5.0 Robotics

StoneyCNC is the EU Competence centre for the 5.0 Robotics range of CNC router systems. Check out the Model 8 and Model 16 Executive range here!!

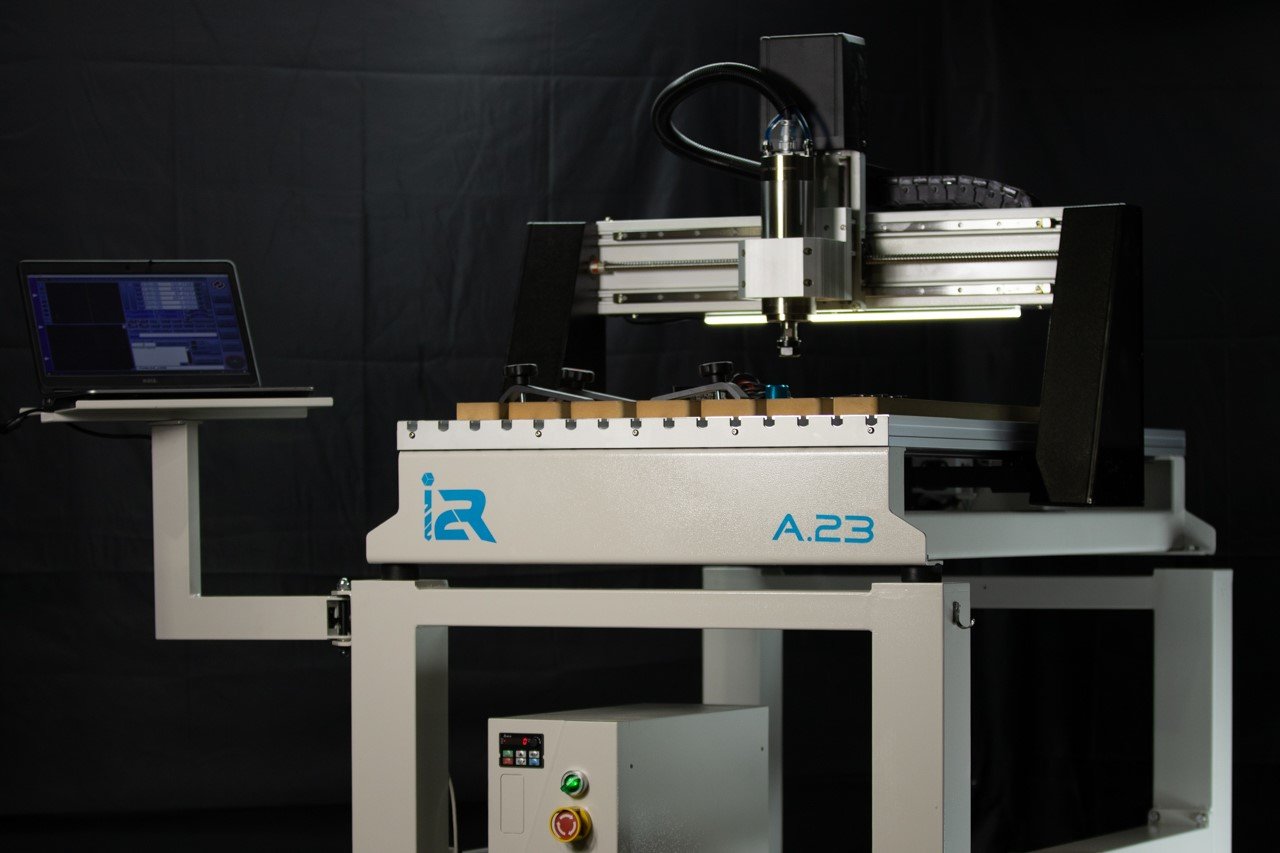

StoneyCNC is the EU COMPETENCE Center for the 50Robotics and i2r range of CNC routers

Machines stocked and available from our HQ in Dublin in EURO!!

Machines shipped from Dublin to UK in £, with UK VAT invoice, all customs processes fulfilled. No customs process required on the UK side.

Welcome to StoneyCNC

Welcome to StoneyCNC, your go-to resource for all things CNC. This site is our main information site where you can research all your CNC needs. To purchase items, or find out prices, you should visit our separate dedicated webshop using the order now button below.

We provide a range of CNC milling machines and CNC routers to the UK, Europe and globally. We offer entry-level CNC systems right the way through to full production CNC equipment.

We also provide a variety of CNC machining services, manufacturing consultancy and other CNC services. Our core focus is quality, value and making the users’ interaction with our machines as easy as possible – even where this is not already in place. We can turn your Desktop/Laptop into a fully integrated CNC control station for your machine.

What do we do?

StoneyCNC offer CNC cutting machines and production solutions – Professional tabletop CNC router – CNC milling machines – High performance small format CNC routing machines - Large format wood processing machines – Premium high-end 5 axis machines.

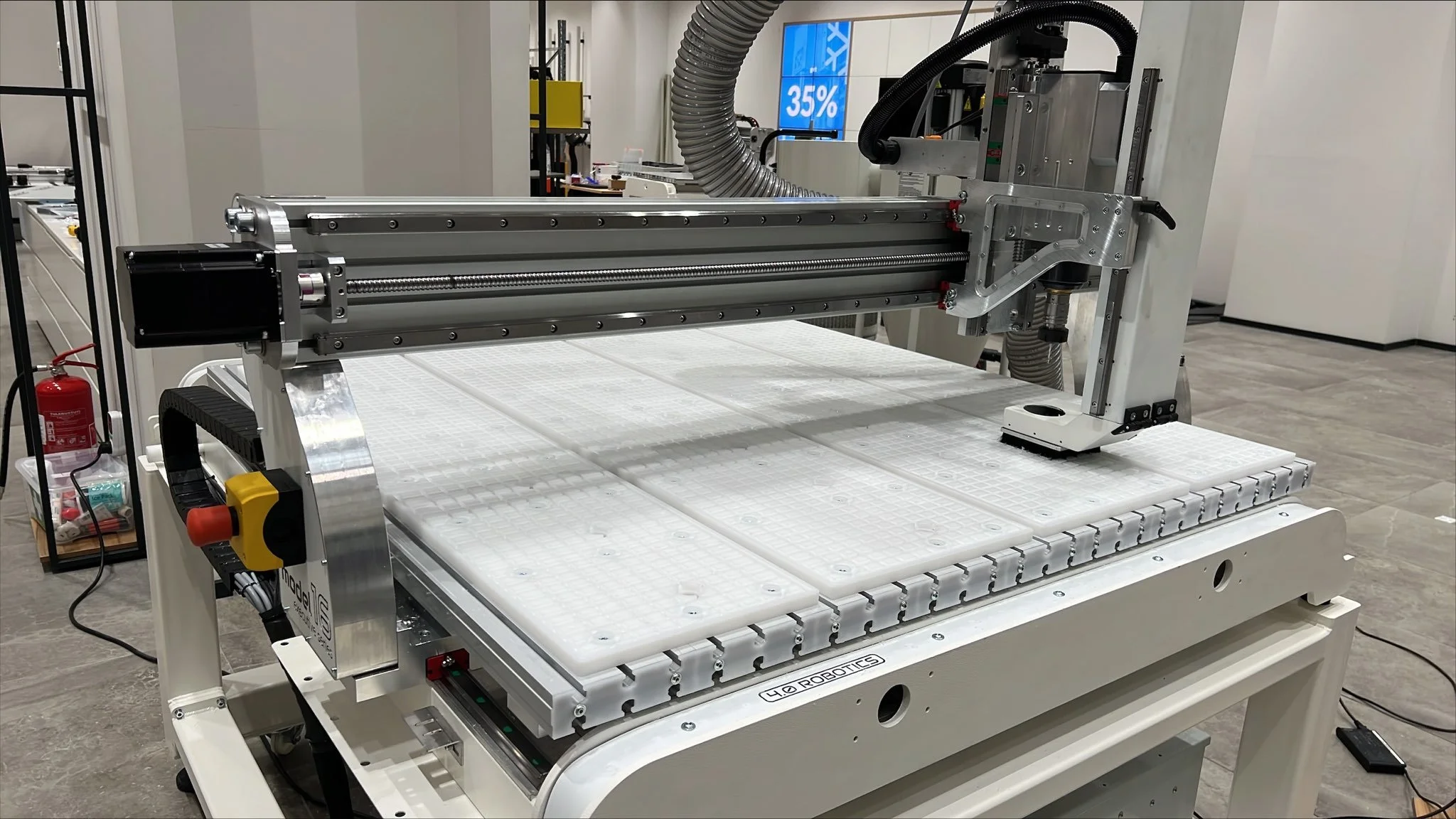

5.0 Robotics CNC manufacturing systems - the new digital age of manufacturing

BRAND NEW! 5.0 Robotics Executive CNC Router

Our “Really SMART” Hybrid CNC Milling Solution

The reasons why SMEs and entrepreneurs haven’t been able to adapt CNC technology are lack of know-how, price and usage complexity of the machines and lack of qualified personnel.

The Executive series is a solution to all of these problems. Our focus is on high end usable machine tools.

Large Format CNC Systems

JKR CNC Routers

Your large-format solution.

JKR CNC routers - Your large-format solution

Find out large format CNC Systems here!

The JKR CNC router systems are a high quality affordable large format flatbed router technology. We offer the JKR2513 (8 x 4 foot) and JKR 3020 (10 x 5 foot) platforms. All servo-driven with ball-screws on all axes.

Visit the above link to view our Large Format CNC Router range.

CR ONSRUD

High-end premium large-format CNC.

See more of our CN Onsrud Premium High-end CNC Systems here and contact Stoney CNC with any enquiries.

The CR ONSRUD range of high-end premium 3 to 5 axis CNC router systems offer large format CNC platforms capable of processing alloys as well as typical wood-based materials.

Contact Stoney CNC for details.

CNC Milling Machines

Mill-it-MEGA High-Performance CNC Milling Machine

Click on the link below for intro details about the Mill-it-MEGA high-performance CNC milling machine. Contact us at Stoney CNC for any further information.

Mill-it-MEGA CNC milling machine. Powerful knee mill design!

SYMBIOSIS HYBRID Router-Mill Machine

Built from the ground up here, at Stoney CNC, our SYMBIOSIS Router-Mill Hybrid machine range. Contact us for more assistance.

SYMBIOSIS at home milling aluminium all day!!

Accessories & Extras

Photo Galleries

Custom light designs - more images …

CNC machined RC components - more images …

CNC plywood tables - more images …

Letters and signs - more images …