FogBuster Coolant Sprayer System

The FogBuster system is designed to produce a stream of air and coolant together without creating a fog or atomized mist. The low pressure, high volume sprayer provides a targeted spray to the cutting area and the workpiece without atomizing the coolant droplets. Therefore no unwanted (and potentially harmful) coolant mist is generated where the sprayer is operating. This makes the environment where the system operates significantly safer.

The system is compatible with a wide range of coolant types and works well even at pressures as low as 10 PSI. All the coolant is targeted at the cutting area through the brass sprayer nozzles. The absence of airborne oil-based pollutants reduces the health risks associated with mist coolant systems significantly.

The system provides a very clean and controllable way of directing coolant to a cutting operation. The sprayer nozzles have adjustable valves that can be used to reduce the amount of coolant to a minimum.

The FogBuster can also be used on conventional machines with excellent results and can even in some instances replace flood coolant systems

Fogbuster System Spray

Fogbuster spray does not atomise but remains in droplet form

Conventional mist coolant spray

Conventional mist coolant system generates air-borne pollutants

Sprayer systems and CNC router

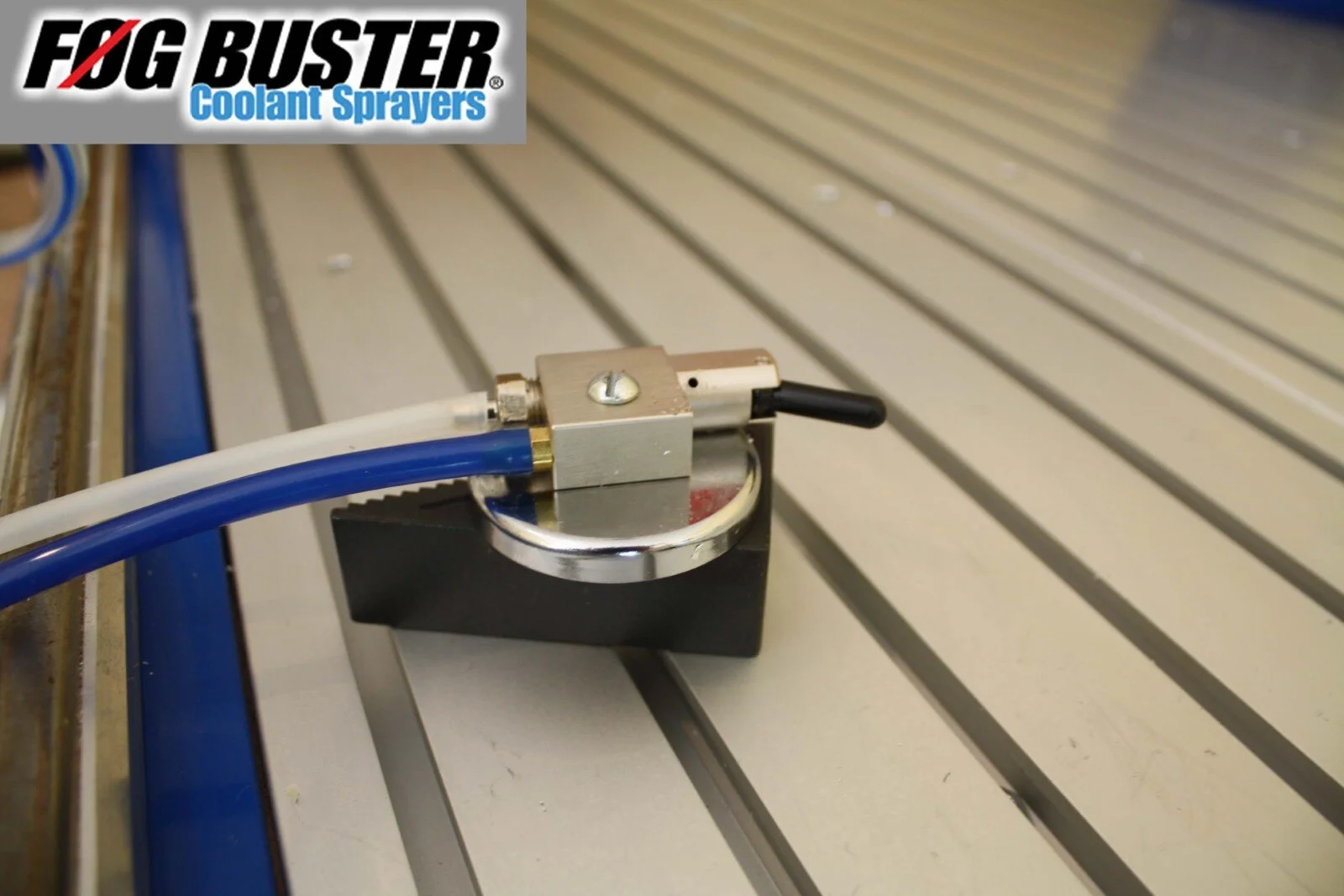

The FogBuster Coolant Sprayer system is available in both Half Gallon and Full Gallon versions. Both versions can be configured in a dual nozzle or single nozzle mode. The systems can significantly improve the potential to machine aluminium on a CNC router. Have a look at the video to get a feel for how the system works. The supply can be manually turned on with the provided valve or can also be configured by the software with an electronic solenoid valve. Please note you cannot operate our CNC routers with a sprayer/misting nozzles in the standard configuration as any stray coolant run-off can migrate to the electronics control bay and be extremely hazardous. We can provide the CNC router systems with an external control box to allow you to run a spray coolant system.

The machining of aluminium and light metals

The machining of aluminium is a hot topic when it comes to CNC routers. A CNC router is not a big milling machine. The routers can be used to machine aluminium as long as the machine is used appropriately with careful attention to the tool-paths. To machine aluminium, you need (at least) to run an airline to the cutting zone to help with chip clearance. Chip clearance is a big issue with aluminium machining as chip build-up and friction effects at the cutting zone cause problems.

Running with a dual sprayer/misting nozzle is the best approach however – as outlined earlier on this page – running with a mist coolant system requires a standalone electronics control cabinet to prevent coolant ingress to the electronics.