JBEC Professional CNC Routers Overview

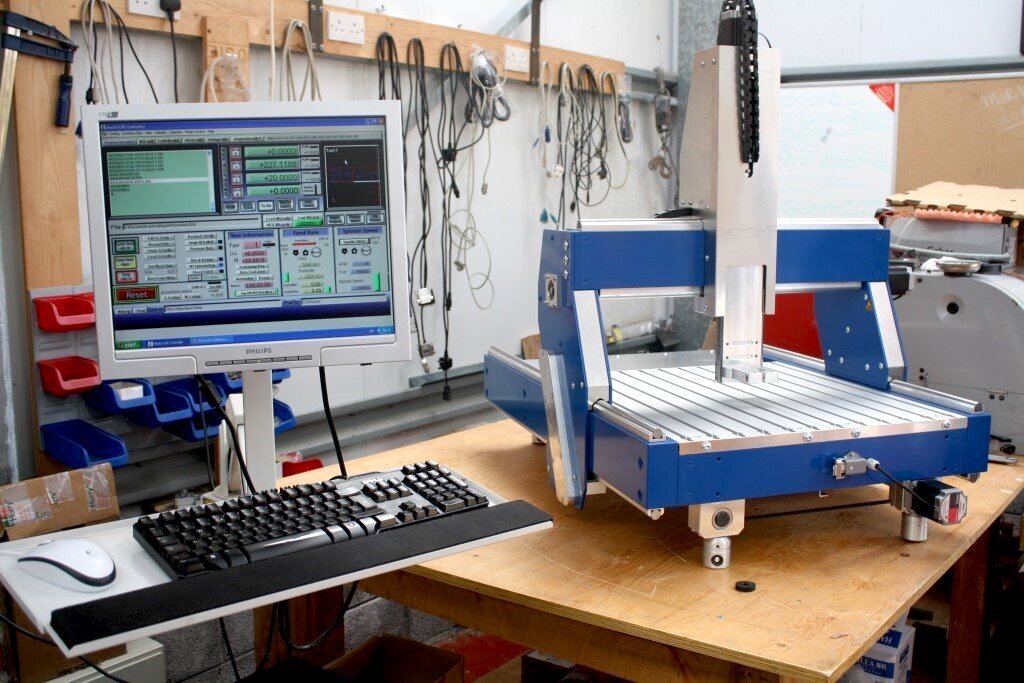

Welcome to the section of our site dedicated to the JBEC professional CNC router machines. The JBEC professional machine series are high-performance tabletop CNC router systems. The machine frames are built in a dedicated machine-building factory in Germany and use only the highest quality parts and components. The core machine frame is the result of the ongoing collaboration between StoneyCNC, JBEC, and our German partners.

The JBEC Professional CNC Router 604012

The JBEC 604012 machine is the smallest machine we offer in the professional series. The specified travel is 600mm x 400mm in X and Y. If you take care you can realise up to 660mm x 420mm.

The JBEC Professional CNC Router 106512

The JBEC 106512 machine is the medium-sized machine we offer in the professional series. The specified travel is 1000mm x 600mm in X and Y. If you take care you can realise up to 1060mm x 670mm.

The JBEC Professional CNC Router 1259012

The JBEC 1259012 machine is the largest machine we offer in the professional series. The specified travel is 1200mm x 900mm in X and Y. If you take care you can realise up to 1350mm x 970mm.

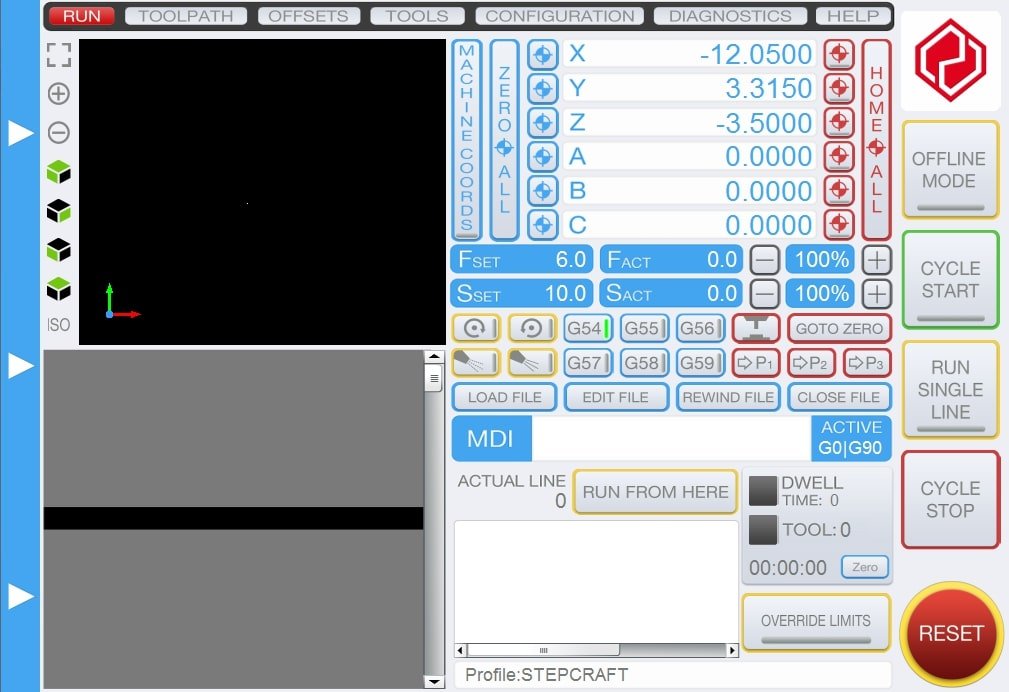

JBEC Professional CNC Router Software

We don’t believe in a “disconnect” between the machine and the software used to interact with the machine. Therefore we provide and support a fully integrated software solution for our machines.

Main Machine Features

Extremely stiff blue powder-coated box section frame construction.

The same box section construction is used for the gantry tower design for extra rigidity.

Ball screw drives on ALL axes (required for full 3D machining as high-speed 3D machining cannot be realised using lead screws).

All drives are positioned outside of the working area for protection against contamination from swarf and dirt, etc.

24V DC no Volt release industry-standard control panel (a safety pre-requisite – absolutely required to conform with CE regulations – a machine like this is designed for industrial applications and is considered dangerous without it).

Full cable management in the cable chains – is very important for the long-term stability of machine operation.

Adjustable height feet for levelling on an uneven table.

Large Z-axis throat height and adjustable height of the motor mount – allow for long cutters – excellent for 3D machining.

Fully integrated CAD/CAM and CNC control software (fully supported) for maximum efficiency between design and machining – all on one workstation with a live machine view. No USB flash drive transfer is required.

Specifications

These specifications are common to all JBEC CNC routers. For specific travel, machine size and weight/passage height, please see the specific router page.

Repeatability tolerance (machine accuracy): 0.02mm

Rapid feed rates: 10,000mm/min rapid feeds possible – 6,000mm/min recommended

Machining rates: up to 4,000mm/min depending on materials and cutters used

Motor specification: High torque stepper motors (servo option available, please enquire)

Passage height (height between Z axis fixture and T-slot surface): 150mm

Machine bed: T-slot aluminium with 4 clamps

Photos

…

Videos

Here are some videos showcasing the JBEC professional table-top CNC router series.

JBEC Professional Machines in Action

The video here shows a general overview of the machines working on a variety of materials. Pay special attention to the material feed rates (speed of machining in X and Y) as this is a very important performance parameter when considering your machine. With a CNC router, you want to be able to mill materials well in excess of 1,000mm/min.

We rapid our systems at 6,000mm/min (we can run up to 10,000mm/min but recommend 6,000mm/min) and can machine at up to 4,000mm/min depending on the materials and cutters. We offer three-phase spindles for production work (no brushes and heavier tapered bearings in the spindle head. Note: Spindle still works on single-phase supply) and more importantly, the machine has the platform stiffness to support a three-phase spindle option. If a machine cannot support a 3-phase spindle option it is not an industrial spec production system.

Please see our technical specifications above for more details about the machine.

Contact Us with Your Application in Mind

We like our customers to see exactly what they have in mind before they purchase a machine. We can organise a viewing at our workshops – or we can machine a sample for you and send you videos and images to help you with your decision. See here and here for video examples. See here and here for photo examples. Once you have had a look around our site please contact us with your application in mind. Please see our technical specifications above for more details about the machine specifications.

Frequently Asked Questions

-

See here for some customer samples and case studies of the JBEC routers in use.

-

If you have a question that has not been answered here or need more information on any information/answers provided already, please complete the form below (click the “Ask a Question” button) and we will happily reply to you and extend this page or FAQ section.