Horizontal Machining Centre ⚙️

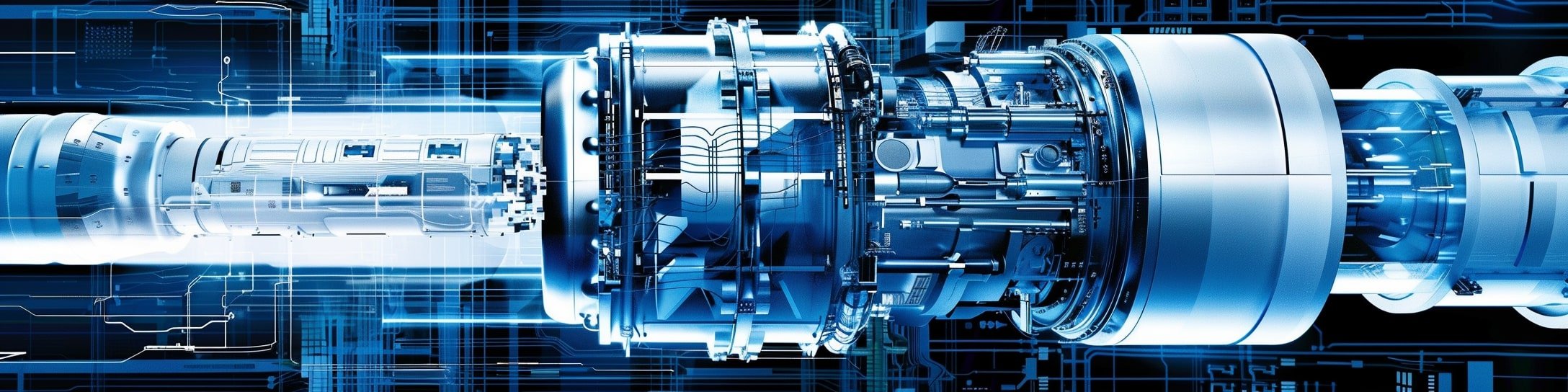

A horizontal machining centre (HMC) is a type of CNC (Computer Numerical Control) machine tool designed for precision milling, drilling, and other machining operations with a horizontally oriented spindle. The horizontal configuration enables easy chip evacuation and makes it ideal for machining large or complex parts that require multiple faces to be machined in a single setup.

Key Points about Horizontal Machining Centres

Horizontal Spindle Orientation: In an HMC, the spindle is oriented horizontally, allowing for better access to multiple faces of the workpiece, which can often be machined in a single clamping.

Automatic Pallet Changers: Many HMCs come equipped with a pallet changer system, enabling operators to load and unload parts on one pallet while the machine operates on another, significantly boosting productivity.

Multi-Sided Machining: The horizontal setup allows easy rotation of the workpiece for multi-sided machining, making HMCs ideal for complex parts that require machining on several faces.

Efficient Chip Evacuation: The horizontal orientation helps chips to fall away naturally from the cutting area, reducing the risk of chip buildup and improving cooling efficiency.

Applications

Horizontal machining centres are widely used in industries such as aerospace, automotive, and heavy equipment manufacturing to produce parts like engine blocks, gearboxes, and structural components. Their ability to handle large, complex parts with high precision and efficiency makes them particularly valuable in high-volume production environments.

A horizontal machining centre (HMC) is a CNC machine with a horizontally oriented spindle, designed for efficient, multi-sided machining of complex parts with effective chip management and productivity-enhancing features like pallet changers.