CNC Plasma System

Standard and custom CNC Plasma cutting systems

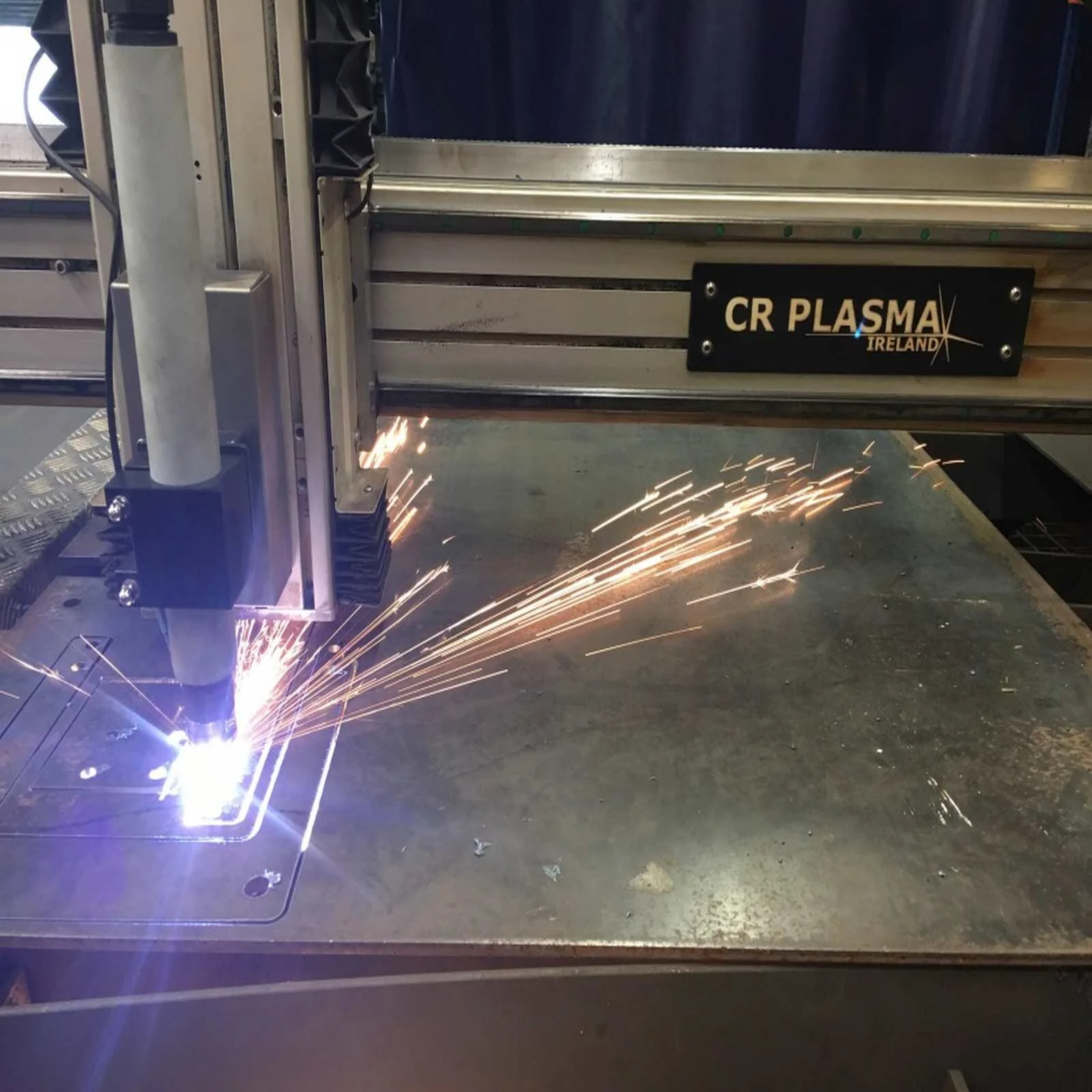

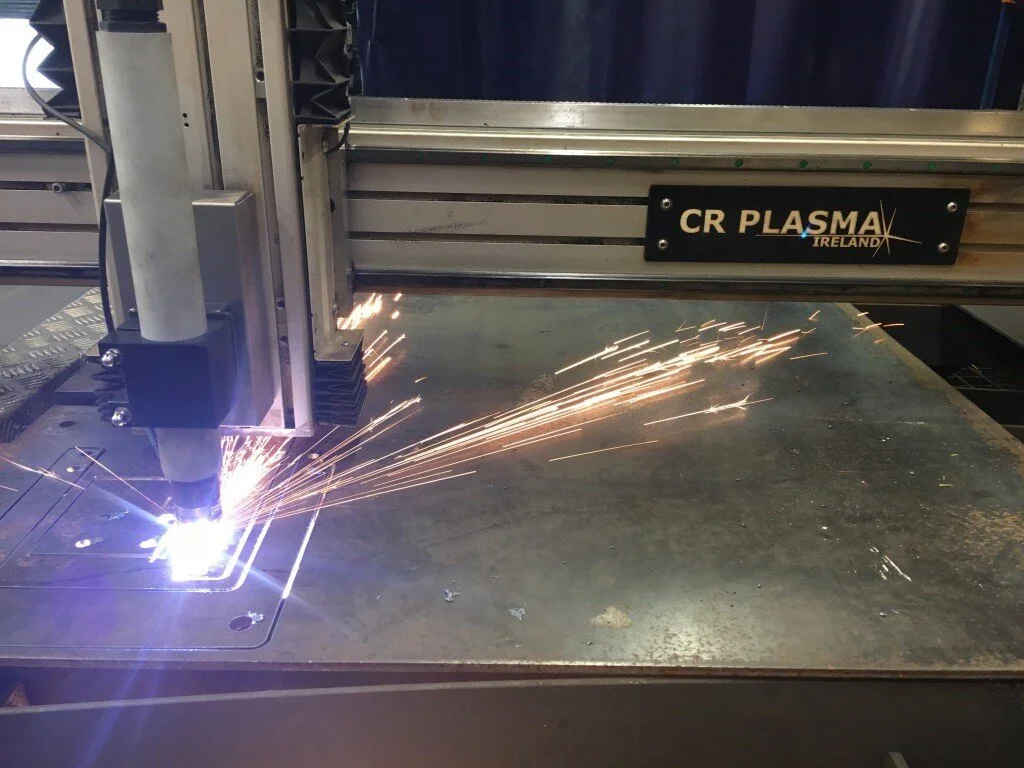

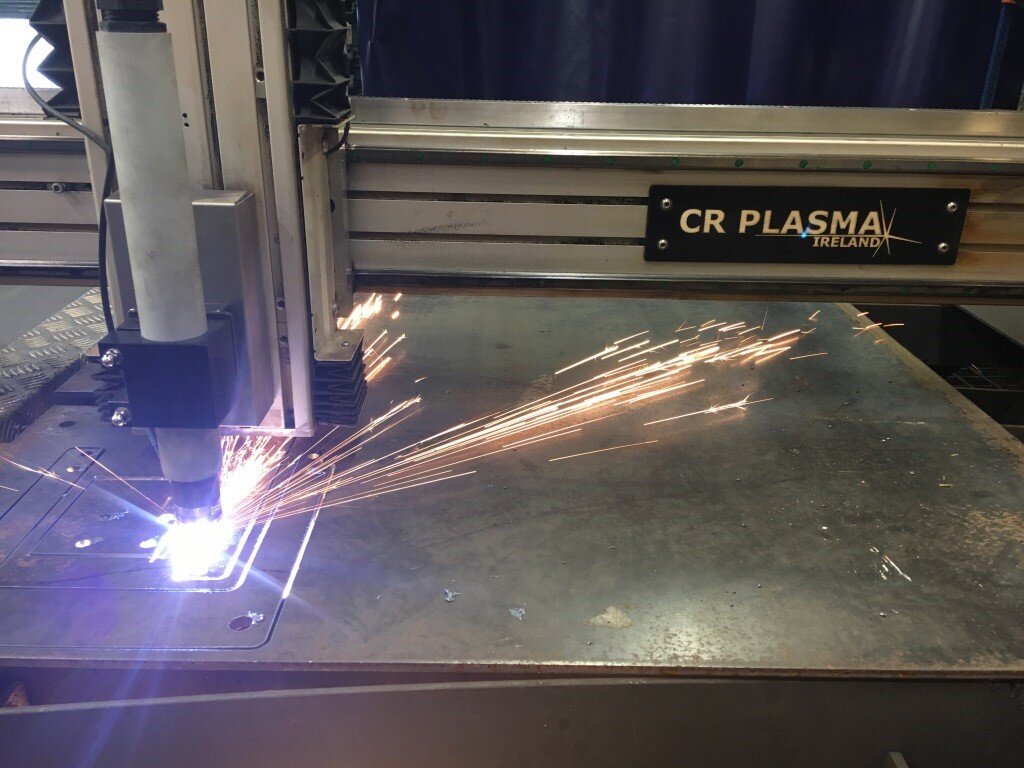

Here, at Stoney CNC, we offer a range of standard industrial plasma cutters. Click on the link below for more information on the CR Plasma Powercut 10 x 5 CNC plasma cutting system.

The Powercut plasma cutter comes in 8 x 4 foot, 10 x 5 foot and 4000 x 2000mm sizes. We can also build custom machines (see more below).

Find out more details here on the Powercut 10 x 5 Machine Series.

POWERCUT EDU | The Educational Plasma Cutter

The POWERCUT CNC plasma cutter is available as an educational package with a full safety system integrated as a standard.

Plasma cutting systems

We now offer the option to upgrade any 3 axis CNC package to be compatible with plasma cutting technology. The machine shown here was designed specifically for a customer who wanted both 2D cutting to very high accuracies and who also wanted a custom made tube cutting system.

A move towards automation

The parts were all previously fabricated using conventional techniques. We were approached and asked if we could provide an automated system to make the parts given the demand for volume production was growing. We worked with the customer to provide the system shown to help make the manufacturing of the parts as efficiently as possible.

Customer Journey | Integrated Software control

An important factor for us was the customer journey when using the machine, as well as the machine itself. As the users of the system did not come from IT backgrounds and had limited experience on computers, a big challenge for us was in the training and in the provision of a system that was as easy to use as possible. As per all our systems, we focused on a dedicated integrated software approach where all aspects of the machine use (Design, CAM and control) were hosted on the control PC. This way we could ensure a smooth journey for the users through the various steps to use the plasma cutting system.

We designed the machine to operate in two modes:

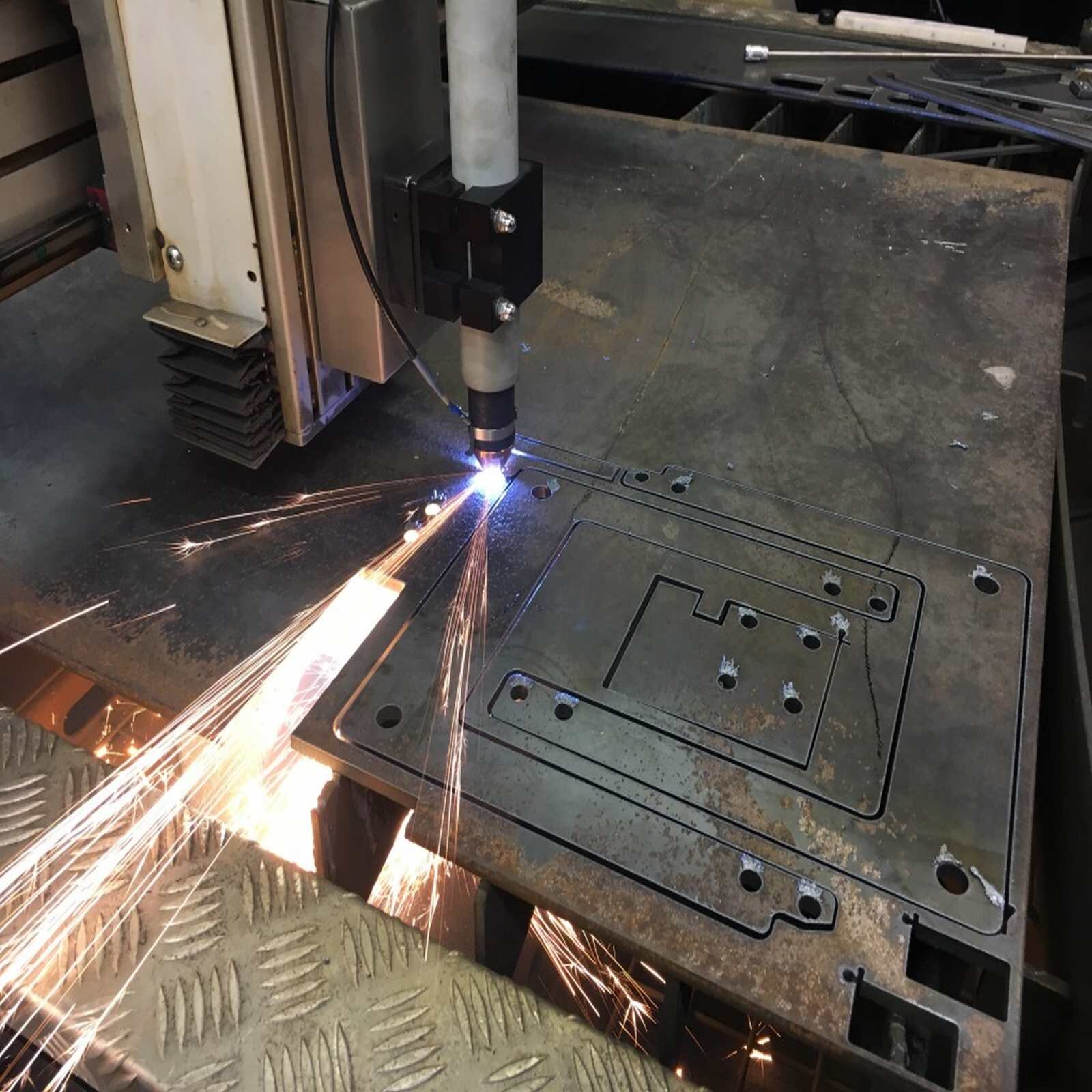

Configuration A Standard 3 axis plasma cutting where the 2D shapes are cut out using conventional CNC approaches to 2D cutting. The benefits here clear as the time taken to make these parts by hand was significant when compared to the CNC controlled plasma

Configuration B Custom 4 axis tube cutting configuration where a 3D part shape was extrapolated into a toolpath on the 4 axis system to reproduce the 3D tube pipe shape. Initially, the plan was to machine one part per cycle, however, it was possible to make two parts with two cutting profiles using carefully setup workpiece clamping and toolpath generation. The results were time-saving and minimised waste material

Torch Configuration The 65 Amp model Hypertherm torch was used and operates with full THC control on the Z-axis.

Plasma system operating n 2D mode & CNC Plasma cutter in 4 axis tube cutting mode

CNC Plasma cutting software

The Plasma cutter works in the same way as a standard 3 axis CNC router. We run the plasma cutters using the same Mach3 controller as our other CNC router systems.

SheetCAM is required to generate the toolpaths for plasma cutting as the torch (equivalent to the spindle) must be turned on and off between each cutting profile.

The 4 axis cutting toolpaths are generated from 3D CAD geometry and are programmed in house using our own approach to 4 axis cutting.