Mill-It Range – The Mill-It MEGA

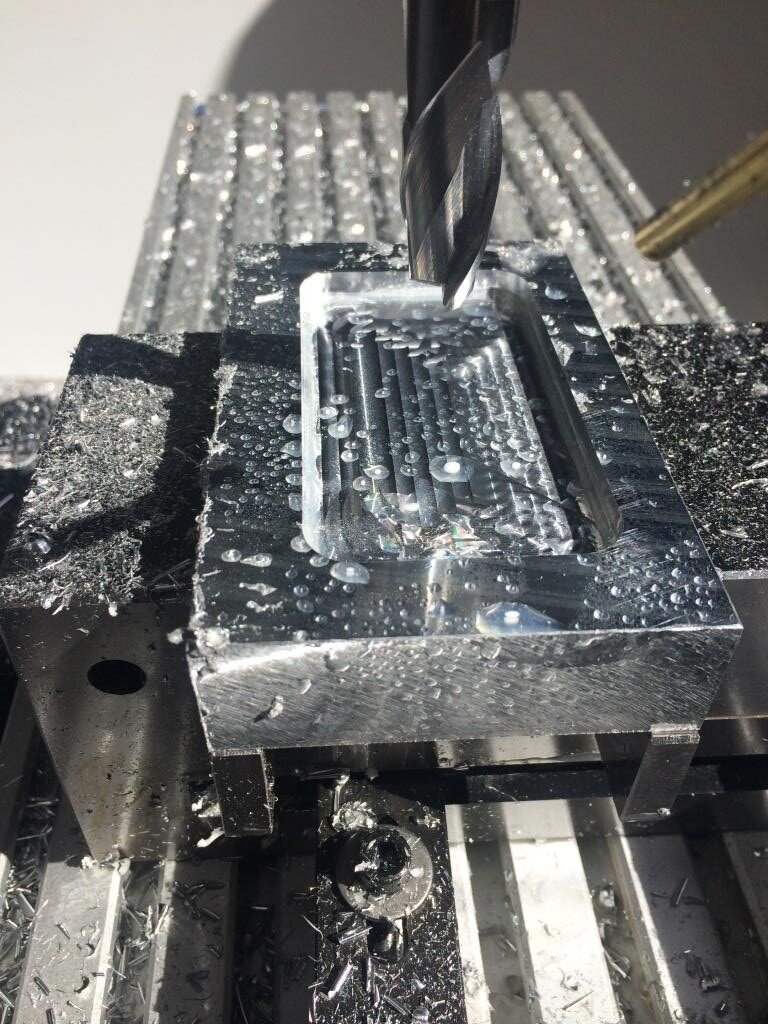

The Mill-it-Mega is ready for release after 2 years of development driven by customer feedback. The high-performance Mill-it-Mega CNC milling machine is now available for pre-order. This machine is designed to make Aluminium prototypes fast and accurately.

The machine has been specifically designed to machine Alloys such as Aluminium fast. With high RPMs and high power spindles coupled to high feed rates, the Mill-it-Mega can prove a really interesting tool for rapid material removal rates and part cycle times. The Mill-it-Mega CNC milling machine is especially to machine aluminium and plastics.

Fully servo-driven ATC model available

400W AC servos

6 ISO 30 tools

Fully automated tool changing

Machining at 10,000m/min possible

High power automated machining is possible

Technical Features

When looking for a CNC milling machine you must consider a number of factors. Have a look below at what the Mill-it-Mega has to offer.

-

The Mill-it-Mega CNC milling machine has a large travel area of X_700mm x Y_320mm x Z_250mm and a Tslot table size of 250mm x 1000mm.

• Very high XY travel for a Milling machine in this class.

• 700mm x 320mm in X and Y.

• 250mm distance between the bottom of collet and top of the table

• Anodised aluminium Tslot table is 1000mm x 250mm

-

The Mill-it-Mega CNC milling machine carcass is incredibly rigid, robust and stiff which is vital for a good surface finish during machining.

• The main structure is the steel welded frame

• The completed steel frame is fully heat-treated

• The frame is filled with polymer concrete resin

• The frame is datum skimmed on all assembly and rail surfaces

• The result is one of the stiffest frames of its kind.

• The stiffness can be seen from the milling results

-

The precision milled interplates between the X and Y axes are machined in a vertical machining centre. All edges are datum machined to maximise the alignment during assembly. 25mm thick Aluminium sections maintain the machine’s core stiffness.

• 25mm Aluminium plates for high stiffness

• All plates precision milled on a VMC

• All assembly edges datum machined

• Designed for easy assembly

• Straight forward adjustment to ensure X is square to Y

• Very high quality, accuracy and stiffness in the coupling of the X to Y-axis

-

The standard config of the Mill-it-Mega CNC milling machine is Nema 34 4NM steppers with IP54 rated sealing caps on the ends of the motors. High stepper motor drive voltage results in high torque.

• Stepper motor torque directly related to operating voltage

• Mill-it-Mega runs on high powered 75V DC stepper drives

• IP54 rated NEMA 34 4NM motors (rapids up to 4000mm/min)

• All cables EMC shielded and high-quality shroud also

• High power Delta 400W Servo option available with rapids of up to 10,000mm/min

IP67 rated high-quality inductive limit/home sensors

With a machine like this often coolant in either flood or mist configuration will be needed. The IP67 rated induction sensors are very robust and of high quality.

• IP67 rated sensors

• 12V DC operating inductively so very reliable

• High quality sealed can connector to sensor

• PUR cable coating for very long cable life in harsh environments

• Each axis has one sensor

-

The Mill-it-Mega CNC milling machine standard spindle options are 12-24000RPM spindles. These spindles are all air-cooled and are excellent for machining alloys at high speeds and high material removal rates.

0.75kW 2kW and 3kW options

Collets: 0.75kW has ER20 | 2kW has ER25 | 3KW has ER32

All spindles have double angled contact bearings in the nose and tail

All spindles are fully balanced after a 12 hour run-in period

All spindles come with a fully balanced collet nut

Driven through a VFD so all fully on/off and speed controlled with software

0.75 and 2kW run on a single phase. The 3kW needs three-phase

All spindles have full stated power output down at 12000RPM. These spindles are well suited to high feed rates with cutters even as low as 6mm. Typically milling systems with spindle speeds less than 8000RPM required very slow feed rates when using smaller cutters.

Fully up-gradable – all spindle options fit the mount on the machine so its no problem to start small and upgrade later

Specifications

Mill-It MEGA CNC milling machine specifications.

| Travel in X Y and Z axis | 700mm x 320mm x 250mm |

| Carcass build configuration | Welded steel frame, heat treated, filled with polymer concrete resin and datum skimmed on VMC |

| Tslot table size | Anodised Aluminium Tslot table 1000mm x 250mm, Tnut type M6, Very high quality Aluminium Tslot table. |

| Overall footprint | 800 x 1300mm (With the table in the middle) |

| Bottom of collet to Tslot table height | 250mm – Travel brings collet to the Tslot table |

| Rapid Feed rate | 3,500mm/min (58mm/sec) High acceleration rates of 350mm/sec/sec possible depending on what is loaded on the table. This allows very fast 3D prototyping in Aluminium. With the servo upgrade 10,000mm/min and higher achievable. |

| Spindle Options | 750Watt (Er20 collet) | 2kW (ER25 collet) | 3KW (ER32 collet) (Three phase required for the 3kW spindle) All models very high quality spindles fully balanced. ATC options available on demand. |

| Spindle RPM and torque | All spindle have full stated power at 12,000-24,000RPM. All fully software controlled for on/off and speed in RPM. |

| Machine Weight | 250kg – due to very heavy stiff carcass filled with polymer concrete resin. |

| Software Compatibility | Ethernet connectivity to UCCNC controller |

| Drive system Electronics | 75V DC Nema 34 4NM stepper motors (Very high speed Delta servo options available) |

| Limit and homing sensors | Highest quality IP67 homing sensors fitted. Sealed high quality PUR cable routed the limit switch cables to the controller and they run on 12VDC. Very robust. |

| Control System | Machine comes as standard with full controller system with integrated 3 Axis and spindle control – carcass only available on request |

| Linear motion system | Profiled linear rails all mounted on Datum surfaces precision CNC milled. |

| Coolant | Fully compatible with the Fogbuster sprayer system and can be configured to run flood coolant also |

Mill-It MEGA Gallery

Here are some photos of the Mill-It MEGA milling machine. We have even more photos here …