

In our opinion, if a machine cannot support an HF three-phase spindle then it is not classed as a production-spec machine. A Kress spindle or any single-phase universal type spindle in the 1kW range is considered by us as an entry-level/low-end spindle system.

For production work, be it heavy work in 3 axes or high machine duty cycles, a three-phase spindle system is required. Have a look here at the differences. Pay attention also to the mounting methods used. The HF three-phase spindle is far superior to the Kress spindle.

Again that does not mean everyone needs an HF spindle. You just need to be aware that the Kress spindle is not a production spindle. The Kress is a very popular option for customers who are starting off in CNC or are not doing heavy production work.

Software

You are the user who will be interacting with the machine on an hourly/daily/weekly/monthly basis. Therefore a critical aspect of machine use is the software you interact with.

We specify and support a fully integrated software approach when providing a CNC router. This allows the user to design, generate tool-paths and carry out machining operations quickly and easily. There is no USB flash transfer required as all the software can be installed on a Windows PC. We use a very reliable USB controller and therefore we can install a stable motion control system on any Windows PC or laptop.

Have a look here for some more information. We put a heavy focus on making the customer journey from design to machining as easy as possible.

We feel a CNC software solution should have the following traits

As much compatibility as possible with other CAD/Graphics packages

Reliable operation on a standard laptop/desktop

The CNC control software should have a live view of the machine and toolpath – this makes the setup significantly more straightforward to follow and understand

You should be able to tweak the design, the tool-paths and the machine operation quickly and easily on the one system

System Classification and Comparison

When you look at different CNC router systems be very careful how you compare the different machines on the market.

For example, you cannot compare the STEPCRAFT machines we offer with the Intermediate and professional machines. The two machines are in a completely different price, performance and machine duty cycle category.

For example, you cannot compare the JBEC professional machine running on ball screws, with high power steppers machining at up to 4,000mm/min against a leadscrew system machining at 800mm/min. To compare these two systems purely on price without considering the comparative performance characteristics doesn’t make sense. You have to compare like with like.